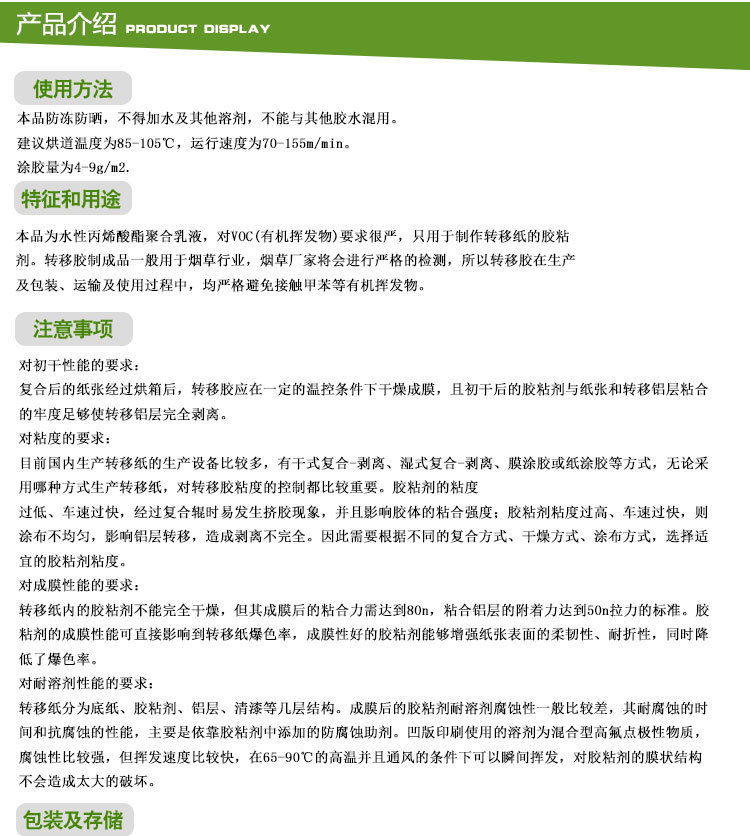

特征和用途/ Features

本品为水性丙烯酸酯聚合乳液,对VOC(有机挥发物)要求很严,只用于制作转移纸的胶粘剂。转移胶制成品一般用于烟草行业,烟草厂家将会进行严格的检测,所以转移胶在生产及包装、运输及使用过程中,均严格避免接触甲苯等有机挥发物。

This product is a water-based acrylic emulsion polymerization of VOC (volatile organic compounds) requirements are very strict, only for the production of adhesive transfer paper. Finished goods are generally used for the transfer of the tobacco industry, rubber, tobacco manufacturers will conduct rigorous testing, so the shift in the production of plastic and packaging, transport and use, strictly avoid contact with toluene and other volatile organic compounds.

注意事项/ Notes

对初干性能的要求:

复合后的纸张经过烘箱后,转移胶应在一定的温控条件下干燥成膜,且初干后的胶粘剂与纸张和转移铝层粘合的牢度足够使转移铝层完全剥离。

对粘度的要求:

目前国内生产转移纸的生产设备比较多,有干式复合-剥离、湿式复合-剥离、膜涂胶或纸涂胶等方式,无论采用哪种方式生产转移纸,对转移胶粘度的控制都比较重要。胶粘剂的粘度

过低、车速过快,经过复合辊时易发生挤胶现象,并且影响胶体的粘合强度;胶粘剂粘度过高、车速过快,则涂布不均匀,影响铝层转移,造成剥离不完全。因此需要根据不同的复合方式、干燥方式、涂布方式,选择适宜的胶粘剂粘度。

对成膜性能的要求:

转移纸内的胶粘剂不能完全干燥,但其成膜后的粘合力需达到80n,粘合铝层的附着力达到50n拉力的标准。胶粘剂的成膜性能可直接影响到转移纸爆色率,成膜性好的胶粘剂能够增强纸张表面的柔韧性、耐折性,同时降低了爆色率。

对耐溶剂性能的要求:

转移纸分为底纸、胶粘剂、铝层、清漆等几层结构。成膜后的胶粘剂耐溶剂腐蚀性一般比较差,其耐腐蚀的时间和抗腐蚀的性能,主要是依靠胶粘剂中添加的防腐蚀助剂。凹版印刷使用的溶剂为混合型高氟点极性物质,腐蚀性比较强,但挥发速度比较快,在65-90℃的高温并且通风的条件下可以瞬间挥发,对胶粘剂的膜状结构不会造成太大的破坏。

The early dry performance requirements:

composite of paper after the oven, transfer adhesive should be at a certain temperature-controlled conditions dry film, and after the beginning of the dry adhesive with adhesive paper and transfer the fastness of the aluminum layer of aluminum is sufficient to transfer layer is completely stripped.

Viscosity requirements:

the current domestic production of transfer paper production equipment more, there are dry compound - peel, wet composite - peeling, adhesive film or paper glue, etc. Either way production using transfer paper, glue on transfer viscosity control are more important. Viscosity of the adhesive is too low, excessive speed, after the composite roll extrusion plastic phenomenon prone and affect the adhesive strength of colloids; adhesive viscosity is too high, excessive speed, the coating uneven impact of the transfer of the aluminum layer, resulting in peeling incomplete. Therefore, depending on the needs of complex ways, drying method, coating method, choose the

appropriate adhesive viscosity.

Performance requirements of the film:

the adhesive transfer paper can not be completely dry, but after the film adhesion required to achieve 80n, bonded aluminum layer adhesion to pull 50n standard. Adhesive film forming

properties of the transfer paper can directly affect the color burst rate, good film-forming properties can enhance the flexibility of the adhesive, folding the paper surface, while reducing the rate of the color burst.

Requirements for solvent resistance:

transfer paper into the end of paper, adhesives, aluminum layer, varnish layers structure. Adhesive solvent resistance after film formation is generally poor, and its corrosion resistance and corrosion resistance of time, mainly by adding adhesive corrosion additives. The solvent used is a mixed-type gravure fluorine point polar substances, corrosive relatively strong, but relatively fast evaporation rate, can instantly volatilize at a high temperature of 65 -90℃ and ventilation conditions, the adhesive film-like structure that does not cause too much damage.

使用方法/ Use Methods

本品防冻防晒,不得加水及其他溶剂,不能与其他胶水混用。

建议烘道温度为85-105℃,运行速度为70-155m/min。

涂胶量为4-9g/m2。

This product antifreeze sunscreen, water and other solvents shall not be mixed with other glue.

Recommended bake temperature of 85-105 ℃, running at 70-155m/min.

Adhesive capacity of 4-9g/m2.