2、性能参数: |

LDZ3系列电磁失电制动器

LDZ3Series A Electromagnetic Power lost Brakes

一、简介(Applications)

LDZ3系列电磁失电制动器为通电脱离(释放),断电弹簧制动的摩擦式制动器。它主要与Y系列电动机配套成YEJ系列电磁制动三相异步电动机。广泛应用于冶金、建筑、化工、食品、机床、包装等机械中,及在断电时(防险)制动等场合。

这种制动器具有结构紧凑、安装方便、适应性广、噪声低、工作频率高、动作灵敏、制动可靠等优点,是一种理想的自动化执行元件。

TheLDZ3 A Electromagnetic Power lost Brakes is fricative braking device automatically set to working by a spring when a power-cut occurs, As a major accessory to our new YEJ series of three-phase motors, it`s widely applicable in machine tools and in machineries for metallurgy, construction, chemistry, food-prompt and accurate braking effect.

Because of its small size, light weight low noise and high reliability, it is widely accepeted as an ideal piece of automation equipment.

二、主要性能参数(Main Technical Data)

|

|

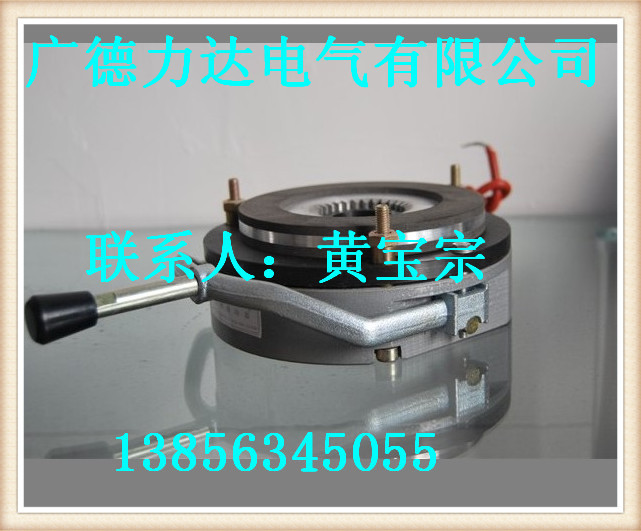

三、手动释放装置使用说明(Operation instructions of manual releasing device)

这是一种能软、硬释放的手动释放装置。当旋紧释放螺钉,通过钢球推动释放板,从而拉动衔铁解除制动,旋松螺钉,衔铁通过弹簧力复位,恢复制动状态,即为硬释放;软释放时须将释放螺钉换为手柄,向后端扳动手柄即可解除制动。(参见安装示意图)

It is can soft, hard releasing device. As fasten screw, it promote release board to through steel ball, pull armature, remove the brake. Loose screw, armature restore to the throne through spring strength, resume to brake state , this is hard releasing ; Soft must change to releasing screw handle, pull handle back end can remove the brake. (see the sketch map of install)

四、外形及安装尺寸(Overall and lnstallation Dimensions)

尺寸Size | d | KxM | D1 | D2 | D3 | D4 | b | h | L1 | L2 | L3 | H2 | H1 | L | δ |

LDZ3-05 | 14.8 | 3×M5 | 90 | 78 | 53 | 102 | 5 | 16.2 | 56 | 2 | 35 | 80 | 62 | 20 | 0.3 |

LDZ3-08 | 19.8 | 3×M5 | 105 | 92 | 60 | 118 | 6 | 21.6 | 66 | 3 | 43 | 85 | 70 | 20 | 0.3 |

LDZ3-15 | 24.8 | 3×M6 | 114 | 98 | 60 | 128 | 8 | 28.1 | 75 | 3 | 50 | 95 | 76 | 25 | 0.4 |

LDZ3-30 | 29.5 | 3×M6 | 133 | 118 | 80 | 147 | 8 | 32.8 | 75 | 3 | 51 | 106 | 88 | 30 | 0.4 |

LDZ3-40 | 29.5 | 3×M8 | 150 | 131 | 90 | 167 | 8 | 32.8 | 78 | 3 | 51 | 118 | 98 | 30 | 0.5 |

LDZ3-80 | 39.5 | 3×M8 | 170 | 151 | 104 | 188 | 12 | 42.8 | 91 | 3 | 62 | 130 | 110 | 30 | 0.5 |

LDZ3-150 | 44.5 | 4×M10 | 202 | 181 | 120 | 222 | 12 | 47.8 | 95 | 3.5 | 68 | 150 | 128 | 35 | 0.6 |

五、安装(Installation)

安装注意事项 Warning

●摩擦片及衔铁表面不得有油污,必须保持清洁;

Friction disc and armature surface should be kept clean and free of grease.

●安装时必须保证气隙“δ”;

When fixing, the airgap "δ" should be kept to the specified value.

●齿轮套不得有轴向窜动。

The gear hub are not allowed to move along axially.

●安装后必须旋出空心螺栓锁紧在电机后端盖或法兰