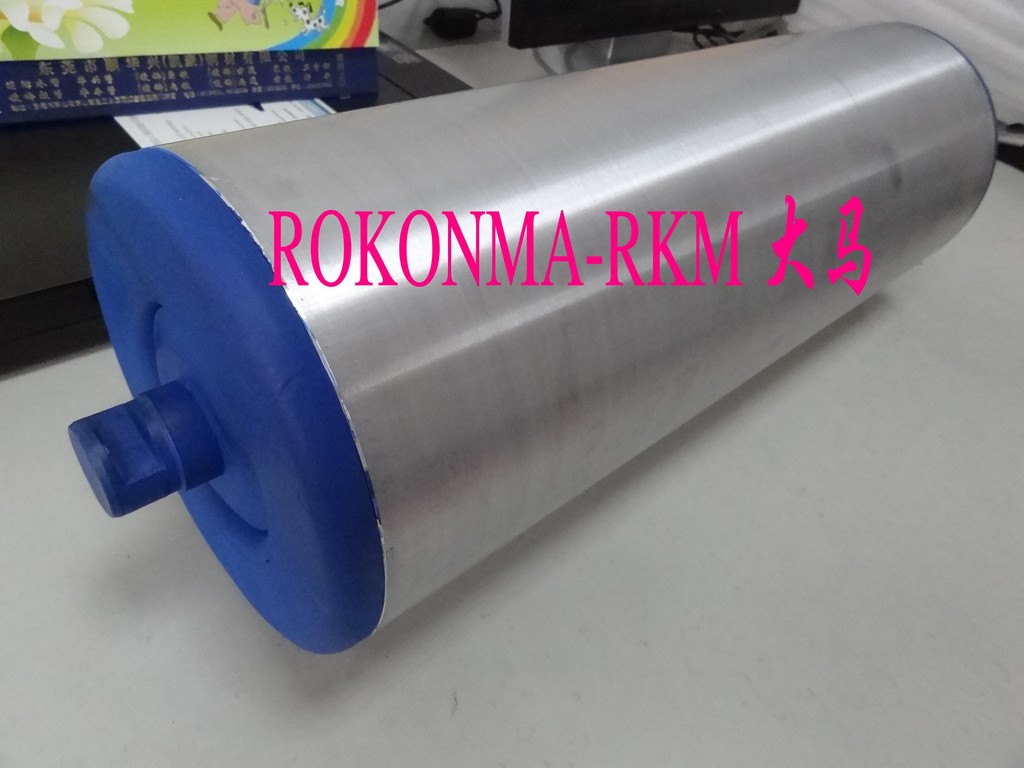

ROKONMA-RKMAluminium Rollers

Aluminium Alloy Shell–Poly Bearing Housings - Roller Features

Shellsare made from a high grade light weight material.

Materialspecially formulated Aluminium Alloy.

End Housingsare an interference fit into the Tube ends & solid in construction.

Material specially formulated Polyester.

Shaftsconsist of cold drawn mild steel-polished round bars in accordance with ASNZS3679 GR300, JIS-G3123 SGD 3 and other equivalent standards. Black shafts -JIS-G 3101-SS400 machined for "step-down" for respective bearing fitting. Particular attention is given to the bearing seat machining and seal. Where necessary the Shaft is stepped, i.e. larger diameter between bearings than at the bearing, to eliminate shaft deflection which causes premature bearing failure.

Shaft Retentionis positive using Circlips both ends to prevent shell being dislodged from the shaft, the circlip grooves on the shaft are accurately machined to tolerance apart.

ROLLER BEARINGS

Rollers are fitted with single row deep groove ZZ type ball bearings with a C3 internal clearance unless otherwise specified. The bearings are factory greased for life and purged with shell alvania EP No: 1 lubricant, this offers minimum roller drag and gives maximum resistance to water wash out.

Expansion and contraction is made possible by 0.25mm maximum clearance at the cir-clips, allowing the shaft to slide in the bearing inner race without loading up the balls on the outer race. The outer race is an interference fit in the housing to prevent the bearing prematurely wearing the housing.

RKM Sealing arrangement

The bearing on the RKM-RS Series are protected on the external and the internal side of the roller by labyrinth seals greased with Shell Alvania-Extreme Pressure [EP]; Lead Free [LF] No:1–Lithium Base lubricants that keep any foreign materials out. Starting from the external side, the various protective elements are:

.a protective anticorrosive shield located firmly on the shaft which acts as

.a barrier against the entry of foreign particles

.a very low friction rubber lip seal to prevent the entry of liquid

.a steel cover cap with a large chamber where any dust particle that might enter is trapped

.a triple labyrinth male preloaded with grease seal is installed

.a triple labyrinth female preloaded with grease seal covers the male labyrinth to form the last barrier of defense before the bearing

Date of Manufactureis embossed on one end of the shaft.

Rim Drag(Rotational Resistance), the free spinning RKM roller ensures a low Power Demand for Conveyors, particularly on Overland Conveyors, & no differential speeds (“scuffing”) between the belt and the roller which reduces shell wear dramatically.

Weightthe RKM roller is OH&S friendly due to light mass.

TIR (Total Indicator Run out) & MIS (Mean Indicator Slope)compliant.

Balance QualityG16 to ISO1940.

Roller Material Build Uphas good properties against build up.

NoiseTypical Results.

AluminiumRoller samples