DELTA ELECTRONIC GROUP LTD.

帝鋒電子集團有限公司

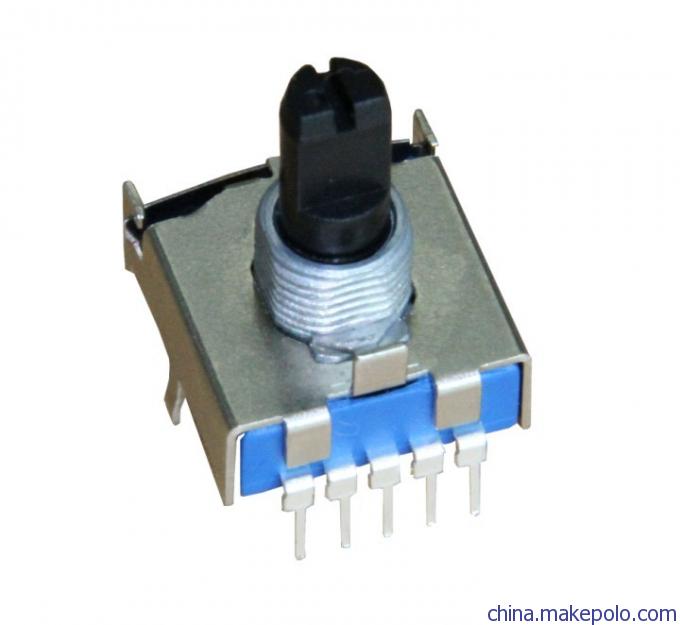

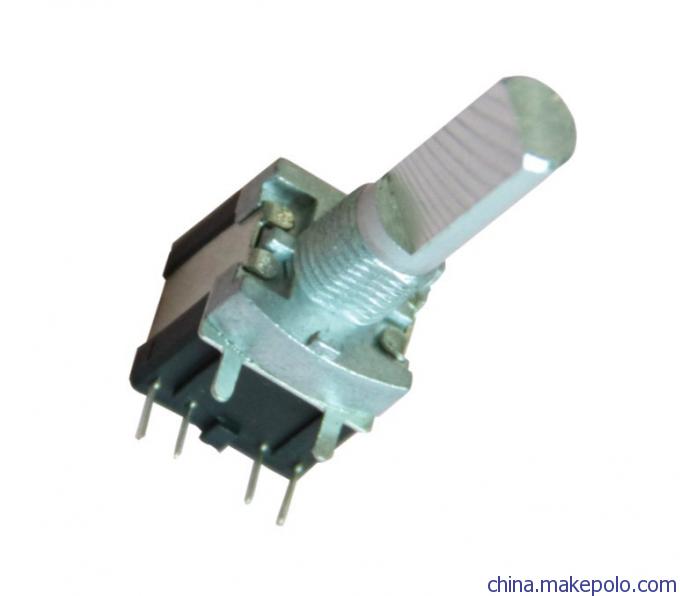

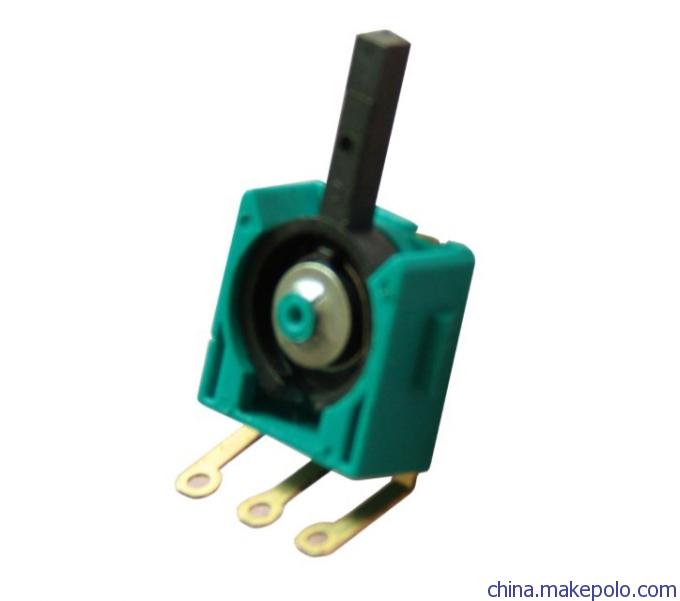

E12X4 SERIES

PRODUCT SPECIFICATION

産品規格書

1 General Characteristics一般特性

1.1 Scope: This specification applied to12mmsize low-profile rotary encoder for micro current circuits, used in electronic

equipment.

範圍 : 此規格應用於12mm小型旋轉編碼器,適用於電子設備內之微型電流電路,。

1.2 Standard atmospheric conditions標準测试环境 :

Unless otherwise specified, the standard range of atmospheric conditions for making measurements and tests is as follows:

除非另有說明,製造與檢測的標準範圍與氣候條件如下:

Ambient temperature 周圍環境:15℃to35℃

Relative humidity 相對濕度: 25% to 85%

Air pressure氣壓 : 86kPa to 106kPa

If there is any doubt about the results, measurements shall be made within the following limits :

若是因周圍環境影響而有不確定的測試值,則其測試條件變更如下列所述:

Ambient temperature周圍環境 : 20 ±1℃

Relative humidity相對濕度 : 63% to 67%

Air pressure氣壓 : 86kPa to 106kPa

1.3 Operating temperature使用溫度:-10℃to +70℃

1.4 Storage temperature儲存溫度:-20℃to +80℃

2 DIMENSIONS尺寸Dimensions: Refer to the separate product drawing參見成品圖

3 RATING額定3.1 Rated voltage額定電壓: DC 5V

3.2 Operating current使用電流

Each lead 每个信号端: 0.5 mA (max. 5mA , min. 0.5 mA)

Common lead共同端: 1 mA (max. 10mA , min. 0.5 mA)

4 ELECTRICAL CHARACTERISTICS電氣特性

Item | Content 项目 | Test Condition 測試條件 | Specification 規格 | |||||||

4.1 | Output signal format 輸出信號 |

(fig 1 )圖1: | 2 Phase-different signals (Signal A, signal B),Details shown in(fig.1). (The broken line shows detent position of with-detent type.) A、B兩信號輸出相位差,詳細見(圖1) (帶定位時,定位位置如下圖所示) | |||||||

Shaft rotational direction 軸回轉方向 | Signal 信號 | Output 輸出波形 ( 图1) |

| |||||||

C.W. 順時針方向 | A(Terminal A-C) A( A-C端子間) |

|

| |||||||

B(Terminal B-C) B( B-C端子間) |

|

| ||||||||

C.C.W. 逆時針方向 | A(Terminal A-C) A( A-C端子間) |

|

| |||||||

B(Terminal B-C) B( B-C端子間) |

|

| ||||||||

4.2 | Resolution 分解能力 | Number of pulses in 360° rotation。 回轉360°的輸出脈衝數。 | Refer to the separate product drawing 參見成品圖 | |||||||

4.3 | Switching characteristics 電位切換特性 | Measurement shall be made under the condition as follows. 1)Shaft rotational speed : 360°/S 2)Test circuit : (fig.2) 下(圖2)所示回路,軸以每秒360° 的速度回轉測定。

(Note) Code-OFF area :The area which the voltage is 3.5V or more. (注)編碼器OFF指輸出電壓3.5V以上的狀態。 Code-ON area :The area which the voltage is 1.5V or less. 編碼器ON指輸出電壓1.5V以下的狀態。 | ||||||||

(1) | Fluttering (Contact) 接觸彈跳雜訊 | Specified by the signal’s passage time from 1.5V to 3.5V or from 1.5V to 3.5V of each switching position (code OFF~ON or ON~OFF) 訊號從從3.5V切換到1.5V(T1),或從1.5V切換到3.5V(T3)時所過渡的時間(編碼從OFF→ON or ON→OFF) | t1,t3 ≤ 3ms

| |||||||

(2) | Sliding noise 滑動雜訊 | Specified by the time of voltage level change drops to 1.5V and lower in code-ON area. When the sliding noise in code-ON area between t1 and t3 less than 2 ms, they are regarded as one linked signal. 電壓轉換到1.5V以下的ON區域時,在t1和t3區域之間所發生小於2ms的雜訊(t2)視爲連續的訊號. | t2 ≤ 2ms | |||||||

4.4 | Phase -difference 相位差 | Measurement shall be made with the specified shaft rotation speed as described in 360°/S constant speed. 軸以每秒360°的速度旋轉測定之。

Note : Above specification(4.4) is changeable. When operate by manual ,please check performance using actual circuit and knob. 注意事項: 手動操作時, 輸出波形會隨旋鈕大小及回轉速度 變化, 回路設計請實裝確認. | In ( fig.4) 如圖4所示. ΔT=0.25± 0.17T | |||||||

4.5 | Insulation resistance 絕緣電阻 | Measurement should be made under the condition that a voltage of 50V DC is applied between inpidual terminals and bushing. 測量時應在軸套與端子之間施加一50V DC的電壓. | Between inpidual terminals and bushing10MW Min. 端子与端子和軸套之間阻抗在10MW以上 | |||||||

4.6 | Dielectric strength 耐電壓 | A voltage of 50VAC should be applied for 1 minute between inpidual terminals and bushing(Leak current :1mA). 在各端子與軸套之間施加一50V AC ,1mA電壓測試1分钟 (漏電流: 1mA). | Without damage to parts, arcing or breakdown. 對零件無損傷, 跳弧及絕緣破壞現象. | |||||||

5 MECHANICAL CHARACTERISTICS機械性能

Item | Content 项目 | Test Condition 測試條件 | Specification 規格 | |

5.1 | Total rotational angle 全回轉角度 |

| 360°(Endless) 360°(連續) | |

5.2 | Rotational torque 回轉力矩 | Rotational speed旋轉速度: 60°/ Sec. | 30~200gf.cm | |

5.3 | Number position of detent 定位數 | Applied for with – detent type. 適用於具有定位點裝置的機種 | Refer to the separate product drawing參見成品圖 | |

5.4 | Terminal strength 端子強度 | A static load of 510gf should be applied to the tip of terminals for 10 seconds in any direction. 對端子的尖端從任何方向施以510gf的靜負荷10秒鐘

| Without damage or excessive looseness of terminals. Terminal bend is permitted. 端子無損壞或顯著鬆動,但是端子允許彎曲. | |

5.5 | Shaft wobble軸擺動 | A momentary load of 510gf should be applied at the point5mmfrom the tip of the shaft in a direction perpendicular to the axis of shaft. 從距離軸心頂端5mm處,以垂直於軸線的方向施以510gf的瞬間負荷測試. | 0.7 x L / 30(mm p-p less) L : measurement point from mounting surface of bushing L:軸套固定面到施力點之距離. | |

5.6 | Push-pull strength of shaft 軸心下壓-上拉強度 | Push and pull static load of 10Kgf should be applied to the shaft in the axial direction for 10 sec. (After installing) 從軸向施以10Kgf的靜負荷,下壓及上拉 10秒(實裝狀態). | Without damage or excessive play in shaft . No excessive abnormality in rotational feeling and electrical characteristics should be satisfied. 軸心無破損或過度鬆動。 軸心回轉無異常,且須符合原有電氣特性。 | |

5.7 | Shaft play in rotational wobble 軸心回轉晃動 | Measure with jip for rotational angle. 採用旋轉角度治具測試 | ≤ 3° | |

5.8 | Side thrust strength of shaft 軸心彎曲強度 | A load of 2Kgf.cm should be applied at the point5mmfrom the tip of the shaft in a direction perpendicular to the axis of shaft for 10seconds.(After soldered on the PCB) 從距離軸心頂端5mm處,以垂直於軸線的方向施以2Kgf.cm的靜負荷10秒鐘(成品焊接至電路板上後測試) | Without excessive play or bending in shaft . No mechanical abnormality . 軸心無彎曲,過度鬆動,無機械特性異常. | |

6 ENDURANCE CHARACTERISTICS耐久性能

Item | Content 项目 | Test Condition 測試條件 | Specification 規格 | |

6.1 | Rotational life 回轉壽命 | The encoder’s shall be rotated to 30,000 cycles at a speed of 600 per hour without electrical load, after which measurement shall be made .However, an interim measurement shall be made immediately after 5,000 cycles (1 cycle: rotate 360° CCW rotate 360 °CW) . 無任何電氣負荷下, 軸以每小時600回轉的速度下,持續進行30,000回轉.但是每進行5,000回轉時, 測定一次( 1回轉爲 360°往返一次)

| Fluttering: t1,t3≤5ms Sliding noise: t2≤3ms Detent feeling must remain (for detent-type only) . 接觸彈跳雜訊: t1,t3≤5ms 滑動雜訊: t2≤3ms 定位點必須保持原有停駐功能(僅適用於具有定位點的機種). | |

6.2 | Damp heat 耐濕特性 | The encoder should be stored at temperature of 40±2℃ ,with relative humidity of 90% to 95% for 240± 10 hour . in a thermostatic chamber, and then keep the encoder in a standard atmospheric condition for 1.5 hour before proceed the measurement. 編碼器測試前須先在溫度爲40±2℃,相對濕度爲90%~95%的恒溫容器中放置240±10小時,然後再置於常溫常濕的環境中1.5小時. | Specification in clauses 4.1~4.6 and 5.1~5.3 must be satisfied. 必須符合4.1~4.6和5.1~5.3條款的規定. | |

6.3 | Dry heat 耐熱特性 | The encoder should be stored at temperature of 85±3℃ for 240± 10 hour . in a thermostatic chamber, and then keep the encoder in a standard atmospheric condition for 1.5 hour before proceed the measurement. 編碼器測試前須先在溫度爲85±3℃的恒溫容器中放置240±10小時,然後再置於常溫常濕的環境中1.5小時. | Specification in clauses 4.1~4.6 and 5.1~5.3 must be satisfied. 必須符合4.1~4.6和5.1~5.3條款的規定. | |

6.4 | Cold 耐寒特性 | The encoder should be stored at temperature of -40±3℃ for 240 ± 10 hour . in a thermostatic chamber, and then keep the encoder in a standard atmospheric condition for 1.5 hour before proceed the measurement. 編碼器測試前須先在溫度爲-40±3℃的恒溫容器中放置240±10小時,然後再置於常溫常濕的環境中1.5小時. | Specification in clauses 4.1~4.6 and 5.1~5.3 must be satisfied. 必須符合4.1~4.6和5.1~5.3條款的規定. | |

6.5 | Free falling 墜落特性 | Measurement should be made by packing the encoder with vinyl package then dropped from60cmheight to the concrete floor. 將編碼器以乙烯類材料包裝,由離地面60cm的高度,成自由落體落至混凝土地面,再進行量測。

| No excessive deformation or damage(except the deformation of terminals). Specification in clauses 4.1~4.6 and 5.1~5.3 must be satisfied. 無過度變形或損壞(端子變形例外)。 必須符合4.1~4.6和5.1~5.3條款的規定. | |

6.6 | Vibration 耐震特性 | Following vibration should be applied to the encoder, after that the measurement should be made. The vibration frequency ranged from 10Hz to 55Hz and return to 10Hz, it should be transverse in 1 minute. With1.5mmamplitude. This motion shall be applied for a period of 2 hours in each of 3 mutually perpendicular axes ( a total of 6 hour) 做10Hz ~55Hz ~10Hz的變化震動試驗(1周期1分/振幅1.5mm)X、Y、Z每一軸向震動2小時(共計6小時)。 | Specification in clauses 4.1~4.6 and 5.1~5.3 must be satisfied. 必須符合4.1~4.6和5.1~5.3條款的規定.

| |

7 PUSH SPECIFICATION 按壓開關規格書

7.1 ELECTRICAL CHARACTERISTICS電氣特性

Item | Content 项目 | Test Condition 測試條件 | Specification 規格 | |||

7.1.1 | Contact resistance 接觸阻抗 | Measurement by the 5V DC / 1mA . 以5V DC / 1mA測試。

| ≤100mW | |||

7.1.2 | Chattering 接觸彈跳 | Switch is operated at the rate of 1 cycle/ sec. One cycle is OFF →ON→OFF)的迴圈。 | ≤10ms | |||

7.1.3 | Insulation resistance 絕緣電阻 | Measurement should be made under the condition that a voltage of 50V DC/1mA is applied between inpidual terminals and bushing. 測量時應在軸套與端子之間施加一50 DC/1mA的電壓. | Between inpidual terminals and bushing10MW Min. 端子與軸套之間阻抗在10MW以上 |

| ||

7.1.4 | Dielectric strength 耐電壓 | A voltage of 50VAC/1mA applied for 1 minute , or a voltage of 60V AC / 1mA applied for 2 sec. between inpidual terminals and bushing(Leak current :1mA). 在各端子與軸套之間施加一50V AC ,1mA電壓測試1分鐘,或外加60V AC / 1mA電壓測試2秒鐘,(包括漏電流測試). | No damage to parts, arcing or breakdown. 對零元件沒有任何的弧穿破裂、故障現象發生。 |

| ||

7.2 MECHANICAL CHARACTERISTICS機械特性

7.2.1 | Contact arrangement 開關回路接點數 | S.P.S.T(PushON) 單極單投(Push ON) |

7.2.2 | Switching stroke開關移動量 |

|

7.2.3 | Activating force作動力 | 400~600gf.cm |

7.3 ENDURANCE CHARACTERISTICS耐久性能

Item | Content 项目 | Test Condition 測試條件 | Specification 規格 | |

7.3.1 | Operation life 操作壽命 | Switch operation life should be tested for 20,000 times at a speed of 500 times per hour without electrical load. However, an intermediate measurement should be made 5,000 times . 無任何電氣負荷下, 軸以每小時500次的速度下,持續進行20,000次.每進行5,000次時, 測定一次 | ≥20,000 times Switch contact resistance : ≤200 MW Specification in clauses 4.1~4.6 and 5.1~5.3 must be satisfied. 开关寿命: 20,000次以上 开关接触阻抗: 必須符合4.1~和5.1~5.3條款的規定. | |

8 SOLDERING CONDITION耐焊錫條件

Item | Content 项目 | Test Condition 測試條件 | Specification 規格 | |

8.1 | Manual soldering 手工焊錫 | Bit temperature of soldering iron : 300 ± 10°Cor less Application time of soldering iron : within 3 s. 溫度300 ± 10°C以下,時間3秒以內. |

| |

8.2 | Dip soldering 自動焊錫 | Printed wiring board :Both-sided copper clad laminate board with thickness of1.6mm 使用基板:t=1.6mm的雙面銅泊積層板 Flux:Specific gravity : 0.82 or more. Flux shall be applied to the board using a bubble foaming type fluxer. The board shall be soaked in the flux bubble only to the 2/3 of its thickness. 助焊劑:發泡式助焊機內置比重0.82以上的助焊劑, 發泡面高度爲基板板厚的2/3. Preheating : Surface temperature of board:100°Cor less. Preheating time : within 2 min 預熱條件: 基板表面溫度100°以下, 時間2分鐘以內. Soldering: Solder temperature :≥265°C 焊錫爐條件:溫度260±5°C , 時間5±1秒. Apply the above soldering process for 1 or 2 times. 以上工程以1次或2次爲宜. | There shall be no deformation or cracks in molded part. No excessive abnormality in rotational feeling. 不可發生絕緣體變形, 破損以及感觸異常.

| |

9 SOLDERING CONDITION耐焊錫條件

Item | Content 项目 | Test Condition 測試條件 | |||

9.1 | Flux penetrating 焊劑滲入 | Please avoid soldering on upper (component side surface ) of the PC board as shown below. 請避免焊錫作業時將焊劑滲入(元件側面的表面)PCB的表面.請參考圖3.

|

9.2 | Clean 清除汙物 | Please avoid cleaning of PC board because the flux used during the dip soldering process may enter the encoder and cause poor contact. 請清除汙物,因爲基板浸入焊劑作業過程中,汙物會滲入編碼器內部,造成接觸不良. |

10 PRECAUTIONS IN USE使用前注意事項

Item | Content 项目 | Test Condition 測試條件 | |||

10.1 | Storage environment 存儲環境 | Storage in high temperature, high humid and corrosive gas environment should be avoided. 請避免存放于高溫、高濕及具腐蝕性的場所。 | |||

10.2 | Pulse count operation 脈衝計數操作 | For the pulse count operation , care should be taken with operation speed, sampling time and masking time etc. 必須注意脈衝計算處理的動作方式。注意操作速度、取樣時間及遮罩時間等。 | |||

10.3 | Application 應用設計 | For product of with-detent type , detent position is always aligned with A-OFF phase , therefore, it is strongly recommended that use A output signal for the reference of the software design. 附定位點的産品,每個定位點停駐位置爲A輸出訊號OFF狀態,因此在産品應用的軟體設計上,最好以A相位爲參考基準。 | |||

10.4 | RC Filter circuit RC濾波電路

| For the implementation of the pulse count or menu control , always use the RC filter circuit shown as below. 在脈衝計算或選項控制的運用時,盡可能採用下圖所示的RC濾波電路過濾雜訊。

| |||

10.5 | Waterproofing 防水設計 | Care must be taken not to expose this product to water or dew to prevent possible problem in pulse output waveforms. 本産品的本體必須避免直接接觸到水或露水,以避免影響到輸出波形,造成輸出異常。 | |||

10.6 | Radial Pressure 徑向壓力 | To avoid excessive radial pressure to the shaft , for best performance consideration, care must be taken when choosing knob for the product. 本産品的主軸無法承受過度的徑向壓力,因此在選用旋鈕時,必須考慮軸套的側向壓力,以確保本産品的機能。 | |||

10.7 | Impact 撞擊 | Excessive impact force may decrease the performance or even cause damage o the product. For best performance consideration, care must be taken to avoid excessive impact force. 本産品的主軸無法過度的撞擊力,爲確保本産品的機能請避免過度的撞擊。 |