供应创维丞桥架生产数控桥架生产线

张家港市创维丞机械有限公司

中国 无锡

产品属性

图文详情

品牌推荐

额定电压

380V

型号

桥架生产

品牌

创维丞

型式

梯形式桥架

加工定制

是

材质

镀锌桥架

类型

高强轻型桥架

外形尺寸

10000mm

重量

8000Kg

电缆桥架自动化生产线

电缆桥架自动化生产线配套设备技术条件(伺服)

Automatic production line of cable rack (servo)

1 成型工艺 forming processing

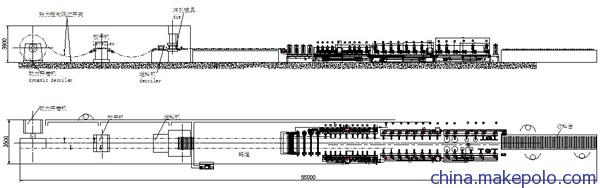

开卷→整平→夹送、冲孔→成型→定尺、切断→收料

Uncoiler-flatting-clampZ&punching-forming-positioning&cutting-collection

2 设备性能 equipment capacity

可根据生产需要轧制个带钢宽度100mm≤§≤860mm多种规格的电缆桥架及其他结构产品。

The production line can produce many types of cable rack and other machinery products according to producing requirement.(steel coil width 100mm≤§≤860mm)

在线冲孔时生产速度:2.5~5米/分钟。

Line speed:2.5-5M/min

成型设备连续成型速度时:10~15米/分钟。

Continuous forming speed:10-15M/min

板材料厚:1~2mm。Steel thickness:1-2mm

材质要求:Q235冷轧板。Material :Q235

生产线分自动和手动两种操作方式,可实现联动和分段运转作业。

The production line pide into two operations: automatic &handle. It can work with linkage and subsection .

全套设备由开卷机、ML-900整平机、JF21-200冲床、冲模、 伺服送料装置、导向机架、成型主机、跟踪切断、定尺装置、收料台和电器控制等部件组成。

The whole equipment consists of uncoiler,ML-900 flatting device,JF-200punching,punching mould, servo-feeding device, guider, forming machine, cutting device, positioning device, collection table and electrical control. etc

4 各部件的主要技术参数 main part technical data

4.1 动力开卷机 uncoiler

材料宽度:1200mm steel width:860mm

材料重量:10000kg steel weight:5000kg

材料内径:460~510mm inner dia:460-510mm

材料外径:1200mm outer dia:1200mm

驱动功率:电机与减速机一体化,5.5KW变频电机

Driver power: frequency conversion and reducer, 5.5KWfrequcncy conversion

结构型式:悬臂内涨支撑式,尾部手动操作,气动压料臂。

Structure type: operation by hand,

4.2 整平机 flatting device

工作辊数:11辊,上4下5,另外2辊为夹送辊

Rollers:11 rollers,up4/down5.other rollers for clamping .

校平工作范围:料厚1~2mm,板宽100~860mm

Work range: thickness 1-2mm,width100-860mm

驱动功率:5.5kw变频电机 power:5.5kwfrequency conversion

减速机型号:ZQ250 type reducer

校平速度:3~10米/分钟 flatting speed:3-10M/min

附带上下加强托轮1对 parenthesis one pair of wheel

4.3 连续冲孔模具 continuous punching mould

模具数量: 6套

QTY: 6 sets.

冲模材质:Cr12 淬火

Punching material:Cr12 Quenching

4.4 伺服送料装置 servo-feeding device

多段式送料,内存十组记忆功能excessive section type feeding, ten memory function

人机界面数控系统CNC control

采用三菱伺服马达MITSUBISHI SERVO-MOTOR

4.5 托料架(用于缓冲段)feeding table (amortize)

滚筒式,两端有轴承支撑,数量:3套,用于托料和储料下限位。

Rollers type both sides have been supported by axletreesQTY:3 sets.

4.6 导向机架 guider rack

由一对水平辊及二对立式导向辊组成,共计2套。

It consists of one set of leveling rollers and two pairs of standing rollers. total 2sets

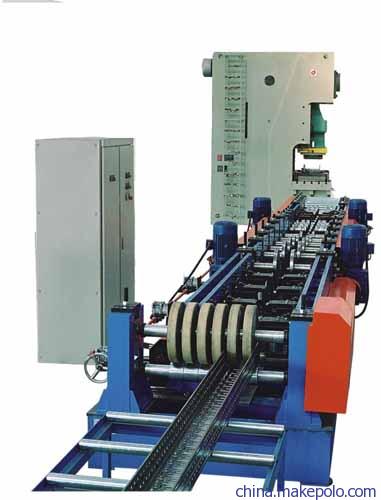

4.7 成型主机 forming machine

机器型号:GY160型(宽幅)

Type :GY160

机架结构:龙门式牌坊架 frame: dragon type

成型道次:16道(辊)forming frame:16 sets

成型品种:桥架、盖板forming breed: frame cover board

最大进料宽度:860mm max feeding width:860mm.

最大材料厚度:≤2.0mm max material thickness:≤2.0mm

成型宽度:100~400mm forming width:100-400mm

成型高度:50~100mm forming height:50-100mm

轧辊轴轴径:¢85 mm the diameter of axis shaft :¢85 mm

轧辊模具材质:Gcr15,淬火处理,HRC58-62°

Roller material mould:Gcr15,quenching ,hardness HRC58-62°

传动型式:30kw 变频电机,ZQ500型主减速机,独立分配齿轮箱。

Drive type: 30KWfrequency conversion ,ZQ500type reducer, independence distribute gear box.

4.8 液压切断 hydraulic cutting

液压泵站:5.5kw hydraulic pump station:5.5kw

刀片切断,刀片材质Cr15,淬火处理。

Blade cutting, blade materialCr15,quenching

刀片数量:7件

Blade QTY:7

电缆桥架自动化生产线配套设备技术条件(伺服)

Automatic production line of cable rack (servo)

1 成型工艺 forming processing

开卷→整平→夹送、冲孔→成型→定尺、切断→收料

Uncoiler-flatting-clampZ&punching-forming-positioning&cutting-collection

2 设备性能 equipment capacity

可根据生产需要轧制个带钢宽度100mm≤§≤860mm多种规格的电缆桥架及其他结构产品。

The production line can produce many types of cable rack and other machinery products according to producing requirement.(steel coil width 100mm≤§≤860mm)

在线冲孔时生产速度:2.5~5米/分钟。

Line speed:2.5-5M/min

成型设备连续成型速度时:10~15米/分钟。

Continuous forming speed:10-15M/min

板材料厚:1~2mm。Steel thickness:1-2mm

材质要求:Q235冷轧板。Material :Q235

生产线分自动和手动两种操作方式,可实现联动和分段运转作业。

The production line pide into two operations: automatic &handle. It can work with linkage and subsection .

全套设备由开卷机、ML-900整平机、JF21-200冲床、冲模、 伺服送料装置、导向机架、成型主机、跟踪切断、定尺装置、收料台和电器控制等部件组成。

The whole equipment consists of uncoiler,ML-900 flatting device,JF-200punching,punching mould, servo-feeding device, guider, forming machine, cutting device, positioning device, collection table and electrical control. etc

4 各部件的主要技术参数 main part technical data

4.1 动力开卷机 uncoiler

材料宽度:1200mm steel width:860mm

材料重量:10000kg steel weight:5000kg

材料内径:460~510mm inner dia:460-510mm

材料外径:1200mm outer dia:1200mm

驱动功率:电机与减速机一体化,5.5KW变频电机

Driver power: frequency conversion and reducer, 5.5KWfrequcncy conversion

结构型式:悬臂内涨支撑式,尾部手动操作,气动压料臂。

Structure type: operation by hand,

4.2 整平机 flatting device

工作辊数:11辊,上4下5,另外2辊为夹送辊

Rollers:11 rollers,up4/down5.other rollers for clamping .

校平工作范围:料厚1~2mm,板宽100~860mm

Work range: thickness 1-2mm,width100-860mm

驱动功率:5.5kw变频电机 power:5.5kwfrequency conversion

减速机型号:ZQ250 type reducer

校平速度:3~10米/分钟 flatting speed:3-10M/min

附带上下加强托轮1对 parenthesis one pair of wheel

4.3 连续冲孔模具 continuous punching mould

模具数量: 6套

QTY: 6 sets.

冲模材质:Cr12 淬火

Punching material:Cr12 Quenching

4.4 伺服送料装置 servo-feeding device

多段式送料,内存十组记忆功能excessive section type feeding, ten memory function

人机界面数控系统CNC control

采用三菱伺服马达MITSUBISHI SERVO-MOTOR

4.5 托料架(用于缓冲段)feeding table (amortize)

滚筒式,两端有轴承支撑,数量:3套,用于托料和储料下限位。

Rollers type both sides have been supported by axletreesQTY:3 sets.

4.6 导向机架 guider rack

由一对水平辊及二对立式导向辊组成,共计2套。

It consists of one set of leveling rollers and two pairs of standing rollers. total 2sets

4.7 成型主机 forming machine

机器型号:GY160型(宽幅)

Type :GY160

机架结构:龙门式牌坊架 frame: dragon type

成型道次:16道(辊)forming frame:16 sets

成型品种:桥架、盖板forming breed: frame cover board

最大进料宽度:860mm max feeding width:860mm.

最大材料厚度:≤2.0mm max material thickness:≤2.0mm

成型宽度:100~400mm forming width:100-400mm

成型高度:50~100mm forming height:50-100mm

轧辊轴轴径:¢85 mm the diameter of axis shaft :¢85 mm

轧辊模具材质:Gcr15,淬火处理,HRC58-62°

Roller material mould:Gcr15,quenching ,hardness HRC58-62°

传动型式:30kw 变频电机,ZQ500型主减速机,独立分配齿轮箱。

Drive type: 30KWfrequency conversion ,ZQ500type reducer, independence distribute gear box.

4.8 液压切断 hydraulic cutting

液压泵站:5.5kw hydraulic pump station:5.5kw

刀片切断,刀片材质Cr15,淬火处理。

Blade cutting, blade materialCr15,quenching

刀片数量:7件

Blade QTY:7