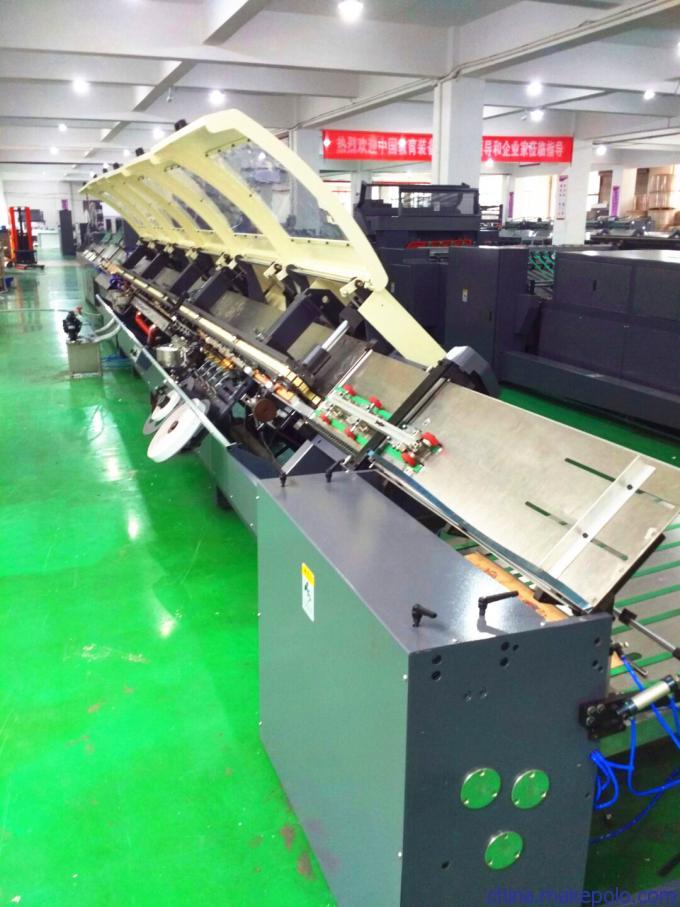

胶装软抄笔记本机器设备

性能与特点:

本机采用双电脑控制,光电跟踪,气液联动,人机界面触摸屏操作,水墨柔版印刷等高新技术,双电脑可同时联机操作,两个电脑也可分别单独操作自己控制的部分部套。水墨柔版印刷既环保又科学。本机操作界面简便直观,结构合理,性能可靠,调整方便。该联动生产线是将卷筒纸放卷,经高速柔版印刷,立线,分割,折页,纵向分切,数页堆纸,输送,整纸,铣槽,上侧胶,上背胶,自动封面供给,书芯封面粘合,经二次托实夹紧包本,自动落本经输送带进三面切一次性有机结合完成。此设备从原纸进入后直接成品出来,由3人操作完成,每天可生产5-8吨卷筒纸,是目前薄本行业热熔胶无线装订本大批量生产最理想的设备。

Function and features:

The machine adopts high and new technology such as double computer control, photoelectric tracking, gas-liquid interaction, human-machine interface touch screen operation and water ink flexographic printing. The double computer control systems can be operated at the same time or separately. Two systems control different parts and units. The water ink flexographic printing is environmental protection. The machine operation system is simple and intuitive interface, reasonable structure, reliable performance, easy to adjust.

The main processes of the machine are reel paper unwinding, high speed flexographic printing, vertical lines, cutting, folding, separate cutting, counting and overlapping, transferring, collating, milling groove, gluing top, gluing back, automatic cover feeding, cover casing, pressing and creasing and automatic finished book output. The machine is equipment for hot glue thin book batch production.

'