ECMT-100 全自动水平连续发泡生产线 艾立克海绵发泡线

ECMT-100 全自动水平连续发泡生产线 艾立克海绵发泡线

主要用途:

本设备主要适用于8-70kg/m3密度范围的软质聚氨脂泡绵生产,采用了自动化程度高、掌握更加灵活的人机界面控制系统,用户可以储存7种不同的配方,也可以随时对配方进行调整或更改,并可通过互联网进行远程控制,使生产成本的控制更为科学、直观。可以生成出各种理想的家私绵、鞋材绵、胸围绵、电子绵,以及适应于包装、制衣和汽车工业用的各种泡绵。(本机有:自动手控和自动人机界面两种配置可供选择)

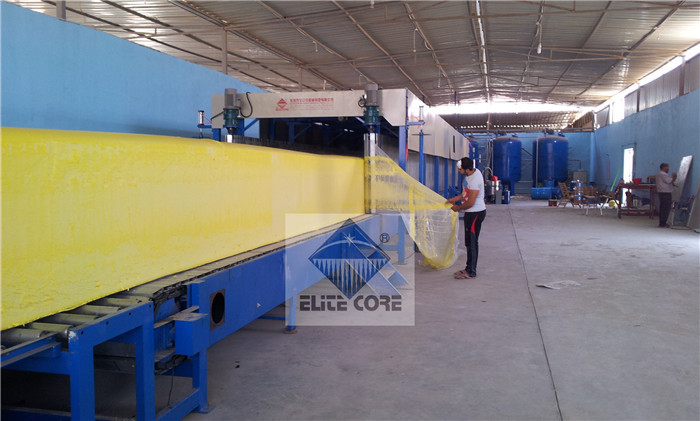

Process: All the P.U. chemicals are first mixed together in a mixing chamber & then taken into a metal trough where the initial reaction takes place. The rising foam then passes from the top of the trough on to a variable width fall plate, which then leads the expanding foam block along a metal slat conveyor for further expansion.

Outputs: The machine is delivers a maximum of 350kg per minute.

Metering System: There are seven metering systems in all. All metering system are equipped with world class AC motors, AC variable speed drives, Viking, U.S.A made internal gear pumps (for very low slippage), pressure gauges & Recirculation network to ensure high class quality product.

Foaming Tunnel & Conveyor: The tunnel construction forms a complete enclosure around the foam slab with top plates, side walls & conveyor slats. The conveyor motor is also equipped with AC speed drive. Side walls can be adjusted from 0.98m~2.4 m. The length of the conveyor is 16.9 meters.

Trough & Fall Plate: The Trough & fall plate section can be adjusted height wise at various levels to ensure more flattop blocks & is equipped with required motors & gearboxes.

Paper Feed & Rewind : This is a 2-paper system. The bottom paper feed reel is mounted in front of the foaming platform & is equipped with unwinding motor for automatic operation. Rewinding of the side papers is at the other end of the tunnel & the rewinding speed is self –adjustable to synchronize with the conveyor speed.

Control Panels: This is attached at a convenient position on the foaming platform, It is equipped with necessary electronics, flow meters, pressure gauges & AC variable speed drives.

技术参数

最大吐出量: Max.Output Capacity: | 200~350公斤/分钟(连续型) 200~350kg/min(Continuous Type) |

混合头总功率: Mixer Total Power: | 37kw |

最大搅拌速度: Max.Mixing Speed: | 2500~6000转/分钟 2500~6000r/min |

发泡形式 Foaming Type: | 采用溢流槽或喷头方式. Trough & Sprayer |

组份: Save Formular Q.T.Y.: | 13组份 13 Groups. |

发泡尺寸: Foaming Size: | W2300mm*H1300mm(宽度可调) W2300mm*H1300mm(Width Adjustable) |

控制系统: Control System: | PLC 数控触摸屏系统(台湾品牌) 和 电控柜系统 PLC Digital Touch Screen(Made In TaiWan) And Electirc Control System. |

PPG 罐: PPG Tank: | 5吨位*1套 5Ton*1Set. |

POP罐: POP Tank: | 5吨位*1套 5Ton*1Set. |

PPG+粉 罐 PPG+CACO3 Tank | 5吨位*1套 5Ton*1Set |

防火油罐 Fire-Retardard Tank | 1吨位*1套 1Ton*1Set |

TDI 罐 TDI Tank: | 4吨位*1套 4Ton*1Set. |

MC 罐: MC Tank: | 1吨位*1套 1 Ton*1Set. |

硅油罐+水罐: Silicone +Water Tanks: | 100升*2套 100L*2Sets |

T-9罐+胺罐+色料罐(A.B.C): T-9+Amine+Color (A.B.C): | 50升*5套 50L*5Sets |

侧连板尺寸: Side Wall Size: | L18m*H1200mm |

跌落板: Fallplate: | L7m*W0.98~2.4m(宽度可调) L7m*W0.98~2.4m(Adjustable) |

发泡平台: Foaming Platform: | L2000mm*W3000mm*H700mm |

输送线 Conveyor Line: | L18.1m |

侧纸/底纸输送+收卷系统 Side/Bottom Paper Feed & Rewind System: | 2套 2Sets. |

走廊: Walkway: | W500mm*L18m |

气阀: Air Valves | 欧洲标准 Euro Standard |

冷热水一体机: Chiller(Both Cooling & Heating System): | 1套*1.5HP(台湾品牌) 1Set*1.5HP(Made In TaiWan) |

边膜提升系统: Side Film Lifting System: | 1套 1Set. |

发泡密度范围: Foaming Density Range: | 8~70公斤/立方 8~70kg/Cubicmeter. |

裁断机: Match With Block Cutter: | 1套 1Set. |

机械总功率: Total Motor Power: | 大约125KW Approx 125kw. |

空气压缩机: Air Compressor: | 配7.5KW(10HP)*1台 Match With 7.5KW(10HP)*1Set |

机械净重: Machine N.W.: | 约60吨 Approx 60Ton |

安装占地面积: Floor Space Required: | L45m*W5m*H4.5m. |