纤维增强水泥板、硅酸钙板、天花吊顶板、外墙板, 大量出口中东, 东南亚,澳大利亚、西班牙、意大利、韩国等, 规格有1200x2400/1220x2440x5mm-18mm, 如有需求,请随时来电。

谢谢!

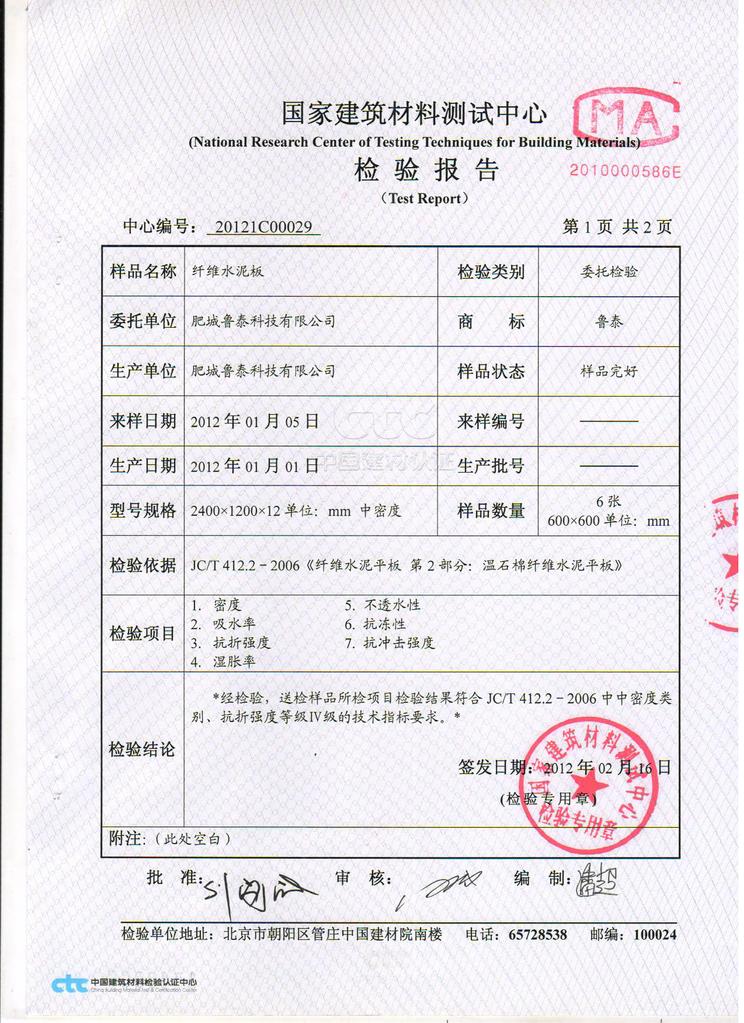

Fiber Cement Boardis mainly made of Portland cement and silicate materials as base and cellulose reinforced, forming inHatschek processand high pressure (4000Tpress machine for 15 minutes) and fumigation(inautoclavefor 24 hours),so it has the advantages ofhigh strength, light weight, anti- freeze, water-resist, fire-proof, damp-proof, sound-absorption , no distortion and no radiation...Etc.Used assuspended ceiling, partition, heat insulating board, base plate, billboard, external wall panel, exterior wall cladding, paneling, moving floor, desktop board, fire-resistant air pipe ,back-liners, skirting lines, prefabricated structures, door shutters …etc.

Applications: Business building, Entertainment facility, supermarket, hotel & restaurant, factory, warehouse, apartment building, hospital, theater and station etc.

Materials: Tobermorite, Portland cement, Quartz sand, cellulose fiber…

Fire-proof rate: A-class incombustible (GB8624-1997)

Incombustibility: 180 minutes (GB/T9978-1999)

Density: 1.3-1.6g/cm3

Moisture: <10%

Heat conduction: 0.24W/MK (Jc/t564) Average

Sound-absorption: 45db (GBJ75-84)

Anti-bend strength: >16MPa (GB/T7019-1997)

Moisture movement rate: <0.19% (GB/T7019-1997)

Dry shrinking rate: <0.09% (GB/T7019-1997)

Radiation rate: According with Standard (GB6566-2000)

Calcium Silicate Boardis mainly made of siliceous and calcareous materials as major and natural cellulose reinforced, forming inHatschek processand high pressure (4000 tons and fumigation(in autoclave for 24 hours),Which has the advantages ofhigh strength, light weight, anti- freeze, water-resist, fire-proof, damp-proof, sound-absorption , no distortion and no radiation...Etc.Used assuspended ceiling, partition, heat insulating board, base plate, external wall panel, exterior wall cladding, paneling, flooring, back-liners, skirting lines, prefabricated structures, door shutters …etc.

Applications: Business building, Entertainment facility, supermarket, hotel & restaurant, factory, warehouse, apartment building, hospital, theater and station etc.

Materials: Tobermorite, CaO, Quartz sand, cellulose fiber

Fire-proof rate: A-class incombustible (GB8624-1997)

Incombustibility: 180 minutes (GB/T9978-1999)

Density: 1.2-1.5g/cm3

Moisture: <10%

Heat conduction: 0.24W/MK (Jc/t564) Average

Sound-absorption: 45db (GBJ75-84)

Anti-bend strength: >15MPa (GB/T7019-1997)

Moisture movement rate: <0.19% (GB/T7019-1997)

Dry shrinking rate: <0.09% (GB/T7019-1997)

Radiation rate: According with Standard (GB6566-2000)

Acoustic boardhas remarkable function of absorbing sound except of high strength, light weight, anti-freeze, and water-resist, fire-proof and non- deformation, which has kinds of bore diameter to choose. Used assuspendedceiling, partition, exterior wall cladding…etc

The size: 595/600/603/1200/1206x4mm-8mm

Materials: Tobermorite, Quartz sand, cement, wood fiber.

Bore Diameter: 5/6/8/10mm

Perforation rate: 4-21%

Fire-proof rate: A-class incombustible (GB8624-1997)

Density: 1. 0-1.3g/cm3

Moisture: <10%

Radiation rate: According with Standard (GB6566-2000)

Production process

Prepare material (Tobermorite crystal , fly ash, Quartz sand, cellulose fiber…) →loose fiber→ blending (15 minutes) → blowing→forming in 1 time(Hatschek process)→ stacking(usually model by model)→pressurization (in order to make the fiber well-knit through evaporation with 4000 tons press machine for 15minutes)→nature conservation(make the boards have the prime strength)→mold release→steaming (1 standard atmosphere pressure for 24 hours )→prime checking→ sanding →edge trimming →packing→ quality inspection→ warehousing

1、Property contrast on common decorating materials

Item | “Lutai” Board ( calcium silicate & fiber cement board) | Gypsum Board | MgO Board | TK Board (Glass Fiber Cement Board) |

Raw Materials | Cement、Quartz Sand, Organic/Inorfil Cellulose Fiber | Gypsum、Paper | Magnesium Oxide、Magnesium Chloride | C-Glass、Short Mineral wool、LowAlkaliPortland |

Anti-Bend Strength(MPa) | ≥12 | 4~5 | ≤12 | 6~8 |

Fire-proof Rate | A-class incombustible (GB8624-1997) | Non-Flammable | incombustible | incombustible |

Incombustibility (min) | ≥240 | 60 | 50 | 70 |

Damp-proof Rate | After wetting, the strength drops by 20-40%, recovers by 100% after dryness | Distortion after wetting, beyond retrieve | Distortion after wetting, beyond retrieve | Distortion after wetting, beyond retrieve |

Use Age | Used for many years | Sagging because of absorbing the Moisture in the air, short lifetime | Sagging because of absorbing the Moisture in the air, short lifetime | Distortion after wetting, beyond retrieve, short lifetime |

2、Property contrast on common suspended ceilings materials:

Item | “Lutai” Board (calcium silicate & fiber cement board) | Gypsum Plaster Board | GF Board (Non-paper Gypsum Board) | Mineral Fiber Tile |

Raw Materials | Cement、Quartz Sand, Organic/Inorfil Cellulose Fiber | Gypsum、Paper | Gypsum、paper fiber、rock wool | Slag wool、adhesive |

Anti-Bend Strength(MPa) | ≥12 | 4~5 | 6~8 | ≥1.5 |

Fire-proof Rate | A-class incombustible (GB8624-1997) | Non-Flammable | incombustible | incombustible |

Incombustibility (min) | ≥240 | 60 | 85 | -- |

Damp-proof Rate | After wetting, the strength drops by 20-40%, recovers by 100% after dryness | Distortion after wetting, beyond retrieve | Distortion after wetting, beyond retrieve | Distortion after wetting, beyond retrieve |

Use Age | Used for many years | Sagging because of absorbing the Moisture in the air, short lifetime | Sagging because of absorbing the Moisture in the air, short lifetime | Distortion after wetting, beyond retrieve, short lifetime |