螺丝无铬表面处理 螺栓无铬表面处理 垫片无铬表面处理 冲压五金件无铬表面处理

螺丝环保表面处理 螺栓环保表面处理 垫片环保表面处理 冲压五金件环保表面处理

螺丝久美特 螺丝GEOMET 螺栓久美特 螺栓久美特 垫片久美特 垫片GEOMET 五金件GEOMET

The process of applying the GEOMET®coating requires the substrate to be clean bare steel. Sufficient cleanliness and coating weight is required for proper levels of adhesion and performance.

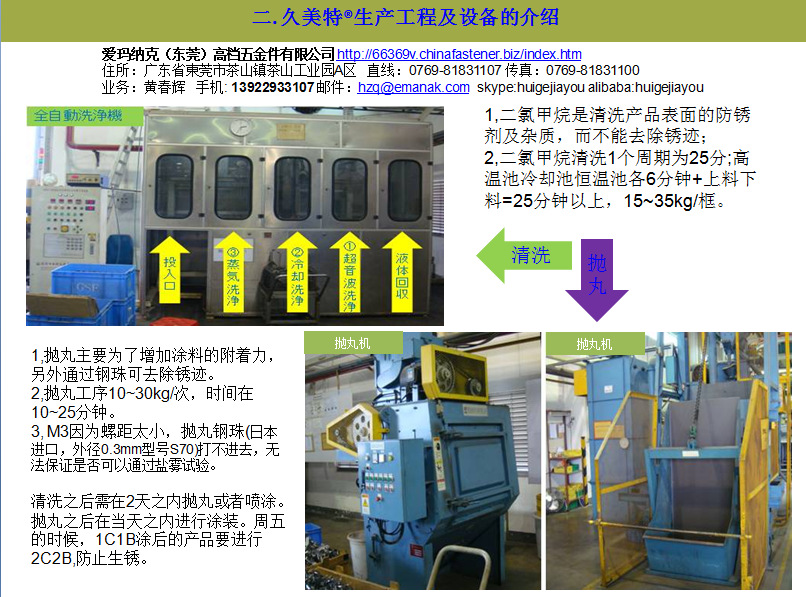

Cleaning Methods:

Alkaline Cleaning-In order to remove manufacturing oils or other contaminants, an alkaline wash by immersion or spray is used.

Mechanical Cleaning (Shot Blasting)-Mechanical cleaning uses steel grit, balls or glass beads to remove heat-treat scale and/or flash rust in addition to giving the part roughness to provide good adhesion.

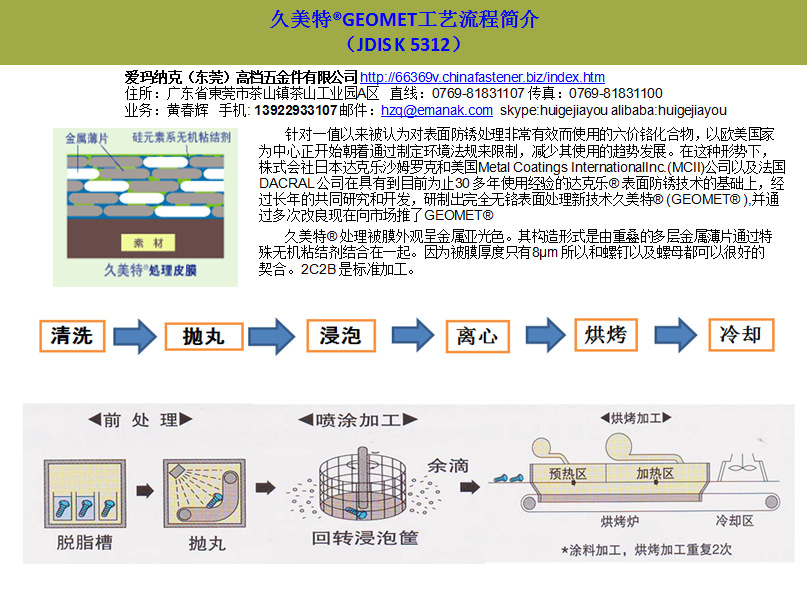

Application Methods:

Dip Spin-Small parts (fasteners, stampings, clips, springs, etc) are coated using the Dip Spin application method. Bulk parts are loaded into a basket, immersed into the GEOMET®coating, raised up and spun to remove the excess GEOMET®from the parts. Following coating, the parts are transferred onto a conveyor and proceed into a convection oven for curing.

* Parts coated using Dip Spin application method require two coats of the GEOMET®base coat.

Spray-Large parts (rotors, brackets, large fasteners, etc.) can be coated using the Spray application method. Parts are inpidually loaded onto a chain on edge or rack and continue past air or electrostatic spray nozzles that can be set to strict parameters to provide optimum coating weight on inpidual areas of the part. Following application of the GEOMET®coating, the parts proceed into a convection oven or induction-heating coil for curing.

* Parts coated using Spray application method require one coat of the GEOMET®base coat.

Dip-Drain Spin-Large parts (fuel filler tubes, stampings, large bolts, etc.) can be coated using the Dip-Drain Spin application method. Parts are inpidually loaded onto a rack, dipped into the GEOMET®coating, raised up and spun to remove the excess GEOMET®from the parts. Following coating, the parts proceed into a convection oven for curing.

* Parts coated using Dip-Drain Spin application method require one or two coats of the GEOMET®base coat.

Curing:

Pre-cure-Parts are subjected to 150-250° F (66-121° C) for 10 minutes to set the coating. Pre-cure is an essential element in the curing process to achieve proper adhesion and appearance.

Main Cure-Parts are transferred from pre-cure into the main cure to provide the final cure for the GEOMET®coating. In order to properly cure GEOMET®, a peak metal temperature of 575°-600° F (300-315° C) must be maintained for 15 minutes.