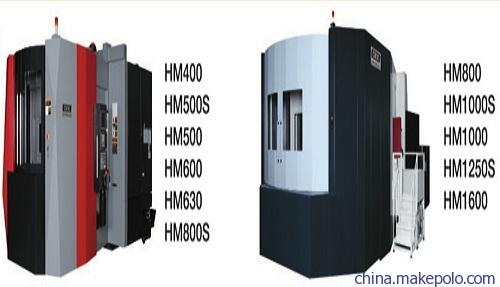

Compact Design

Space-saving design for effective use of floor space. The column moves to

right and left on the X axis, while the pallet moves back and forth on the

Z axis. This configuration reduces the required floor space more then 30%

compared with our previous machines.

Large Workpiece Capacity

800* mm-square pallet is capable of loading maximum 1200*kg and a

large-size workpiece of maximum 1110*mm in height and 1300 mm in diameter

* in case of HM800S

High-Speed ATC

OKK's original high-speed synchronous tool changer ensures tool change

operations and unmathced durability. It has achieved and ATC time of 2

seconds (tool-to-tool).

The ATC can change tools weighting up to 25kg. The variable-speed ATC

function assures smooth change of heavy tools.

Efficient Chip Disposal

The flushing coolant on both sides of the bed removes chips completely, and

the steel angle side shutter protects the Z-axis slideway. Swarf falls from

the shutter section to the troughs on both sides of the bed for efficient

removal. Since removed swarf is collected outside of the machine, swarf

disposal is easy. (Internal coil conveyor is also available as an

option).

Swarf processing efficiency can be further improved by combining a ceiling

shower (option). |

|