WIKA 432.56.100-831.21

带过压保护膜片式不锈钢电接点压力表

Diaphragm pressure gauge

with switch contacts

Model

432.56,

high overpressure safety up to 100

bar

Model 432.36, safety version, high overpressure safety up to 400

bar

Diaphragm pressure gauge model

432.56.100,

high overpressure safety up to 40 bar, with switch

contact

model 831.21

Applications

Control and regulation of industrial processes at

measuring points with increased overpressure and scale ranges from 0 … 25

mbar

Monitoring of plants and switching of electric circuits

For

gaseous and liquid, aggressive and highly viscous or contaminated media, also in

aggressive ambience

Process industry: Chemical, petrochemical, power

plants, mining, on- and offshore, environmental technology, machine building and

general plant construction

Special features

High overpressure safety, optionally up to 40, 100 or

400 bar, due to metallic diaphragm cushion, without liquidfilled measuring

cell

Wide choice of special materials

Also available with

liquid-filled case for high dynamic pressure loads or vibrations

Gauges

with inductive contacts for use in hazardous areas with ATEX

approval

Gauges with electronic contact for PLC applications

Description

Wherever the process pressure has to be indicated

locally, and, at the same time, circuits are to be made or broken, the model

432.56 or 432.36 switchGAUGE can be used.

Switch contacts (electrical alarm contacts) make or break an electric

control circuit dependent upon the position of the instrument pointer. The

switch contacts are adjustable over the full extent of the scale range (see DIN

16085), and are

mounted predominantly below the dial, though also partly on

top of the dial. The instrument pointer (actual value pointer) moves freely

across the entire scale range, independent ofthe setting.

The set pointer can be adjusted using a removable adjustment key in the

window.

Switch contacts consisting of several contacts can also be set to a

single set point. Contact actuation is made when the actual value pointer

travels beyond or below the desired set point.

The pressure gauge is manufactured in accordance with DIN 16085 and

fulfils all requirements of the relevant standards (EN 837-3) and regulations

for the on-site display of the working pressure of pressure vessels.

As switch contacts magnetic snap-action contacts, reed switches,

inductive contacts - for requirements to ATEX - or electronic contacts for

triggering a PLC are available.

For further information on the different switch contacts please

see

data sheet AC 08.01.

Standard version

Nominal size in mm

100, 160

Accuracy class

1.6

Scale ranges

0 ... 25 mbar to 0 ... 250 mbar (flange

Ø 160 mm) 1)

0 ... 400 mbar to 0 ... 40 bar (flange Ø 100 mm) 1)

or

all other equivalent vacuum or combined pressure and vacuum ranges

Pressure limitation

Steady: Full scale

value

Fluctuating: 0.9 x full scale value

Overpressure

safety

40, 100 or 400 bar

Permissible temperature

Ambient: -20 … +60 °C

Medium: +100 °C maximum

Temperature effect

When the temperature of the

measuring system deviates from the reference temperature (+20 °C):

max.

±0.8 %/10 K of full scale value

Process connection with lower measuring

flange

Stainless steel 316L, G ½ B (male), 27 mm flats

Pressure element

≤ 0.25 bar: Stainless steel

316L

> 0.25 bar: NiCr-alloy (Inconel)

Pressure chamber sealing

FPM/FKM

Movement

Stainless steel

Dial

Aluminium, white, black lettering

Pointer

Instrument pointer: Aluminium, black

Set

pointer: red

Case

Stainless steel, gauges with liquid filling with

compensating valve to vent case

Model 432.56: with blow-out

device

Model 432.36: safety version with solid baffle wall and blow-out

back

Upper measuring flange

≤ 0.25 bar: Chrome steel

> 0.25 bar: NiCr-alloy

Window

Laminated safety

glass

Bezel ring

Cam ring (bayonet type), stainless steel

Electrical connection

Terminal box

Ingress protection

IP 54 per EN 60529 / IEC

529

Switch contacts

Magnetic snap-action contact model

821

No control unit and no extra power supply required

Direct

switching up to 250 V, 1 A

Up to 4 switch contacts per measuring

instrument

Inductive contact model 831

Long service life due to

non-contact sensor

Additional control unit required (model 904)

With

corresponding control unit suitable for use in zone 1 /21 (2 GD) hazardous

areas

Low effect on the indication accuracy

Fail-safe switching at

high switching rates

Insensitive to corrosion

Up to 3 switch contacts

per measuring instrument

Electronic contact model 830 E

For direct triggering

of a programmable logic controller(PLC)

2-wire system (option: 3-wire

system)

Long service life due to non-contact sensor

Low effect on the

indication accuracy

Fail-safe switching at high switching rates

Insensitive to corrosion

Up to 3 switch contacts per measuring

instrument

Reed switch model 851

No control unit and no extra

power supply required

Direct switching up to 250 V, 1 A

Also suitable

for direct triggering of a programmable logic controller (PLC)

Free from

wear as without contact

Up to two change-over contacts per measuring

instrument

Switching function

The switching function of the

switch is indicated by function index 1, 2 or 3.

Model 8xx.1: Contact makes

(clockwise pointer motion)

Model 8xx.2: Contact breaks (clockwise pointer

motion)

Models 821.3 and 851.3: Change over; one contact breaks and one

contact makes simultaneously when pointer reaches set point

For further information please see data sheet AC 08.01, electrical switch contacts

Options

Other process connection

Sealings (model 910.17, see data sheet AC 09.08)

Liquid filling (models

433.56, 433.36, ingress protection IP 65)

Vacuum safe to -1 bar

Max.

medium temperature +200 °C

Higher indication accuracy, class 1.0

Open

connecting flanges per DIN/ASME from DN 15 to DN 80 (preferred nominal widths DN

25 and 50 or DN 1" and 2"; see data sheet IN 00.10)

Wetted parts made of

special materials, high overpressure safety up to 10 bar(flange Ø 160 mm) or 40

bar (flange Ø 100 mm): PTFE (models 452.56, 452.36), Hastelloy, Monel, nickel,

tantalum, titanium (accuracy class 2.5)

Inductive contacts also in safety

version (SN, S1N)

Special version

Model 432.36, high overpressure safety

up to 400 bar

Scale ranges:

0 ... 25 mbar to 0 ... 250 mbar

(flange Ø 190 mm)

0 ... 400 mbar to 0 ... 40 bar (flange Ø 120 mm)

Flange connecting screws: Steel, corrosion-protected

CE conformity

Pressure equipment directive

97/23/EC, PS > 200

bar, module A, pressure accessory

EMC directive

2004/108/EC, EN 61326 emission (group 1,

class B) and interference immunity (industrial application)

ATEX directive 1)

94/9/EC, II 2 G Ex ia IIC

Approvals 1)

ATEX, Design approval for connection to

hazardous zone 0

GOST, metrology/measurement technology, Russia

GOST-R, import certificate, Russia

KOSHA, ignition protection type „i“ -

intrinsic safety, South Korea

CRN, safety (e.g. electr. safety,

overpressure, ...), Canada

Certificates 1)

2.2 test report per

EN 10204 (e.g. state-of-the-art manufacturing, material proof, indication

accuracy)

3.1 inspection certificate per EN 10204 (e.g. material

proof

wetted parts metal component, indication accuracy)

1) Option

Approvals and certificates, see

website

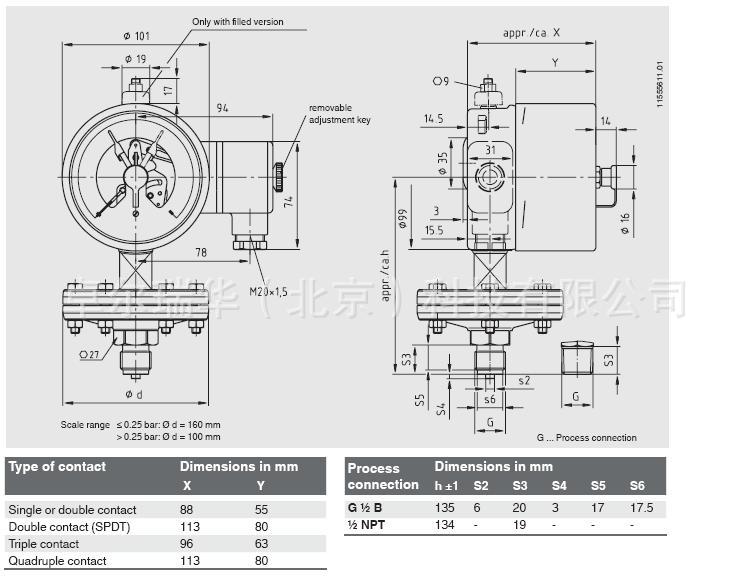

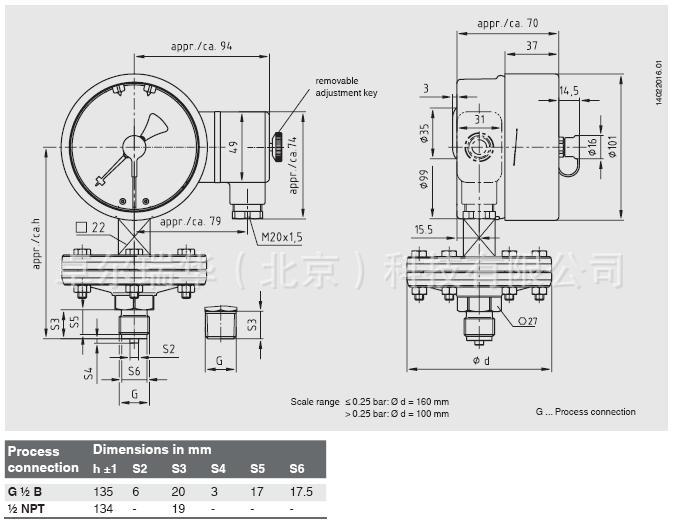

Dimensions in mm

switchGAUGE model 432.56.100, with switch contact model 821, 831 or 830

E

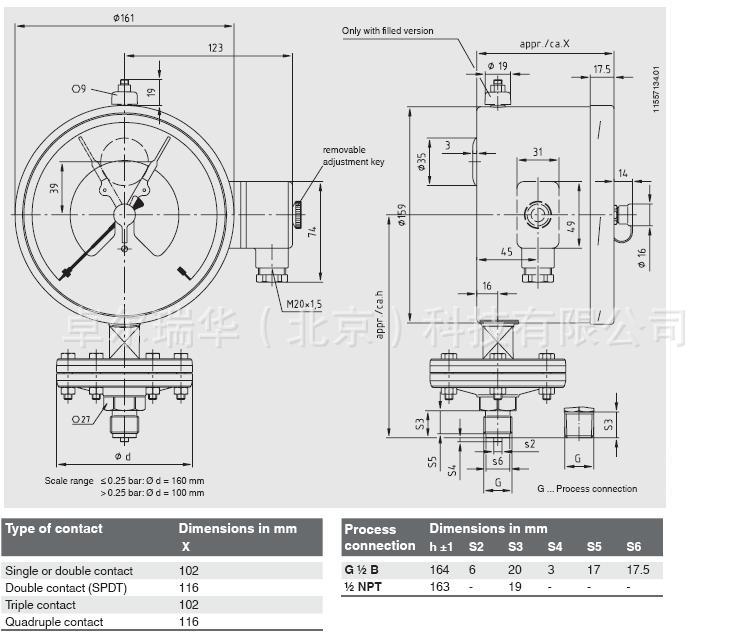

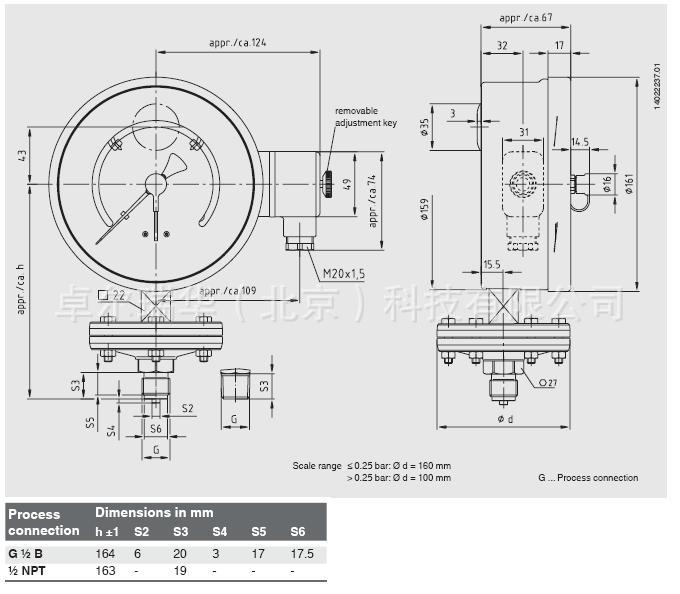

switchGAUGE model 432.56.160, with switch contact model

821, 831 or830 E

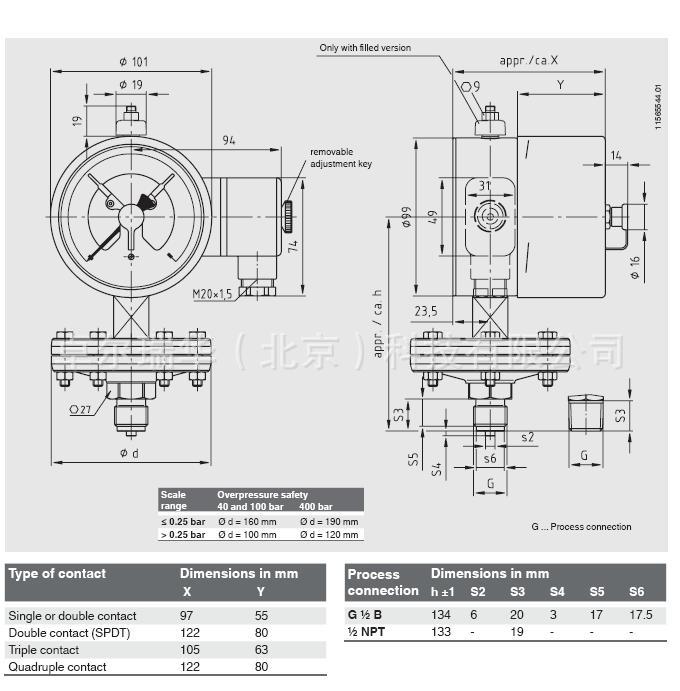

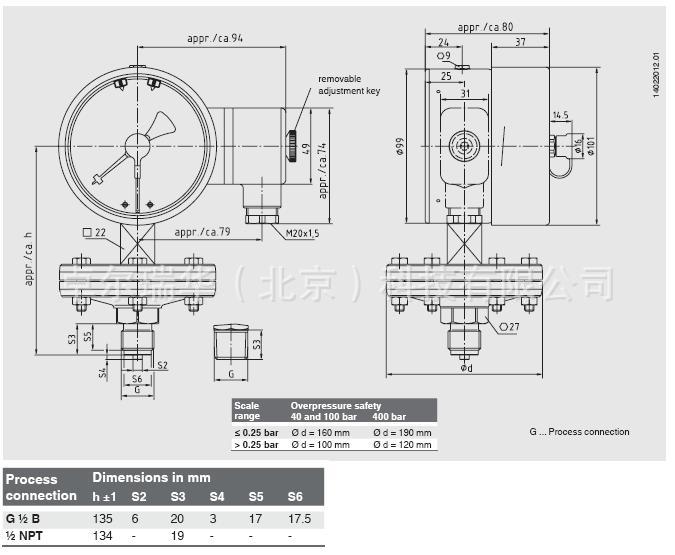

Option

switchGAUGE model

432.36.100, with switch contact model 821, 831 or 830 E

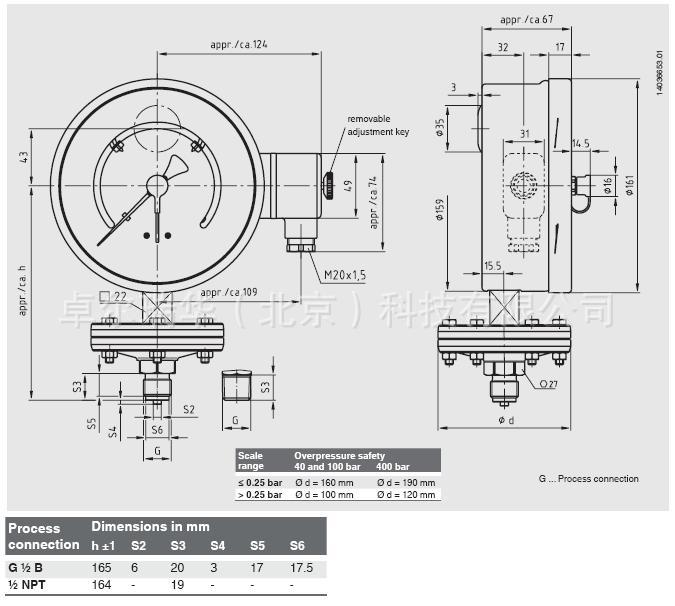

Option

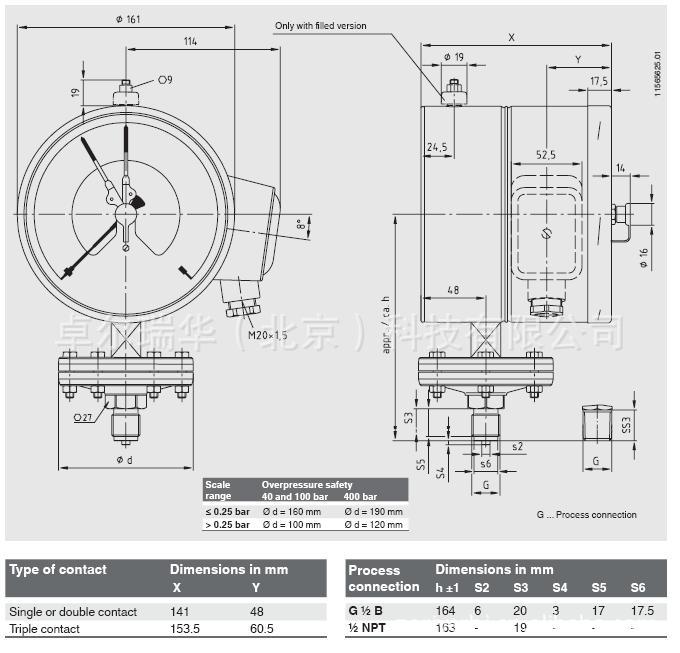

switchGAUGE model 432.36.160,

with switch contact model 821, 831 or 830 E

Dimensions in mm

switchGAUGE

model 432.56.100, with switch contact model 851.3 or 851.33

switchGAUGE model 432.56.160, with switch contact model 851.3 or

851.33

Option

switchGAUGE model

432.36.100, with switch contact model 851.3 or 851.33

Option

switchGAUGE model

432.36.160, with switch contact model 851.3 or 851.33

Ordering information

Model /

Nominal size / Overpressure safety up to ... bar / Scale range / Type of contact

and switching function / Connection

size / Options

欢迎致电咨询订购WIKA 432.56.100-831.21 带过压保护膜片式不锈钢电接点压力表

电话:010-51669912 56291930 15910733293

传真:010-51669912

QQ:823377546 1491421115 2636968574

邮箱:sales@zoriver.cn

公司官网: