| 产品型号 | TT-3302-1 | | Print Width 打印宽度 | 3.2M | | Number of print-heads 喷头数 | 双 喷头 | | Number of nozzle 喷嘴数 | 2880(180*8* 2) | | Resolution 精度 | 最高1440 dpi | | Color number 颜色 | Double 4 Color (双4色) | | Print table width 打印平台宽度 | 3.3M | | Speed 速度 | 2Pass: 68m2/h | 4Pass: 34m2/h | 6Pass: 24m2/h | 8Pass: 16m2/h | | Ink 油墨 | Aqueous / Eco-solvent ink (水性、弱溶剂) | | Software 软件 | PhotoPrint MainTop TitanPrint | | Control station 控制站 | Windows2000 /WindowsXP | | Work flow 工作流程 | Rip and print at the same time,print after Rip | | Operation Environment 运行环境 | 50hz/60hz,220v 10A | | Media type 物料种类 | Paper,Banner,Pvc,Mesh,Vinyl,Carpet纸, 广告布,Pvc,网状材料,即时贴,地毯等 | | Image format 图像格式 | Bitmap,Tiff,Jpeg,Eps,Pdf,Cad, | | Media Handling 物料处理 | Roll to roll,sheet by sheet | | Packing Size 包装尺寸 | 4.46M*0.76M*1.27M | | Net Weight 毛重量 | 750KG | | Remote controller 遥控器 | optional(选 配) | | Take up systerm 收料系统 | optional(选 配) |

| 1,自动清洗喷头、全功能压墨装置,确保墨路畅通,延长喷头寿命.客户可以选择喷绘过程中定时或手工启动自动清洗,自动闪喷。也可以起用强力压墨装置冲通墨路使墨路时时刻刻处在最佳状态,避免喷头堵塞。喷头更耐用。

2,前后两组加热系统、分组风干系统配合下喷结构,喷背胶更出色,经过后加热板的预热,背胶材料可以增加对油墨的吸附能力TRIDENT或128喷头强有力的喷绘,背胶画面和PVC一样做到色彩艳丽,画面无暇,风干系统可以根据湿度随意的调。

3,负压系统是由本公司自主研发的新产品.它包括负压发生器,负压缓冲器,带压力指示压力开关,数码显示及精密调压阀,二级墨盒位于喷头上方,墨盒与喷头之间墨管的距离减短了,从而减小了墨管的阻力.墨水更容易供到喷头,负压可视化,可调,能够达到适时控制的效果,产生负压的同时,也可以产生正压,方便的压墨清洗,使打印墨路更稳定,保证高速打印的基础。

4,机器上增加了安全瓶后,它能缓冲气压,同时保证压墨的时候气压的供应更稳定,工作中能有效的防止断墨情况。

5,金属三通阀,一边通墨水,一边通溶剂,清洗方便,能用按键达到溶剂自动清洗的更能,并能自动供墨,硅胶喷头扫用来擦喷头,既能达到清洁的效果,又不会损伤喷头,当机器不工作时装上喷头保护盒就能更好的保护喷头。

6,不锈钢喷嘴板,喷嘴板堵塞后既可用针筒冲,又可以用超声波震,还可以用无尘纸直接擦洗,都不会损伤喷嘴板,喷头两侧电路板可以拆下随意更换,即使某一个电子元件损坏,也完全可以维修,且维修起来非常方便,换过之后又是个全新的喷头,喷头内置加热系统,适合不同打印环境。

7,放布系统由两条圆轴支撑着材料,这样上起材料来就更方便.利用上方的粗细两根轴夹住布材料来拉,使材料更紧,不会打皱,自动收布系统,让开着机器打印而走开的你没有后顾之忧,能使机器在长时间工作中的到很好的材料供应,保证稳定的打印。

8,送布系统由两根圆轴支撑着材料,上起材料只需抬起来往上面一放即可,比较方便,送布是用两根轴夹住布来拉,然后用由大橡胶轴、 导轨钢轴多轴组合同步进布系统给予的张力使材料更紧,材料不会打皱。

9,打画时候,墨水挥发出来的废气被抽进净化器,废气由上面的管道进入,从下面的管道排出,净化器内部利用高科技多层过滤,墨水挥发出的废气被完全吸收,净化.净化后排出的气体不会对环境造成污染,完全达到环保的效果.这样赚钱,环保两不误。

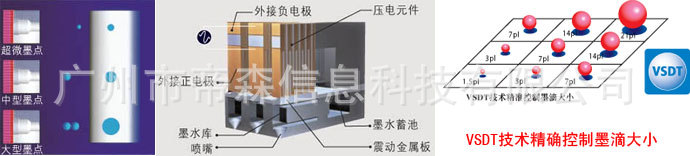

10,独有的微压电打印技术控制压电晶体变形,精确控制墨滴的大小,确保极出色的打印精度。在喷墨过程中使用温度补偿技术,确保了每个喷嘴工作的高频率和打印中的稳定性。采用智能墨滴可变点技术(VSDT),RIP处理时采用2比特的文件,根据图像来实时改变墨滴的大小,使用较大的墨滴来打印纯色区,较小的墨滴来表现精细的色调渐变和细节,VSDT在速度和图像质量间提供了完美的平衡,从而提高打印速度和精度,可以说VSDT是爱普生打印控制的灵魂技术。 | Mode | Titanjet 3302 | Print Width | 3.2M | Print Head | Epson DX5 | Number of Print-heads | 2 | Number of Nozzle | 1440(180*8*1) | Resolution | 1440 DPI | Color Number | Double 4 Color | Print Table Width | 3.3M | Print Speed | 2Pass: 68m2 /h | 4Pass: 34m2 /h | 6Pass: 24m2 /h | 8Pass: 16m2/h | Ink | Aqueous / Eco-solvent ink | Software | PhotoPrint MainTop | Control station | Windows2000, XP | Work flow | Rip and print at the same time, print after rip | Operation Environment | 50hz/60hz, 220v 10A | Media type | Paper, banner ,PVC, mesh, vinyl, carper and so on | Image format | Bitmap, Tiff, Jpeg, Eps, Pdf, Cad | Media Handling | Roll to roll , sheet by sheet | Remote controller | Optional | Take up system | Optional |

|

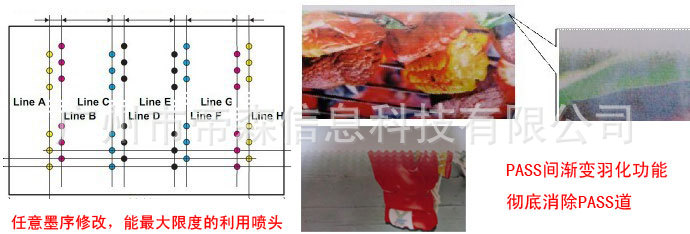

| Wave technology and gradient feathers, YMCK KCMY special arrangement to meet the order and from remote are the same color overlap, the depth of low-Pass Road will not be printed, and the gradual emergence of microwave technology to eliminate waves PASS Road.

|

| | The Variable Sized Droplet control technology (VSDT), demand drops automatically controlled, the output image color nuanced, rich layers, three-dimensional realistic, more delicate highlights, more vivid dark, more natural transition to color, shape beautiful realistic picture perfect. | We are the only manufacture who can make VSDT technology by self-developed in China. The Variable Sized Droplet control technology (VSDT), demand drops automatically controlled, the output image color nuanced, rich layers, three-dimensional realistic, more delicate high lights, more vivid dark, more natural transition to color, shape beautiful realistic picture perfect. Minimum 3.5pl droplet you could barely see the dots, into the "no-point print" new era.

Wave technology and gradient feathers, YMCK KCMY special arrangement to meet the order and from remote are the same color overlap, the depth of low-Pass Road will not be printed, and the gradual emergence of microwave technology to eliminate waves PASS Road.

User-friendly design, simple and easy to operate and maintained. Such as automatic vacuum cleaning, wipe the nozzle function, cleaning intensity is controlled by software which can control selection, the strength of all ink components of anti-solvent inks and cleaning fluids, wireless remote control to remotely operate a variety of print , pause, cleaning and so on.

stainless steel nozzle palte, while the nozzle plate been blocked ,it can use injector to blow as well as ultrasonic,another way is using dust-resistance paper to wipe directly and won't hurt nozzle plate,electronic board on two side of printhead can be separated to replace,even one electronic components been destroyed,it can be repaired completely and conveniencely,after replace it is a new printhead again! built-in heating system works well under any condition.

the exhaust gas vaporized by ink been pumped to the air purify machine while printing,the exhaust gas come into it through upper pipe,discharge from down pipe.air purify machine inside adopt hi-tech and multi-level filtration,exhaust gas vaporized by ink was purified completely,so won't pollute environment.it makes both benefit to make money and environment-protect.

Negative pressure device is a new product which researched and developed by Taotech CO.,LTD independently,it includes the Negative pressure ,Negative pressure buffer, show pressure switch,digital display and precise adjustable valve.Duoble-level ink box locates to the top of printhead,shortened the distances between ink box and printhead,reduced the length of ink tube thus weakened air-resistance,and ensure the fluent and stable of ink route.The negative value show on the negative pressure display,ensure the stability of negative pressture system.;

Negative pressure device can both generate negative pressure and positive pressure,so as to clean and purging ink stably and expediently. |

|

|