供应177-296三丰0.001MM钢制校正环规现货MITUTOYO

基本规格:

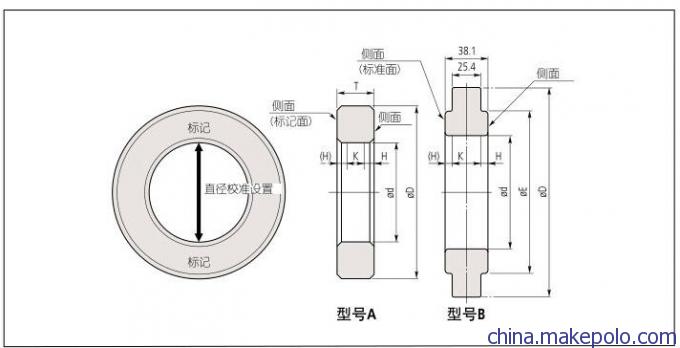

尺寸 ød | 货号 | 尺寸 (mm) | 型号 | 精度 | ||||||

øD | øE | T | 实际尺寸 与实际公 差 (µm) | 标准精度 (µm) | 圆度/圆 柱形状 (µm) | 侧距离 (mm) | 测力 (mm) | |||

1mm | 177-220 | 20 | — | 4 | A | ±10 | ±1.5 | 1 | 1.6 | 0.8 |

1.1mm | 177-222 | 20 | — | 4 | A | ±10 | ±1.5 | 1 | 1.6 | 0.8 |

1.2mm | 177-225 | 20 | — | 4 | A | ±10 | ±1.5 | 1 | 1.6 | 0.8 |

1.3mm | 177-227 | 20 | — | 4 | A | ±10 | ±1.5 | 1 | 1.6 | 0.8 |

1.4mm | 177-230 | 20 | — | 4 | A | ±10 | ±1.5 | 1 | 1.6 | 0.8 |

1.75mm | 177-236 | 25 | — | 5 | A | ±10 | ±1.5 | 1 | 1.6 | 1.8 |

2mm | 177-239 | 25 | — | 5 | A | ±10 | ±1.5 | 1 | 1.6 | 1.8 |

2.25mm | 177-242 | 25 | — | 5 | A | ±10 | ±1.5 | 1 | 1.6 | 1.8 |

2.5mm | 177-208 | 25 | — | 7 | A | ±10 | ±1.5 | 1 | 1.7 | 3.6 |

2.75mm | 177-246 | 25 | — | 7 | A | ±10 | ±1.5 | 1 | 1.7 | 3.6 |

3mm | 177-248 | 25 | — | 7 | A | ±10 | ±1.5 | 1 | 1.7 | 3.6 |

3.25mm | 177-250 | 25 | — | 7 | A | ±10 | ±1.5 | 1 | 1.7 | 3.6 |

3.5mm | 177-252 | 25 | — | 7 | A | ±10 | ±1.5 | 1 | 1.7 | 3.6 |

3.75mm | 177-255 | 25 | — | 7 | A | ±10 | ±1.5 | 1 | 1.7 | 3.6 |

4mm | 177-204 | 25 | — | 7 | A | ±10 | ±1.5 | 1 | 1.7 | 3.6 |

4.5mm | 177-257 | 25 | — | 7 | A | ±10 | ±1.5 | 1 | 1.7 | 3.6 |

5mm | 177-205 | 25 | — | 7 | A | ±10 | ±1.5 | 1 | 1.7 | 3.6 |

5.5mm | 177-263 | 25 | — | 7 | A | ±10 | ±1.5 | 1 | 1.7 | 3.6 |

6mm | 177-267 | 25 | — | 7 | A | ±10 | ±1.5 | 1 | 1.7 | 3.6 |

6.5mm | 177-271 | 25 | — | 7 | A | ±10 | ±1.5 | 1 | 1.7 | 3.6 |

7mm | 177-275 | 25 | — | 7 | A | ±10 | ±1.5 | 1 | 1.7 | 3.6 |

8mm | 177-125 | 32 | — | 10 | A | ±10 | ±1.5 | 1 | 2.0 | 6.0 |

9mm | 177-279 | 32 | — | 10 | A | ±10 | ±1.5 | 1 | 2.0 | 6.0 |

10mm | 177-126 | 32 | — | 10 | A | ±10 | ±1.5 | 1 | 2.0 | 6.0 |

12mm | 177-284 | 32 | — | 10 | A | ±10 | ±1.5 | 1 | 2.0 | 6.0 |

14mm | 177-132 | 38 | — | 10 | A | ±10 | ±1.5 | 1 | 2.0 | 6.0 |

16mm | 177-177 | 45 | — | 10 | A | ±10 | ±1.5 | 1 | 2.0 | 6.0 |

17mm | 177-133 | 45 | — | 10 | A | ±10 | ±1.5 | 1 | 2.0 | 6.0 |

18mm | 177-285 | 45 | — | 10 | A | ±10 | ±1.5 | 1 | 2.0 | 6.0 |

20mm | 177-286 | 45 | — | 10 | A | ±10 | ±1.5 | 1 | 2.0 | 6.0 |

25mm | 177-139 | 53 | — | 15 | A | ±10 | ±1.5 | 1 | 3.2 | 8.6 |

30mm | 177-288 | 71 | — | 15 | A | ±10 | ±1.5 | 1 | 3.2 | 8.6 |

35mm | 177-140 | 71 | — | 15 | A | ±10 | ±1.5 | 1 | 3.2 | 8.6 |

40mm | 177-290 | 71 | — | 15 | A | ±10 | ±1.5 | 1 | 3.2 | 8.6 |

45mm | 177-178 | 85 | — | 15 | A | ±10 | ±1.5 | 1 | 3.7 | 7.6 |

50mm | 177-146 | 85 | — | 20 | A | ±20 | ±1.5 | 1 | 3.7 | 12.6 |

60mm | 177-292 | 112 | — | 20 | A | ±20 | ±1.5 | 1 | 3.7 | 12.6 |

62mm | 177-314 | 112 | — | 20 | A | ±20 | ±1.5 | 1.5 | 3.7 | 12.6 |

70mm | 177-147 | 112 | — | 20 | A | ±20 | ±1.5 | 1.5 | 3.7 | 12.6 |

75mm | 177-316 | 125 | — | 25 | A | ±20 | ±1.5 | 1.5 | 4.2 | 16.6 |

80mm | 177-294 | 125 | — | 25 | A | ±20 | ±1.5 | 1.5 | 4.2 | 16.6 |

87mm | 177-318 | 140 | — | 25 | A | ±20 | ±1.5 | 1.5 | 4.2 | 16.6 |

90mm | 177-148 | 140 | — | 25 | A | ±20 | ±1.5 | 1.5 | 4.2 | 16.6 |

100mm | 177-296 | 160 | — | 25 | A | ±20 | ±1.5 | 2 | 4.2 | 16.6 |

125mm | 177-298 | 210 | 168 | 38.1 (25.4) | B | ±20 | ±1.5 | 2 | 5.3 | 27.5 |

150mm | 177-300 | 235 | 187 | B | ±20 | ±1.5 | 2 | 5.3 | 27.5 | |

175mm | 177-302 | 260 | 215 | B | ±20 | ±1.5 | 2.5 | 5.3 | 27.5 | |

200mm | 177-304 | 311 | 244 | B | ±20 | ±1.5 | 2.5 | 5.3 | 27.5 | |

225mm | 177-306 | 337 | 264 | B | ±20 | ±1.5 | 2.5 | 5.3 | 27.5 | |

250mm | 177-308 | 362 | 290 | B | ±20 | ±1.5 | 3 | 5.3 | 27.5 | |

275mm | 177-310 | 413 | 321 | B | ±20 | ±1.5 | 3 | 5.3 | 27.5 | |

300mm | 177-312 | 438 | 340 | B | ±20 | ±1.5 | 3 | 5.3 | 27.5 | |

三、相关介绍:

量规(gauge),不能指示量值,只能根据与被测件的配合间隙、透光程度或

仪器量规

仪器量规

者能否通过被测件等来判断被测长度是否合格的长度测量工具。量规控制的是尺寸或规格的上下限,一般包含全部的公差带

量规结构简单,通常为具有准确尺寸和形状的实体,如圆锥体、圆柱体、块体平板、尺和螺纹件等。常用的量规有量块、角度量块、多面棱体、正弦规、直尺、平尺、平板、塞尺 、平晶和极限量规等 。用量规检验工件通常有通止法(利用量规的通端和止端控制工件尺寸使之不超出公差带)、着色法(在量规工作表面上涂上一薄层颜料,用量规表面与被测表面研合,被测表面的着色面积大小和分布不均匀程度表示其误差)、光隙法(使被测表面与量规的测量面接触,后面放光源或采用自然光,根据透光的颜色可判断间隙大小,从而表示被测尺寸 、形状或位置误差的大小)和指示表法(利用量规的准确几何形状与被测几何形状比较,以百分表或测微仪等指示被测几何形状误差)。其中利用通止法检验的量规称为极限量规(如卡规、光滑塞规、螺纹塞规、螺纹环规等)。

四、陶瓷规:尺寸 ød | 货号 | 尺寸 (mm) | 型号 | 精度 | ||||||

øD | øE | T | 实际尺寸 与实际公 差 (µm) | 标准精度 (µm) | 圆度/圆 柱形状 (µm) | 侧距离 (mm) | 测力 (mm) | |||

4mm | 177-418 | 25 | — | 7 | A | ±10 | ±1.5 | 1 | 1.7 | 3.6 |

6mm | 177-420 | 25 | — | 7 | A | ±10 | ±1.5 | 1 | 1.7 | 3.6 |

8mm | 177-423 | 32 | — | 10 | A | ±10 | ±1.5 | 1 | 2.0 | 6.0 |

10mm | 177-424 | 32 | — | 10 | A | ±10 | ±1.5 | 1 | 2.0 | 6.0 |

12mm | 177-425 | 45 | — | 10 | A | ±10 | ±1.5 | 1 | 2.0 | 6.0 |

16mm | 177-427 | 45 | — | 10 | A | ±10 | ±1.5 | 1 | 2.0 | 6.0 |

20mm | 177-429 | 45 | — | 10 | A | ±10 | ±1.5 | 1 | 2.0 | 6.0 |

25mm | 177-430 | 53 | — | 15 | A | ±10 | ±1.5 | 1 | 3.2 | 8.6 |

30mm | 177-431 | 71 | — | 15 | A | ±10 | ±1.5 | 1 | 3.2 | 8.6 |

35mm | 177-432 | 71 | — | 15 | A | ±10 | ±1.5 | 1 | 3.2 | 8.6 |

40mm | 177-433 | 71 | — | 15 | A | ±10 | ±1.5 | 1 | 3.2 | 8.6 |

45mm | 177-434 | 85 | — | 15 | A | ±10 | ±1.5 | 1 | 3.2 | 8.6 |

供应177-296三丰0.001MM钢制校正环规现货MITUTOYO

供应177-296三丰0.001MM钢制校正环规现货MITUTOYO

供应177-296三丰0.001MM钢制校正环规现货MITUTOYO

供应177-296三丰0.001MM钢制校正环规现货MITUTOYO