High-temperature plat 硅酸铝陶瓷纤维高温毡

产品说明:

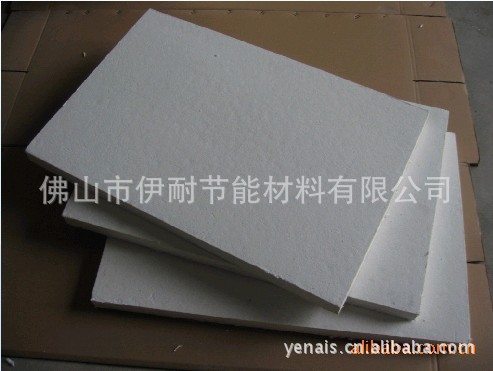

陶瓷纤维板采用散棉加无机粘合剂用湿法真空吸滤加压成形,并按不同型号经过高温锻烧处

理,该产品同时具备低容重高强度的优良特性,,是一种多用途产品,可应用于炉衬热面抗火焰和

高温气流直接冲击。

二、特点:

高温稳定

低导热率

低热容

抗热震

抗侵蚀

易加工和切割性能

精准的厚度与尺寸

良好的抗火焰及气流冲刷

安装使用方便

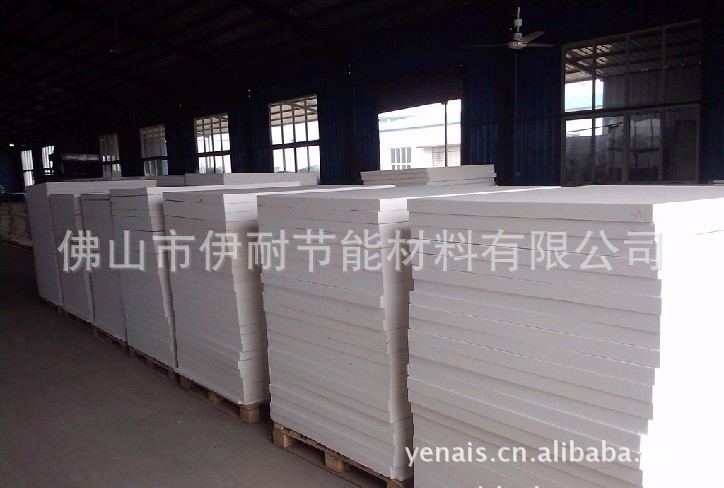

三、产品应用:

可应用于同时要求坚韧,自承重及隔热的领域,它具有良好的抗机械破坏性能。

领域包括:推板窑、钢包炉、钟罩窑、隧道窑、辊道窑、熔铝炉、热处理炉等绝热内

衬和背衬;高温挡火板;窑车隔热;各种高温工业窑炉隔热。

四、理化数据

型 号 | STD1000 | GP-1260 | HA-1420 | HG-1600 | 分类温度 ( o C) | 1000 | 1260 | 1420 | 1600 | 容 重 (kg/m 3 ) | 160-250 | 160-250 | 160-250 | 160-250 | 重烧线收缩 (%) | < 1.4(800oC

× 24hr) | < 1.3(1000oC

× 24hr) | < 1.5(1150oC

× 24hr) | < 2(1500oC

× 24hr) | 化

学

组

成

% | Al 2 O 3 | 37 | 42 | 30 | 65 | SiO 2 +Al 2 O 3 | >96 | 99 | 88 | >99 | Fe 2 O 3 | | 0.2 | 0.2 | - | ZrO 2 | - | - | 8 | - | | | | | |

产品规格(mm): 标准 600×400×20~50 900*600*20-50 |

I. Product Description:

Aluminosilicate Fiberboard increase the use of casual cotton inorganic adhesive wet filter vacuum pressure forming, and different models through high-temperature calcination Department

The rationale for the product at the same time with high-strength low-density fine features, is a multi-purpose products, lining can be applied to the flame and heat resistant surface

A direct impact on high-temperature airflow.

Second, characteristics:

High temperature stability

Low thermal conductivity

Low heat capacity

Thermal shock resistance

Anti-erosion

Easy processing and cutting performance

Precise thickness and size

Good anti-flame and air scour

The installation of easy-to-use

Third, product applications:

Requirements can be applied at the same time tough, since the load-bearing areas and thermal insulation, it has a good performance against mechanical damage.

Areas include: push board kiln, ladle furnace, Bell kiln, tunnel kiln, roller kiln, aluminum melting furnace, heat treatment furnace, such as insulation in

Lining and backing; high-temperature thermal block plate; kiln car insulation; a variety of high temperature industrial furnace insulation.

Fourth, physical and chemical data

Model

STD-1000

HP-1260

HA-1420

HG-1600

Classification temperature (o C)

1000

1260

1420

1600

Bulk density (kg / m 3)

160-250

160-250

160-250

160-250

Re-burned linear shrinkage (%)

× 24hr)

× 24hr)

× 24hr)

× 24hr)

Of

Science

Group

Into

%

Al 2 O 3

37

42

30

65

SiO 2 + Al 2 O 3

> 96

99

88

> 99

Fe 2 O 3

0.2

0.2

--

ZrO 2

--

--

8

--