一、基本功能与特点介绍

ECON-08SS采用独特湿式分离法,是专利设计产品,近十年市场使用经验,集人性化需求、环保、安全、全球最先进技术为一体。主要针对波峰焊锡炉工作过程中产生的焊锡氧化物——锡渣,进行二次回收利用,将收集好的锡渣再投入,无需添加任何化学、非化学物质,能彻底、有效的将锡渣中可用焊锡分离回收,直接使用,节约焊锡使用量,节省成本。

本机是离线式独立操作,自动化程度高,分离效率高,处理能力强,具有废气处理系统。需配置废气抽风管道,建议配置独立厂房空间作业。适合大量同一成分锡渣的集中处理。

1, Introduction of the basic function and characteristics

ECON-08SS is a patent design product, using unique wet separation method. It has the market using experience for about 10 years and combines humanity demand, environmental protection, safety, the global most advanced technology as a whole. It is mainly aimed at tin soldering oxide— tin slag, produced by the process of wave soldering stove, for twice recovery. The tin slag collected can be put into stove again without adding any chemical or non chemical substance, and the tin available in slag can be separated for recovery and direct used, effectively and thoroughly, for the sake of saving tin amount and cost.

The machine is off-line independent operation, with a high automatic degree, separation rate and high processing capacity, equipped with exhaust gas processing system. It is better to equipped with exhaust gas convulsion pipe and independent factory space. It is suitable for the centralized processing of large amount tin slag with same component.

二、技术参数

项目 | 参数 | Items | Parameters |

ECON-08SS | 全自动高效锡渣分离机 | ECN-08SS | Automatic Efficient Tin Recovery machine |

控制系统 | PLC+温控模块+触摸屏 | Control system | PLC + Temperature Control modular + Touch screen |

分离方式 | 湿式分离法+螺旋离心分离 | Separation method | Wet separation + Screw centrifugal separation |

工作效率 | 50kg/h | Work efficient | 50kg/h |

锡渣分离率 | 锡渣含锡量的90%以上 | Tin separation rate | More than 90% of tin content in slag |

排锡方式 | 全自动检测排放、冷却收集 | Tin emission method | Automatic check emission,Cooling collection |

开机升温时间 | 60Min | Start heating-up time | 60Min |

自动下料容量 | φ25mm以下颗粒/20kg | Automatic filling capacity | Grain under φ25mm/20kg |

手动下料容量 | 60*70mm块状/5kg | Manual filling capacity | 60*70mm buck/5kg |

分离腔材质 | SUS316L(可选钛合金) | Separation cavity material | SUS316(Ti alloy optional) |

底锡总容量 | 100kg | Bottom tin total capacity | 100kg |

排风口尺寸 | 6寸 | Air outlet size | 6 inches |

废气环保处理 | 一级降温冷却,二级采用阻燃过滤棉+不锈钢网+水帘式过滤+活性碳过滤棉 | Exhaust air environment treatment | 1 lever cooling, and 2 lever uses inflame retarding cotton + stainless steel net + water curtain type filter + Activated carbon filter cotton |

总功率 | 6KW | Total power | 6 KW |

运行功率 | 1.8KW | Function power | 1.8KW |

电源 | 3相4线 AC380V 50Hz/60Hz | Power supply | 3-phase and 4-line AC380V 50Hz/60Hz |

净重 | 约600kg | Net weight | About 600kg |

机身尺寸(mm) | 1650(长)X1050(宽)X1550(高) | Machine size(mm) | 1650(length)X1050(width)X1550(height) |

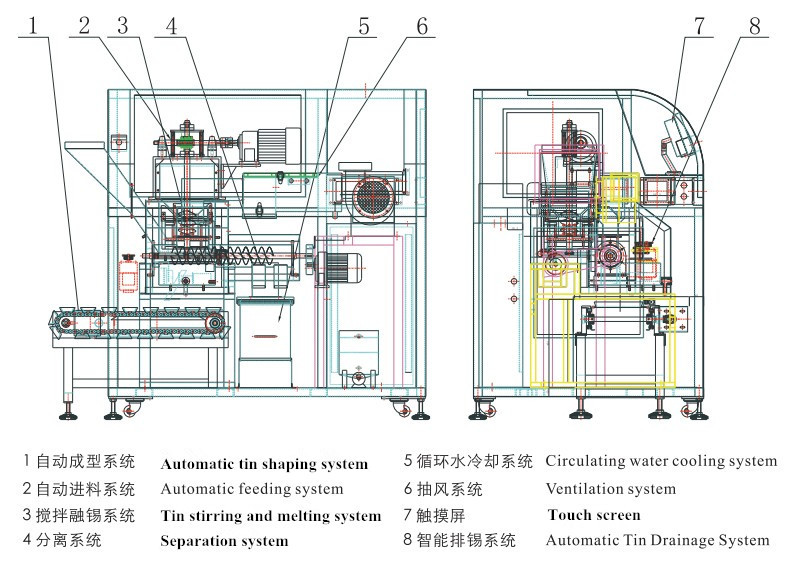

三、结构示意图

'