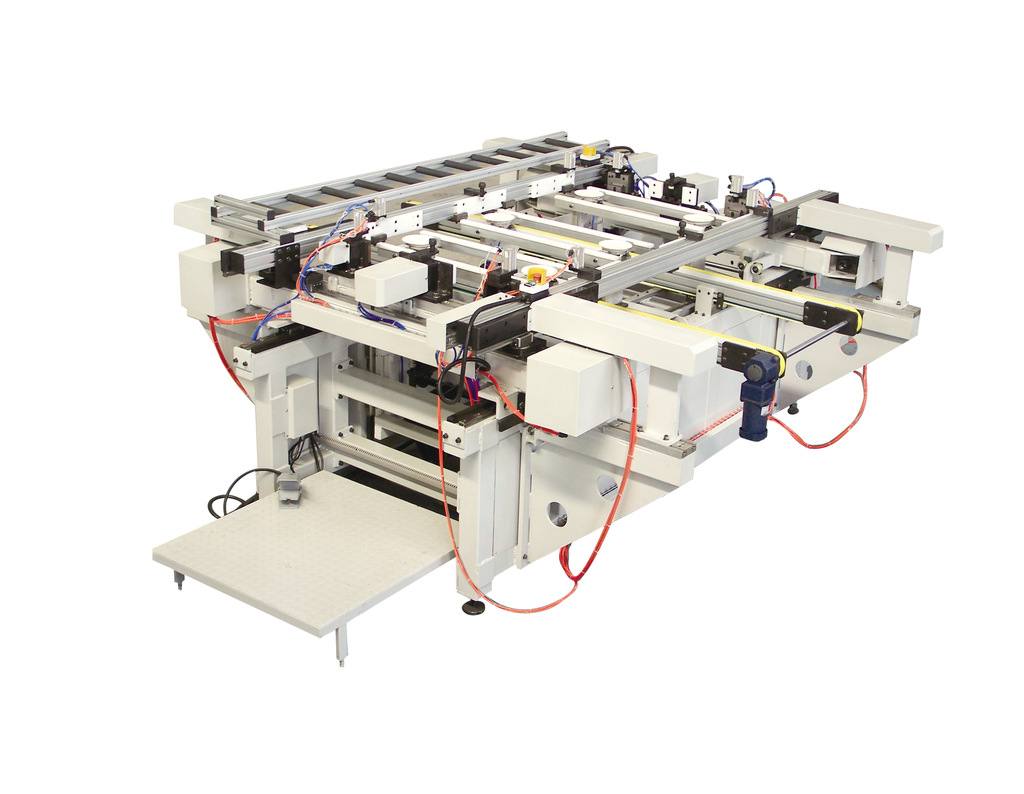

ZKAPF-1全自动太阳能电池板组框机

ZKAPF-1 Automatic Solar Module Framing Machine

设备特点Features of the Machine

1.溢胶量均匀,玻璃面方向无硅胶溢出,背板方向溢胶均匀。

2.玻璃面向下或向上,角码过盈连接

(短边的铝边框的两端已经组装上角码,

并且已经铆接,长边的铝边框的两端已

经冲出凹坑或角码与长边铝边框处于过盈配合)。

3.适用于硅胶密封、罗曼胶带密封的两种方式。

4.同步升降机构,保证了电池板升起高度的稳定精度。

5.电池组件外形尺寸均匀一致,无波浪、腰鼓等不良变差。

6.电池板定位准确,具有可靠的铝边框定位、压平精度。

1.Over gel quantity is uniform,there are no silica gel overflows

in glass direction,over gel in TPTdirection uniforms.

2.The glass of solar panel is upword or downword, the corner

yards interference fit with the aluminum frame. ( Two corner

yards of the short frame have been riveted Well,two ends of the

long frame have been pitted).

3. Be applicable for silica gel sealant and tape sealant two ways.

4.Synchronously lifting framwork to ensure the steady precision

of solar panel rising height.

5.The solar module outside sizes uniform,there are no waves bad

variation.

6.The location of solar panel is accuracy,with reliable aluminum

frame location and press precision.

主要技术参数Main Technical Parameter

型号Model | ZKAPF-1 |

操作方式Mode of operation | 自动Automatism |

最大组框外形尺寸(四角) Maximum groupframe outside dimension (foursquare) |

2000mmX1100mmX(35~50)mm |

最小组框外形尺寸(四角) Minimum groupframe outside dimension (foursquare) |

1300mmX800mmX(35~50)mm |

组框精度Framing precision | 对边尺寸之差 The tolerance of the oppose sides±1mm |

对角线尺寸之差 Diagonal size of the difference±1.5mm | |

四角角度偏差 Angular deviation of four square±0.5° | |

组框动力 Framing drive | 气动Air pressure |

电池板矫平方式 Solar panel planish way | 负压吸附 Negative pressure adsorption |

电池板定位方式 Solar panel location way | 4点推进至设备中心位置 4 points push to the central position |

功率Capacity factor | 5.0KW |

最大外形尺寸 Maximum outside demension | 3000 mm×2700mm×1300mm |

重 量 Weight | 3400Kg |