Chomerics Soft-Shield 3700导电泡棉

SOFT-SHIELD® 3700 fabric over foam (fof), is a lowclosure force EMI gasket rated to be used in higher temperature applications (maximum temperature 125°C). This enables fabric over foam type gaskets to be used in applications where temperature requirements are greater than 70°C. Most fof’s in today’s market use urethane foam cores, this means

when brought above 70°C the products takes a major compression set. The temperature range for SOFTSHIELD

3700 is -40°C to 125°C.

The SOFT-SHIELD 3700 material fits a need in the automotive market place for low cost, low closure force, high temperature EMI/ESD gasketing. It is ideal for medical and military applications that require EMI shielding in higher temperatures. SOFT-SHIELD 3700 is also ideal for IT and telecom applications that have been pushing 85°C operating temperatures.

The SOFT-SHIELD 3700 product is comprised of a conductive fabric wrapped around a soft cellular silicone foam that relies on wrap around technology to ground the gasket from point to point ultimately eliminating an EMI gap.Profiles are engineered to optimize mechanical form fit and function while optimizing electrical performance.

This technical data sheet will address the most common type fof Chomerics has to offer to market, contact Parker Chomerics for any other special requirements and an updated profile list.

SOFT-SHIELD 3700 typically requires less then 1lb/in (0.175/mm) closure force, making it effective for low closure force applications and compression. SOFTSHIELD 3700 takes less the 7% compression set which is less than most other fof’s on the market resulting in reliable/repeatable shielding performance. SOFTSHIELD 3700 is an excellent alternative shielding solution replacing traditional spring finger type products.

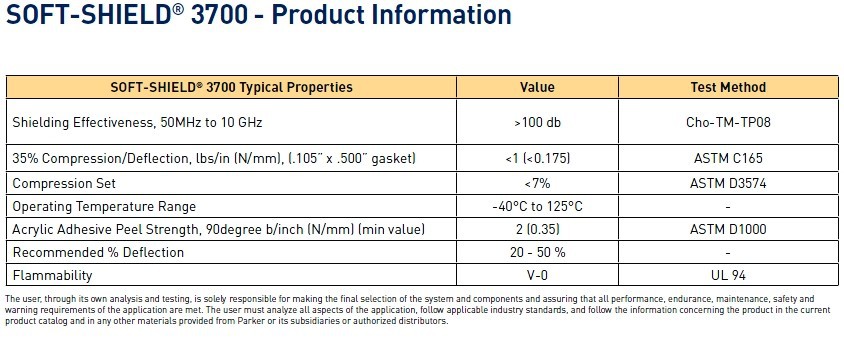

SS3700技术参数如下:

截面形状多,可选形状编码如下:

Profile Shape Height

(Inches)

Height

(Metric)

Width

(Inches)

Width

(Metric)

1008 Rect. 0.075 1.9 0.118 3.0

1003 Rect. 0.075 1.9 0.157 4.0

1011 Rect. 0.075 1.9 0.197 5.0

1004 Rect. 0.075 1.9 0.236 6.0

1012 Rect. 0.075 1.9 0.276 7.0

1005 Rect. 0.075 1.9 0.315 8.0

1013 Rect. 0.075 1.9 0.394 10.0

1014 Rect. 0.075 1.9 0.472 12.0

1009 Rect. 0.075 1.9 0.500 12.7

1015 Rect. 0.075 1.9 0.591 15.0

1016 Rect. 0.075 1.9 0.827 21.0

1017 Rect. 0.075 1.9 0.984 25.0

1006 Rect. 0.075 1.9 1.378 35.0

1007 Rect. 0.075 1.9 1.614 41.0

1010 Rect. 0.075 1.9 1.890 48.0

1024 Rect. 0.105 2.7 0.157 4.0

1018 Rect. 0.105 2.7 0.197 5.0

1023 Rect. 0.105 2.7 0.236 6.0

1021 Rect. 0.105 2.7 0.264 6.7

1025 Rect. 0.105 2.7 0.375 9.5

1022 Rect. 0.105 2.7 0.394 10.0

1020 Rect. 0.105 2.7 0.512 13.0

1019 Rect. 0.105 2.7 0.826 21.0

1027 Rect. 0.137 3.5 0.197 5.0

1026 Rect. 0.137 3.5 0.354 9.0

1028 Rect. 0.137 3.5 0.512 13.0

1029 Rect. 0.137 3.5 0.826 21.0

1030 Rect. 0.2 5.1 0.137 3.5

1033 Rect. 0.2 5.1 0.2 5.1

1031 Rect. 0.2 5.1 0.295 7.5

1035 Rect. 0.2 5.1 0.315 8.0

1034 Rect. 0.2 5.1 0.394 10.0

1036 Rect. 0.2 5.1 0.591 15.0

1032 Rect. 0.2 5.1 1.949 49.5

1037 Rect. 0.262 6.7 0.512 13.0

1038 Rect. 0.262 6.7 1 25.4

1041 Rect. 0.387 9.8 0.394 10.0

1039 Rect. 0.387 9.8 0.591 15.0

1040 Rect. 0.387 9.8 0.787 20.0

1043 Rect. 0.387 9.8 0.787 20.0

1042 Rect. 0.394 10.0 0.262 6.7

1045 Rect. 0.512 13.0 0.387 9.8

1044 Rect. 0.512 13.0 0.512 13.0