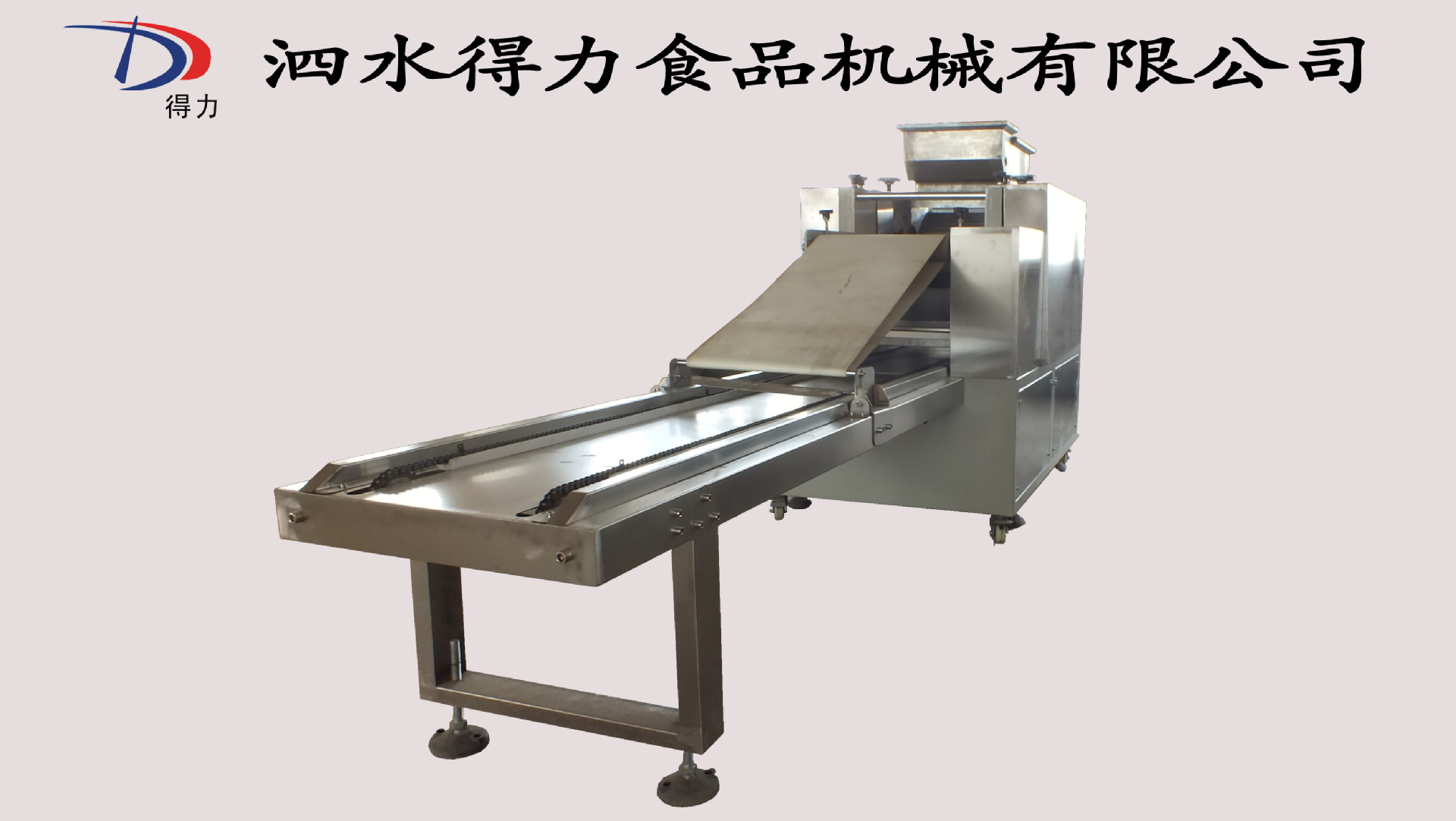

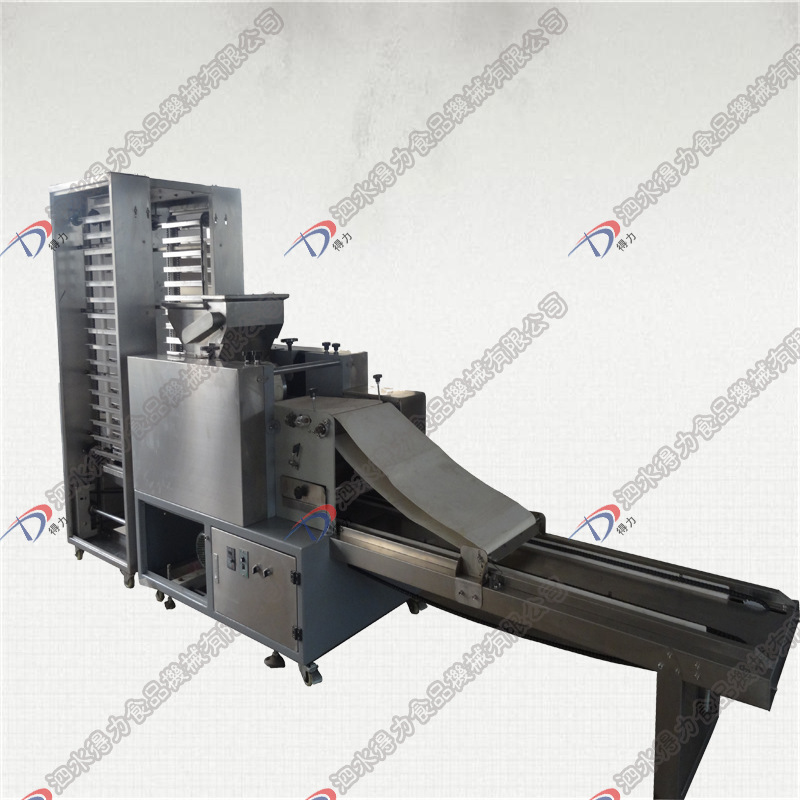

本机墙板采用18mm厚钢板,总高900mm,上面方便、稳固、无噪音、利用二次挡铁,二次落饼www.ccdeli.com,防止了漏面、咽面、早脱模、蜗轮、蜗杆升降胶辊灵巧、轻便。

本机墙板采用18mm厚钢板,总高900mm,上面方便、稳固、无噪音、利用二次挡铁,二次落饼www.ccdeli.com,防止了漏面、咽面、早脱模、蜗轮、蜗杆升降胶辊灵巧、轻便。

型号 model DL-400 DL-600 DL-800 DL-1000 DL-1200 功率power(k w) 1.5 2.2 3.0 4.0 4.0 外形尺寸 Overall dimensions (mm) 2350*900*1100 2400*1100*1150 2450*1300*1200 2450*1500*1300 2450*1600*1300 机器重量 Machine weight (kg) 900 950 1000 1150 1200 生产能力 Production capacity (kg/h) 100-300 200-400 300-500 400-700 500-800 1.桃酥机采用厚度S18、10#型钢板,钢性好,焊接牢固,而且便于移动(装有万向轮) 1. The thickness of the walnut cake machine adopts S18, 10 # steel plate, good rigidity, welding firmly, and facilitate mobile (with a universal wheel) 2. 桃酥机配二级落饼,模具无需,更换模具方便简捷,仅需0.5分钟,没有面渣、减少浪费。 2. Walnut cake machine with secondary fall pie, die without, mould replacement for ease-of-use, only 0.5 minutes, no residue, reduce waste. 3.桃酥机变频调速,运转平稳、耗能低,噪音低,生产效率高 3. Walnut cake machine frequency control of motor speed, smooth operation, low energy consumption, low noise, high production efficiency 4.桃酥机配有自动撒芝麻结构,芝麻附着效果好。 4. Walnut cake machine is equipped with automatic sprinkle sesame structure, sesame adhesion effect is good. 5.桃酥机机型轻巧,多用途,可制作各种饼干、桃酥等食品,生产速度变频调节,操作方便,机械耐用,保证长时间正常运行。 5. Walnut cake machine models and lighter, multi-purpose, can produce all kinds of biscuits, walnut cake, such as food, production speed frequency conversion adjustment, convenient operation, mechanical durability and ensure the normal operation of a long period of time. 6.桃酥机的工作原理为:将调制好的面料放入料斗,通过喂料辊及模具辊的喂料挤压,成为桃酥坯料,然后经过由胶辊带动的帆布带将坯料输送到烤盘上。托盘链条与模具同步运行,模具每旋转一周,即可摆成一盘,由此实现了自动连续生产的目的。 6. Walnut cake machine working principle is: will prepared material into the hopper, through the feed roller and die roller feeding extrusion, become a walnut cake billet, and then after driven by rubber roller will be blank canvas belt conveyor to the baking tray. Tray chain the synchronous operation and die, die each week, can be put into a plate, thus achieve the goal of the automatic continuous production. 7.桃酥机在结构上还设置了多处调节机构:帆布张紧调偏机构,分面刀左右及上下调节机构,帆布粘料清理刮面机构,喂料间隙调节机构等。可用于隧道式钢(网)带烤炉,隧道式链条烤炉,隧道式手推烤炉,及热风旋转烤炉。 7. Walnut cake machine is also equipped with several regulating mechanism in the structure: canvas tension adjusting mechanism, faceted knife around and regulating mechanism, up and down on canvas adhesive material clean shave institutions, feeding gap regulating mechanism and so on. Can be used in tunnel steel (network) with oven, tunnel oven chain, tunnel push oven, and hot air rotary oven. 机型轻巧,多用途,可制作各种饼干、桃酥等食品,生产速度变频调节,操作方便,机械耐用,保证长时间正常运行。 自动撒芝麻自动摆盘桃酥机 桃酥机由机架、托盘输送系统;帆布传动胶辊、喂料辊、分面刀、模具成形系统;自动撒芝麻机构;桃酥坯料自动摆盘机构等组成。其工作原理为:将调制好的面料放入料斗,通过喂料辊及模具辊的喂料挤压,成为桃酥坯料,然后经过由胶辊带动的帆布带将坯料输送到烤盘上。托盘链条与模具同步运行,模具每旋转一周,即可摆成一盘,由此实现了自动连续生产的目的。另外,该机在结构上还设置了多处调节机构:帆布张紧调偏机构,分面刀左右及上下调节机构,帆布粘料清理刮面机构,喂料间隙调节机构等。可用于隧道式钢(网)带烤炉,隧道式链条0烤炉,隧道式手推烤炉,及热风旋转烤炉。该机能生产各种圆酥、椭圆酥、方酥及酥性饼干、炉果等食品。 友情提示公司可为您提供配方。