'

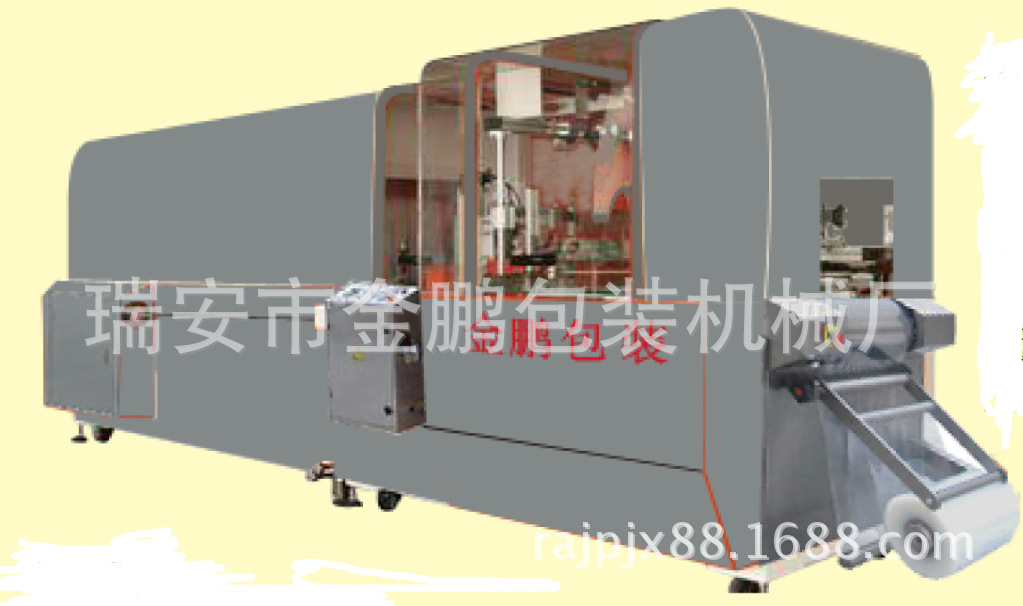

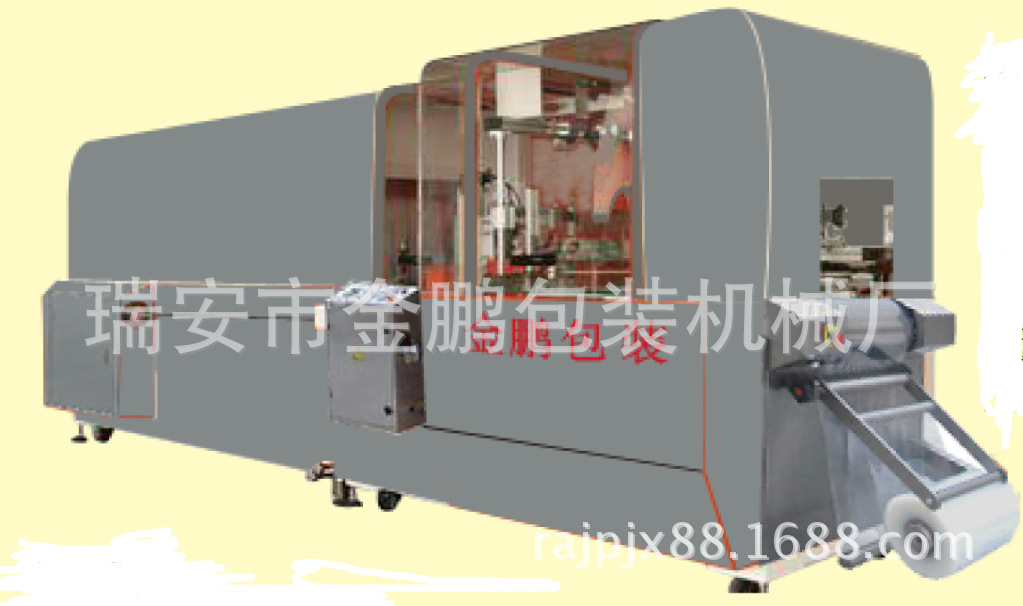

【行业推荐】 DLW-1012Z系列全自动卧式真空包装机 市场新宠儿

袋 长 范 围 | 70-250 mm(可调) |

袋 宽 范 围 | 50-200 mm(可调) |

包装物 厚 度 | 0.2-30mm |

包 装 速度 | 10-80袋/分 (按照包装列数不同) |

包材最大宽度 | 1012 mm |

真空泵功率 | 2.2KW |

电 源 | 380V 50Hz |

总 功 率 | 6.5Kw |

机 器 重 量 | 1800 Kg |

机 器 尺 寸 | 6300mm×1000mm×1600mm(长×宽×高 |

真空度 | ≤200Pa |

适用范围:

Scope of application:

本机适用于熟食品、卤制食品(鸡翅、凤爪、五香干,牛肉、鱿鱼等)、榨菜、炒货类、干货类。加料、制袋、封口、裁切全自动完成,并带有自动抽真空、计数;配碳带日期打印;自动控温,自动光电跟踪,变频无极调速。

This machine is suitable for cooked food, spiced food (chicken wings, chicken, spicy dry, beef, squid etc.), mustard, roasted seeds and nuts, dry cargo class. Feeding, bag making, sealing, cutting is finished automatically, and with automatic vacuum pumping, count; with ribbon date printing; automatic temperature control, automatic photoelectric tracking, frequency conversion stepless speed regulation.

功能特点:

Function characteristics:

1.性能先进.在真空包装机基础上制袋和包装一步到位。

2.自动化程度高。本机从卷膜分切打码反转、充填装料、纵封纵切、切易撕口、横封横切、直至成品袋输出能连续一次性完成。

3.次用高精度体滚压式热封滚轮作为纵封模具,连续牵行滚压,确保封口致密严实,袋形平整,精致美观。

4.调整快捷方便。不需要更换模具就可以进行袋长无级调整。且纵封、充填料、打批号、横封横切等执行机构均可通过人机界面进行调整。

5.整机采用进口PLC控制,各执行机构全部采用伺服电机驱动,使各执行机构均能精确自动同步定位。

6.采用光电跟踪系统,保证了包装袋双面图案对版。

1 advanced performance. Making based on vacuum packaging machine and packaging in one step.

2 high degree of automation. This machine from the film cutting code inversion, filling loading, vertical slitting, cutting easy tearing notches, transverse sealing cutting, until the finished bag output can continuously complete.

3 high precision body rolling type heat sealing wheel as longitudinal sealing mould, continuous traction for rolling, to ensure the sealing tightly, a smooth, delicate and beautiful.

4 convenient and quick adjustment. Does not require the replacement of mold can be stepless adjustment bag length. And the vertical sealing, filling, batch number, transverse sealing cutting actuators can be adjusted through the man-machine interface.

5 the machine adopts imported PLC control, the implementation mechanism adopts the servo motor drive, so that the implementing agencies can accurate positioning automatic synchronization.

6 photoelectric tracking system is adopted to ensure the packing bag, double side pattern on version.

'