NOW AVAILABLE: SHAFTDESIGNER - THE INNOVATIVE SOFTWARE FOR PROPULSION TRAIN CALCULATIONS

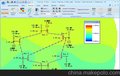

Welcome to ShaftDesigner, the innovative Computer Aided Engineering (CAE) software which is a great help for anyone involved in the design, installation, maintenance and repair of propulsion shafts. A practical user interface with easy modelling features helps create a realistic 3D representation of the shaft line, while detailed but orderly data reports provide all the information needed by the user, creating optimally functioning shafts.

Background

ShaftDesigner was developed by Dr. Yuriy Batrak of Intellectual Maritime Technologies (IMT) in the Ukraine for Machine Support B.V in the Netherlands as part of their service pision in shaft alignment. It was created as a bridge between IMT's theoretical expertise and Machine Support's practical experience in the field of shaft alignment and mounting. Thanks to the software's capabilities to perform reversed calculations, the theory and practical findings could be cross-validated, guaranteeing accurate results. In the development of ShaftDesigner there was also a close cooperation with classification societies and leading OEMs of various components of the propulsion train, in order to meet their needs.

ShaftDesigner's innovations

The rationale of ShaftDesigner was that further development was needed in the field of alignment software. Three main problems in current software were identified. The first is the lack of a single shaft model to perform all types of shaft related calculations. Up to now separate software with different data models for alignment and for each type of vibration has been used. The second problem is the inability to analyse different operating conditions from ballast to laden, cold and warm engine and different states from uncoupled shaft, to fully assembled propulsion trains. The user has always been forced to manage and maintain many files to achieve solutions in different states. Finally there was a substantial disparity between modern knowledge in the propulsion train domain and the capabilities of software in use.

Design phase

An accurate representation of all components of the propulsion train, including engines, gearboxes, bearings and propellers, is created using details about each element. Because of the easy drag and drop function of ShaftDesigner, all the propulsion train components are relatively fast to place, to speed up shaft line modelling. From an engineering point of view ShaftDesigner provides a useful tool to explore offsets to optimize the position of all propulsion train components based on acceptance criteria set by the user. This is done in order to, at an early stage, guarantee a good bearing load distribution and thus safe operation of the shaft line. Because ShaftDesigner can identify this issue in the ship's design phase, possible time-consuming and costly (re-)alignment problems can be avoided. Also, at this early stage, with the various vibration modules, it is possible to calculate if a certain lay-out has the potential to create harmful vibrations and estimate possible alterations which could be necessary.

Benefits

Problem: I am looking for software that can model more than just shaft trains.

Solution: ShaftDesigner can model entire propulsion trains including propellers, engines, gearboxes, flywheels, generators and more.

Problem: My vessel is suffering from shaft alignment problems.

Solution: Creating a ShaftDesigner model is a good starting point to find the source of the problem. ShaftDesigner is ideal for this as the software provides the opportunity to find the problem without having to take the vessel out of operation, which saves a lot of down time.

Problem: My vessel regularly has bearing failures.

Solution: Often, bearing failures are caused by a wrongly aligned shaft line. ShaftDesigner can easily optimize the alignment for the entire shaft train, resulting in a much smaller chance of unexpected bearing failures.

Problem: Does ShaftDesigner support condition monitoring?

Solution: The current version of ShaftDesigner does currently not support condition monitoring. However, because ShaftDesigner provides information about the wear of bearings it is easier to anticipate which bearing will wear fastest.

Problem: There are annoying vibrations on board my vessel.

Solution: ShaftDesigner's vibration modules are capable of calculating where these vibrations are coming from. Action can then be taken to get rid of these vibrations.

Problem: Can I know in advance if a certain propulsion train will vibrate.

Solution: With ShaftDesigner's vibration modules it is possible to in the design phase of a ship calculate if there is a chance of harmful vibrations. This can save a lot of time and effort if alterations are needed after the vessel's construction.

Problem: Is ShaftDesigner also useful when my vessel has sustained hull damage?

Solution: Hull deflections are one of the inputs possible in ShaftDesigner. Using this feature it is possible to check if the alignment of the propulsion train is still valid after the damage has been sustained.