Features

?High luminous power.

?Red color.

?Bulk, available taped on reel.

?ESD-withstand voltage: up to 4KV

?The product itself will remain within RoHS compliant version.

Descriptions

?The series is designed for application required high luminous intensity.

?The phosphor filled in GaAsP/GaP chip to ideal white.

Device Selection Guide

LED Part No. | Chip Material | Lens Color |

R5113UC | GaAsP/GaP | Water clear |

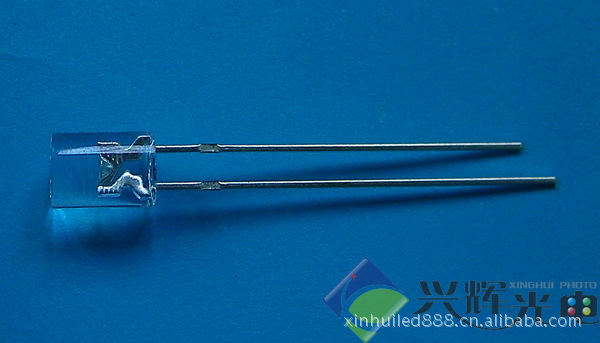

Package Dimensions

Absolute Maximum Ratings (Ta=25℃)

Parameter | Symbol | Rating | Unit |

Continuous Forward Current | IF | 30 | mA |

Peak Forward Current | IFP | 1 | A |

Reverse Voltage | VR | 5 | V |

Operating Temperature | Topr | -40 ~ +85 | ℃ |

Storage Temperature | Tstg | -40 ~ +85 | ℃ |

Soldering Temperature | Tsol | 260 | ℃ |

Power Dissipation at25℃Free Air Temperature | Pd | 80 | mW |

Zener Reverse Current | Iz | 100 | mA |

Notes:*1:IFPConditions--Pulse Width≦100μs and Duty≦1%.

*2:Soldering time≦5 seconds.

Electro-Optical Characteristics (Ta=25℃)

Parameter | Symbol | Condition | Min | Typ | Max | Unit |

Forward | VF | IF=20mA | 1.8 | -- | 2.3 | V |

Zener Voltage | Vz | Iz=5mA | 5.2 | -- | -- | V |

Reverse Current | IR | VR=5V | -- | -- | 5 | μA |

Luminous Intensity | Iv | IF=20mA | 4000 |

| 6000 | mcd |

View Angle | 2θ1/2 | IF=20mA | -- | 30 | -- | deg |

Peak Wavelength | λp | IF=20mA | 620 | -- | 625 | nm |

Packing Quantity Specification

1. 1000PCS/Bag

Notes

1. Lead Forming

a) During lead formation, the leads should be bent at a point at least 3mm from the base of the epoxy bulb.

b) Lead forming should be done before soldering.

c) Avoid stressing the LED package during leads forming. The stress to the base may damage the LED’s characteristics or it may break the LEDs.

d) Cut the LED leadframes at room temperature. Cutting the leadframes at high temperatures may cause failure of the LEDs.

e) When mounting the LEDs onto a PCB, the PCB holes must be aligned exactly with the lead position of the LED. If the LEDs are mounted with stress at the leads, it causes deterioration of the epoxy resin and this will degrade the LEDs.

2. Storage

a) The LEDs should be stored at 30°C or less and 70%RH or less after being shipped fromXinHuiand the storage life limits are 3 months. If the LEDs are stored for 3 months or more, they can be stored for a year in a sealed container with a nitrogen atmosphere and moisture absorbent material.

b) Please avoid rapid transitions in ambient temperature, especially, in high humidity environments where condensation can occur.

3. Soldering

a) Careful attention should be paid during soldering. When soldering, leave more then 3mm from solder joint to epoxy bulb, and soldering beyond the base of the tie bar is recommended.

b) Recommended soldering conditions:

Hand Soldering | DIP Soldering | ||

Temp. at tip of iron | 300℃Max. (60W Max.) | Preheat temp. | 100℃Max. (60 sec Max.) |

Soldering time | 3 sec Max. | Bath temp. & time | 260 Max., 5 sec Max |

Distance | 3mm Min.(From solder joint to epoxy bulb) | Distance | 3mm Min. (From solder joint to epoxy bulb) |

.

Remark

1. Above specification may be changed without notice. XingHui will reserve authority on material change for above specification.

2. When using this product, please observe the absolute maximum ratings and the instructions for using outlined in these specification sheets. XingHui assumes no responsibility for any damage resulting from use of the product which does not comply with the absolute maximum ratings and the instructions included in these specification sheets.

3. These specification sheets include materials protected under copyright of XingHui company. Please don’t reproduce or cause anyone to reproduce them without XingHui’s consent.