WNS卧式全自动燃油/气蒸汽锅炉Being horizontal automatic fuel oil/gas steam boiler

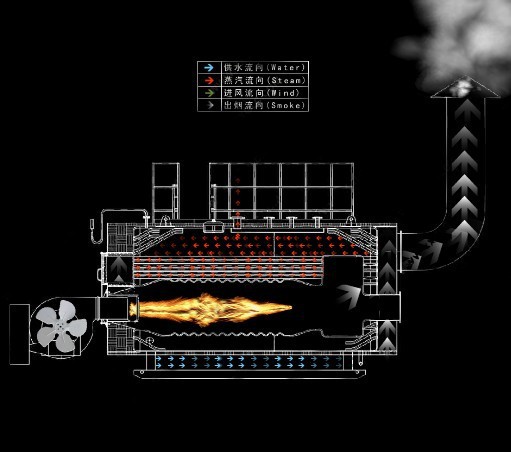

WNS型燃气锅炉为卧式快装内燃三回程火管锅炉.采用偏置炉胆湿背式结构,高温烟气依次冲刷第二及第三回程烟管,然后由后烟室经烟囱排入大气.锅炉装有活动的前后烟箱盖,使锅炉检修方便.锅炉配置技术性能良好燃烧器,采用了燃烧自动比例调节,给水自动调节,程序启停,全自动运行等先进技术,并具有高低水位报警和极低水位、超高汽压、熄火等自动保护功能.该型锅炉具有结构紧凑、安全可靠、操作简便、安装迅速、污染少、噪音低、效率高等特点.

Being type gas boiler combustion for horizontal fast three return fire tube boiler. Using offset furnace wet back structure, high temperature gas scour the second and third in turn return pipe, and then the smoke chamber through the chimney into the atmosphere. The boiler is equipped with smoke box cover before and after the activity, make boiler maintenance convenient. Boiler burner configuration technology performance is good, the combustion proportional control automatically, automatic feed water regulation, procedure rev. Stop, fully automatic operation and other advanced technology, and have high and low water level alarm and low water level, steam pressure, flameout automatic protection function etc. The type boiler has a compact structure, safe and reliable, simple operation, rapid installation, low pollution, low noise, high efficiency, etc.

主要特点:

1、 整体结构合理、紧凑、属锅炉岛型,符合 快装出厂条件 .本产品出厂时由三大部分组成;锅炉主机、烟囱及管路系统,其中主机和烟囱部分已在厂内制造完毕,主机所配套的管路阀门、仪表已随机装妥,运至现场将主机和烟囱组装即可.现场接通气源、电源、水管路即可试车.大大缩短了安装周期,且可保证产品质量.2 设计性能先进.该锅炉主机属整体结构,燃烧器装配在前烟箱盖上,本体主要布置受热面和燃烧室部分.具有结构合理、紧凑,钢材耗量低,炉胆采用偏置波形炉胆, 保温层选用新型轻质隔热保温材料,外包装采用彩色薄板,外形包装为长方体,使锅炉性能、重量、结构尺寸、外观造型与国内同容量产品相比具有明显的先进性和美观感.该锅炉给水设备配置在锅炉右侧的锅炉底座上使之与主机为一体,不须另做基础.3、水循环简单,受压部件结构合理,在保证水质的情下,可以安全运行.4、配套辅机齐全,综合技术性能先进

Main features:

1, the overall structure is reasonable, compact, belongs to the boiler island, comply with the requirements for fast loading factory. This product factory is composed of three parts; Boiler host, chimney and pipeline system, in which the host and the chimney part has been made in our factory finished, pipe valves, instrument host form a complete set of the random that had been completed, shipped to the site will be the host and chimney assembly. The scene test. Just by turning on the air water, electrical power, greatly shorten installation period, and can guarantee the quality of the product. 2 design performance is advanced. The host belongs to the whole structure, boiler burner assembly before smoke box lid, the main arrangement of heating surface and the combustion chamber. The features of reasonable structure, compact, low steel consumption, furnace with offset waveform furnace, thermal insulation layer to choose new lightweight heat insulation heat preservation material, outer packing USES color sheet, packing shape of cuboid, the boiler performance, weight, structure size and appearance model is compared with domestic products with capacity has obvious advancement and the look and feel. The boiler feed water equipment in the boiler on the right side of the base with the host as a whole, not the other do. 3, the water cycle is simple, pressure retaining structure is reasonable, in the guarantee quality, under the situation of safe operation. 4, supporting auxiliary complete, comprehensive technical performance is advanced

【WNS燃油燃气锅炉配置清单】

银宇锅炉 | WNS型燃油锅炉配置清单 | 第1页 | |||

共1页 | |||||

序号 | 图号或型号 | 产品名称 | 产地 | 数量 | 备注 |

一 | 锅炉主机 | ||||

1 | YXQ6530-0-0 | 锅炉主机 | 本 厂 | 1 | 终身保修 |

二 | 阀门仪表及安全附件 | ||||

1 | Y-150 | 压力表0~2 5MPa 2 5级 | 郑州 | 2 | 一年更换 |

2 | X14W-1 6T | 压力表三通旋塞 | 郑州 | 2 | 一年更换 |

3 | GGT12 01 | 压力表存水弯管 | 本 厂 | 1 | 终身保修 |

4 | A48H-1 6C | 全启弹簧安全阀 PN1 6 DN80 | 郑州 | 2 | 一年更换 |

5 | J44H-1 6C | 主汽阀 PN1 6 DN80 | 郑州 | 1 | 一年更换 |

6 | J44H-1 6C | 副汽阀 PN1 6 DN32 | 郑州 | 1 | 一年更换 |

7 | J4H-1 6C | 截止阀 PN1 6 DN32 | 郑州 | 1 | 一年更换 |

8 | J41H-1 6C | 截止阀 PN1 6 DN32 | 郑州 | 2 | 一年更换 |

9 | J41H-1 6C | 止回阀 PN1 6 DN32 | 郑州 | 1 | 一年更换 |

10 | X49X-25-350 | 水位表 PN1 6 DN25 L=350 | 郑州 | 2 | 一年更换 |

11 | P48H-1 6Q | 排污阀 PN1 6 DN50 | 郑州 | 2 | 一年更换 |

12 | YCW6223-2-0 | 锅筒排污弯管φ57×3 5 | 郑州 | 1 | 一年更换 |

13 | J41H-1 6C | 球阀 PN1 6 DN25 | 郑州 | 4 | 一年更换 |

14 | SZB-20 | 电极式水位控制器PN1 6 DN25 | 南 京 | 2 | 一年更换 |

15 | YMK-50-C | 压力控制器 | 南 京 | 3 | 一年更换 |

16 | WZB-210 | 测温热电偶 | 南 京 | 1 | 一年更换 |

17 | GB6780-86 | 螺栓 M12×55 |

| 72 | 一年更换 |

18 | GB6170-86 | 螺母 M12 |

| 72 | 一年更换 |

19 | YX2010BS | 易损配件 | 河 北 | 6 | 五年备用 |

20 | YX2010GJ | 安全连锁保护 | 南 京 | 1 | 终身保修 |

|

|

|

|

|

|

三 | 配套辅机 | ||||

1 | YXQ6020-0-0 | 烟囱 | 本 厂 | 1 | 终身保修 |

2 | YXQ6020-0-0 | 烟囱弯头 | 本 厂 | 1 | 终身保修 |

3 | YXQ6020-0-0 | 分汽缸 | 本 厂 | 1 | 终身保修 |

4 | BT180(BGN200P) | 燃烧机 | 意大利百得 | 1 | 一年更换 |

5 | XD-1 | 全自动电脑控制器 | 南 京 | 1 | 一年更换 |

6 |

| 全自动水处理 | 美 国 | 1 | 一年更换 |

7 |

| 水 箱 | 本 厂 | 1 | 终身保修 |

8 | 1(1/2)GC5×7 | 给水泵 电机功率:7 5KW | 郑 州 | 1 | 一年更换 |

备 注 | |||||

1、产品报价内应包含以上所有锅炉辅机配件 | |||||

2、以上锅炉配置可根据客户特殊要求更改,须在我公司工程师指导下进行。 | |||||

3、我公司锅炉辅机配件不断追求最高配置,如有变动不另行通知,以签订合同发货清单为准。 | |||||

【WNS燃油燃气系列锅炉技术参数】

型号 | WNS0.5-0.4(0.8) | WNS0.75-0.4(0.8) | WNS1-0.8(1.0) | WNS1.5-1.0 | WNS2-1.0 | WNS3-1.25 | |

项目 | 参数 | ||||||

额定热功率(MW) | 0.5 | 0.75 | 1 | 1.5 | 2 | 3 | |

额定工作压力(MPa) | 0.4(0.8) | 0.4(0.8) | 0.8(1.0) | 1.0 | 1.0 | 1.25 | |

出/回水温度(℃) | 152(175) | 175(184) | 184 | 184 | 194 | ||

设计效率(%) | 85%-92% | ||||||

水容积(m3) | 1.2 | 1.56 | 2.10 | 2.7 | 2.7 | 5.9 | |

满水重量(t) | 4.48(5) | 5.76(6.2) | 6.48(7.1) | 8(8.4) | 8(8.4) | 16(16.8) | |

耗电功率(KW) | 3.6 | 3.6 | 5.9 | 15.8 | 17.7 | 19.7 | |

电源(V) | 380 | ||||||

适用燃料 | 轻油、天然气、重油、城市煤气、石油液化气 | ||||||

计算耗量: | 34 | 51 | 65 | 102 | 136 | 204 | |

长×宽×高(mm) | 2650×1600 | 2650×1600 | 3650×1800 | 5200×2300 | 5200×2300 | 5570×3200 | |

安 | 进/出口阀口径(mm) | 50 | 65 | 65 | 65 | 65 | 100 |

排污阀口径 | 40 | 40 | 40 | 40 | 40 | 40 | |

安全阀口径 | 40 | 2×40 | 2×40 | 2×50 | 2×50 | 2×65 | |

烟囱口径ф | 250 | 300 | 320 | 360 | 360 | 360 | |

型号 | WNS4-1.25 | WNS5 -1.25 | WNS6-1.25 | WNS8 -1.25 | WNS10 -1.25 | WNS15 -1.25 | WNS20 -1.25 | |

项目 | 参数 | |||||||

额定热功率(MW) | 4 | 5 | 6 | 8 | 10 | 15 | 20 | |

额定工作压力(MPa) | 1.25(1.6) | |||||||

出水/回水温度(℃) | 194(204) | |||||||

锅炉设计效率(%) | 85%-92% | |||||||

水容积(m3) | 7.14 | 10 | 10.2 | 13.9 | 16.7 | 30 | 30 | |

满水重量(t) | 22(23.5) | 24.7(26) | 25.5(26.5) | 32.5(34.5) | 38(42) | 74(78) | 78(82) | |

耗电功率(KW) | 22.2 | 34.4 | 34.4 | 36 | 36 | 72 | 72 | |

电源(V) | 380 | |||||||

适用燃料 | 轻油、天然气、重油、城市煤气、石油液化气 | |||||||

计算耗量: | 272 | 241 | 382 | 482 | 603 | 904 | 1206 | |

长×宽×高(mm) | 5600×3300 | 6020×3300 | 7200×3300 | 7300×3300 | 7400×3300 | 8100×4200 | 8500×4500 | |

安 | 进/出口阀口径(mm) | 100 | 125 | 125 | 150 | 150 | 200 | 200 |

排污阀口径 | 2×40 | 2×40 | 2×40 | 2×40 | 2×40 | 2×40 | 40 | |

安全阀口径 | 2×50 | 50×80 | 50×80 | 2×80 | 2×80 | 2×80 | 2×100 | |

烟囱口径ф | 530 | 530 | 530 | 680 | 380 | 1000 | 1200 | |