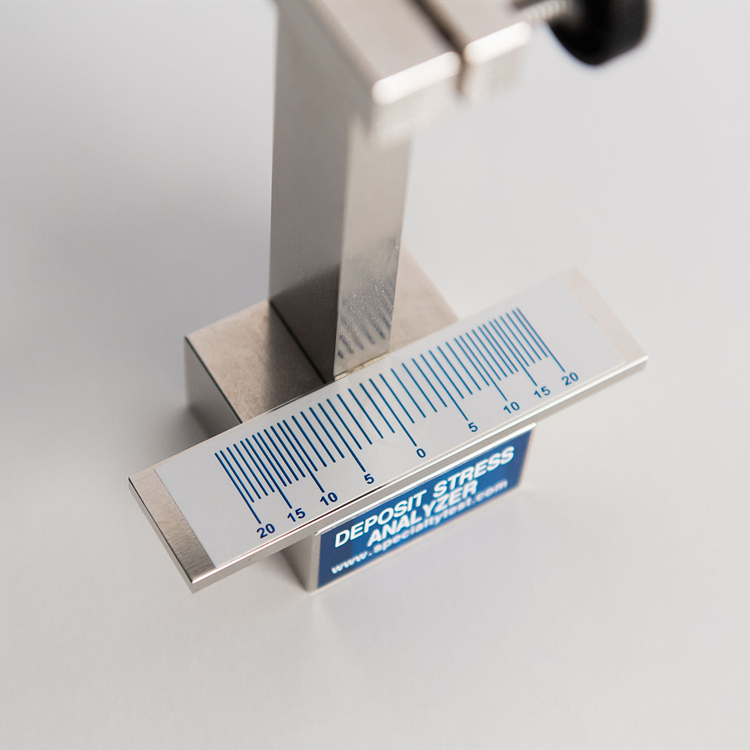

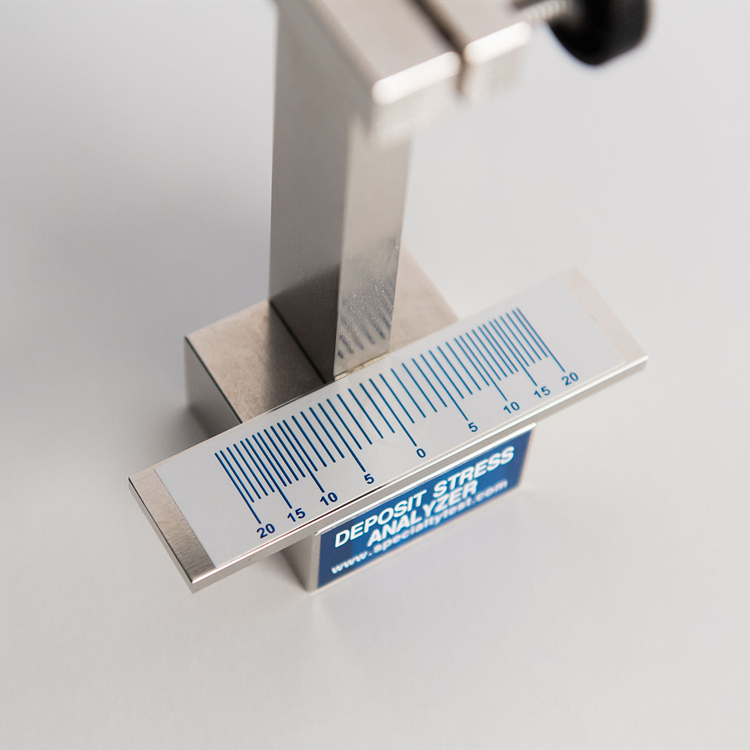

美国进口specialtytest品牌683型镀层内应力测试仪

美国进口specialtytest品牌683型镀层内应力测试仪 |

薄片阴极弯曲法

薄片阴极弯曲法是一种经典的内应力测量方法。其基本形式是:采用一块狭长的金属薄片作阴极,背向阳极的一面绝缘;电镀时一端用夹具固定另一端可以自由活动;电镀后,镀层中产生的内应力会迫使薄片阴极弯曲。其内应力计算公式为:

式中:σ为镀层内应力,Pa;E为薄片阴极的弹性模量,Pa;t为薄片阴极的厚度,mm;R为薄片阴极的弯曲半径,mm;d为镀层的厚度,mm。

薄片阴极弯曲法的主要缺点是:(1)试样背面的绝缘层往往会污染电镀溶液,同时影响试样的刚性,这种影响难以在内应力计算中加以考虑和修正;(2)绝缘不完全或在电镀过程中产生脱落也会改变阴极的弯曲程度;(3)窄条试样变弯以后,改变了它与阳极的距离,也就改变了阴极上的电流分布。

取一条长l20mm、宽8mm的薄铜片,铜片的厚度不要超过0.2mm。将这种铜片经去油和酸蚀后干燥,然后在铜片的一面均匀地涂上一层聚氯乙烯清漆,使这个面不能镀上镀层。然后在要测试的镀液内进行电镀。电镀时让试片竖直在镀槽中,上端固定,受镀面向着阳极。随着镀层的增长,试片会发生弯曲,如果镀层向阳极方向弯瞌,也就是向有镀层的一面内弯,这时镀层有压应力。如果试片向着没有镀层的一面弯曲,则镀层有张应力。通过添加剂和温度、pH值等工艺条件的调整,可以使镀层应力得到调整,当两种应力相抵而为零时,镀出的试片不会发生弯曲。弯曲的幅度越大,说明应力越大。

推荐仪器:美国进口Deposit Stress Analyzer,美国进口specialtytest品牌683型镀层内应力测试仪,详情可咨询我们!

The Deposit Stress Analyzer is a unique, reliable, urate and economical method for testing the internal deposit stress exhibited in thin metallic coatings such as those deposited by electrolytic and electroless plating processes, electrocoated deposits, polymer-based coatings and ceramic coatings.

Testing using the Deposit Stress Analyzer is simple and requires a low capital investment. Test strips can be coated along with work being processed, or testing can be plished by coating the test strips separately in a laboratory or bench set-up with the deposit or coating being evaluated.

Calculation of the internal deposit stress in pounds per square inch, whether tensile or compressive,can be easily calculated.

Product Features

ECONOMICAL TO USE

RAPID DETERMINATIONS

URATE RESULTS

DISCARDABLE TEST STRIPS

SMALL SAMPLE SURFACE AREA

SMALL ELECTROLYTE VOLUME

NO CALIBRATION