WIKA PGT63HP.100 PGT63HP.160

不锈钢安全型电接点膜盒压力表 Capsule pressure gauge with

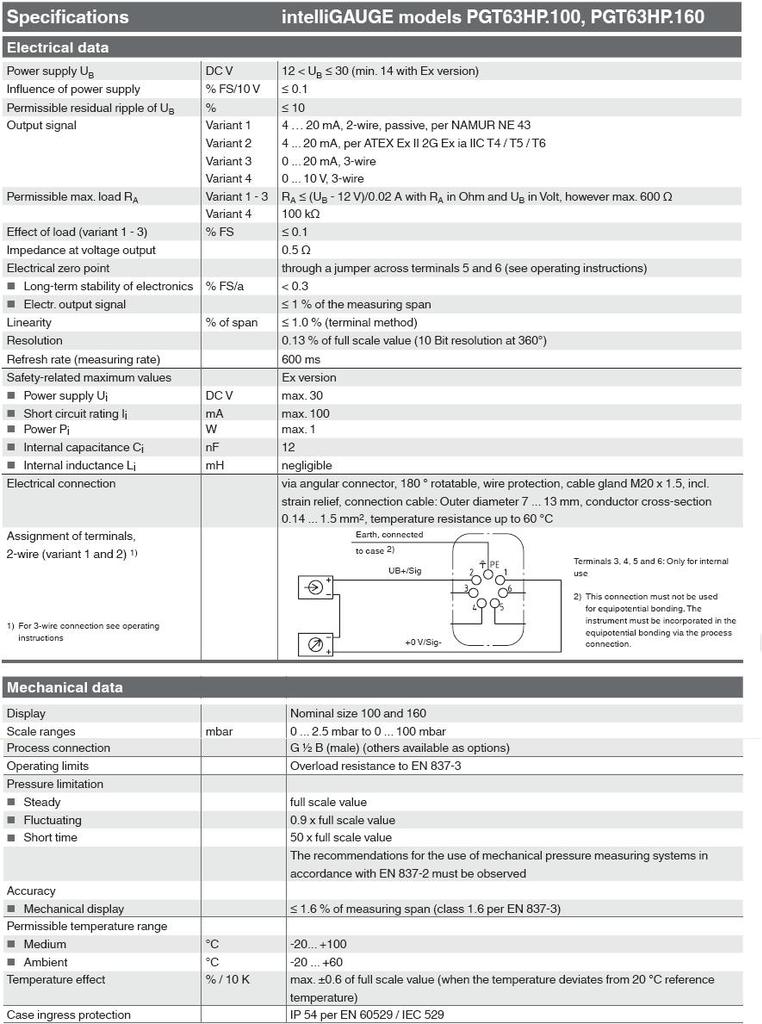

electrical output signal

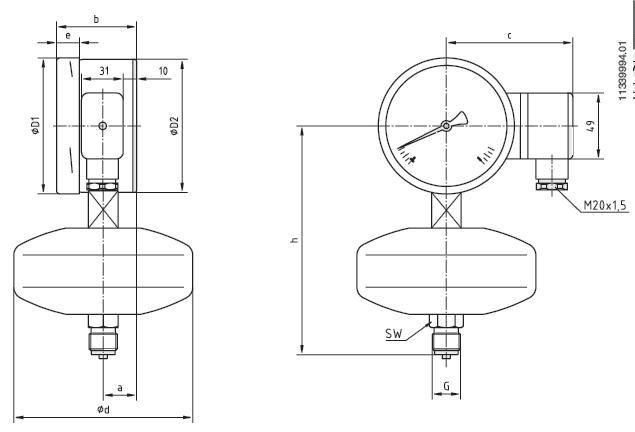

Applications Description Standard version Stainless steel 1.4571 Options Approvals Certificates 2) The capsule element (2)

is pressurised from outside and moves in strokes (deflection) Dimensions in

mm Ordering

information Model / Nominal size / Scale range / Output signal /

Options 欢迎致电咨询订购WIKA PGT63HP.100 PGT63HP.160

不锈钢安全型电接点膜盒压力表 电话:010-51669912 56291930 15910733293 传真:010-51669912 QQ:823377546 1491421115 2636968574 邮箱:sales@zoriver.cn 公司官网:

Stainless steel, safety version, high overpressure

safety

Models PGT63HP.100 and PGT63HP.160

Pressure

measurement at very low pressures

Acquisition and display of process

values for the control room, 4 ... 20 mA, 0 ... 20 mA or 0 ... 10 V

For

gaseous, aggressive media, also in aggressive

ambience

Easy-to-read,

local analogue display with Ø 100 mm or Ø 160 mm, no external power supply

needed

Special

features

"Plug-and-play" with no configuration

necessary

High overpressure safety up to 50 x full scale value

Measuring chamber protected against unauthorised intervention

Minimal

influence on function and measuring error from pressure medium

contamination

At any

point where very low pressures have to be indicated locally, and, at the same

time, a signal is wanted to be transmitted to a central controller or remote

control room, the model PGT63HP intelliGAUGE (US Patent No. 8,030,990)

can be

used.

Even if the power supply is completely lost, the process pressure

can be read securely. The rugged design of the capsule measuring system has an

overpressure safety of up to 50 times the full-scale value.

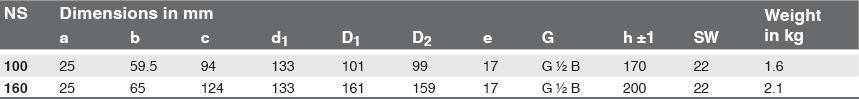

An electronic

angle encoder, proven in safety-critical automotive applications, determines the

position of the pointer shaft - it is a non-contact sensor and therefore

completely free from wear and friction.

From this, the

pressure-proportional electrical output signal, e.g. 4 ... 20 mA, is produced.

The electronic zero point can also be set manually.

The electronic WIKA

transmitter, integrated into the high-quality mechanical pressure gauge,

combines the advantages of electrical signal transmission with the

advantages

of a local mechanical display.

Capsule pressure gauge model PGT63HP.100

Nominal size in mm

100 and 160

Accuracy class

1.6

Scale ranges

0 … 2.5 to 0 … 100

mbar

or all other equivalent vacuum or combined pressure and

vacuum ranges

Process connection (wetted)

Stainless steel 1.4571

Lower mount (LM)

G ½ B (male), 22 mm

flats

Pressure element (wetted)

Stainless steel 1.4571

Measuring chamber

(wetted)

Sealing (wetted)

PTFE

Movement

Brass

Dial

Aluminium, white, black

lettering

Pointer

Adjustable pointer,

aluminium, black

Zero adjustment

By means of

adjustable pointer (adjustment appliance with gauges with switch

contacts)

Electronic: see operating instructions

Case

Stainless steel, ingress

protection IP 54

Window

Laminated safety

glass

Bezel ring

Cam ring (bayonet

type), stainless steel

Other process connection

Sealings (model 910.17, see data sheet AC 09.08)

Mounting bracket for

wall or pipe mounting (data sheet AC 09.07)

Panel or surface mounting

flange (observe measuring chamber!)

Higher overpressure safety 1)

Switch contacts (data sheet AC 08.01)

1) After feasibility

test

CE

conformity

EMC directive

2004/108/EC, EN 61326

emission (group 1, class B) and interference immunity (industrial

application)

ATEX directive

2)

94/9/EC, II 2 G Ex ia IIC

GOST-R, import certificate, Russia

CRN, safety (e.g. electr. safety, overpressure, ...),

Canada

2.2 test report per

EN 10204 (e.g. state-of-the-art manufacturing, material proof, indication

accuracy)

3.1 inspection certificate per EN 10204 (e.g. material proof

wetted parts metal component, indication accuracy)

2)

Option

Approvals and certificates, see website

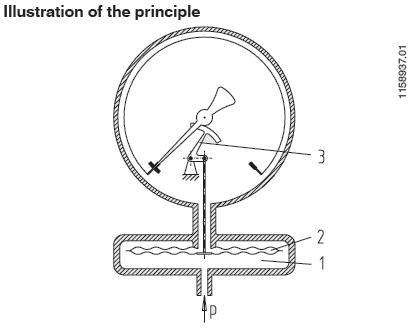

Design and operating

principle

Pressure-sealed measuring

chamber (1) with capsule measuring element

The

deflection is transmitted to the movement (3) and indicated

The

overpressure safety is achieved through the mutually supporting surfaces of both

halves of the capsule element

Standard version