三维立体玻纤织物3D GLASS FABRIC

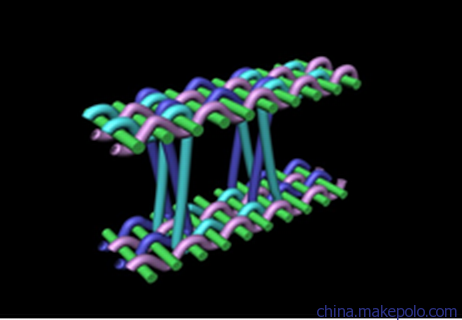

三维立体玻纤织物是采用100%无碱玻璃纤维纱运用现代最新的双剑杆织造技术开发的一种高性能立体织物,其结构基础是构成表层的经、纬纱和连接两个表层并形成芯部的Z向纤维,三维中空玻纤织物的织造高度范围为3-25mm,空间形态可以根据复合材料的使用要求任意设计为“8”、“X”、“V”字形等。

3D glass fabric is woven out of 100% E-glass fiber,.This structure consists of two decklayers formed by warp and weft direction fibers and Z direction fibers which interconnect both decklayers. The typical structure of vertical piles can be recognized by the 8-shaped piles in warp direction. Other shapes of vertical piles, such as X-shape and V- shape can be realized too. The height between two decklayers (Z direction) can be designed from 3mm to 25mm in order to meet different needs.

三维立体玻纤织物的规格Datasheet

规格(Type) |

| 3 | 3.5(储罐专用) | 5 | 8 | 10 | 12 | 15 | 18 | 20 |

芯层厚度 (Core Thickness) | mm | 2.5 | 3 | 4.5 | 7.5 | 10.0 | 12.0 | 15.0 | 18.0 | 20.0 |

面层厚度 (Decklayer Thickness) | mm | 0.25 | 0.25 | 0.25 | 0.25 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 |

织物重量 (Fabric Weight) | g/m2 | 650 |

630 | 820 | 1090 | 1260 | 1320 | 1550 | 1710 | 1830 |

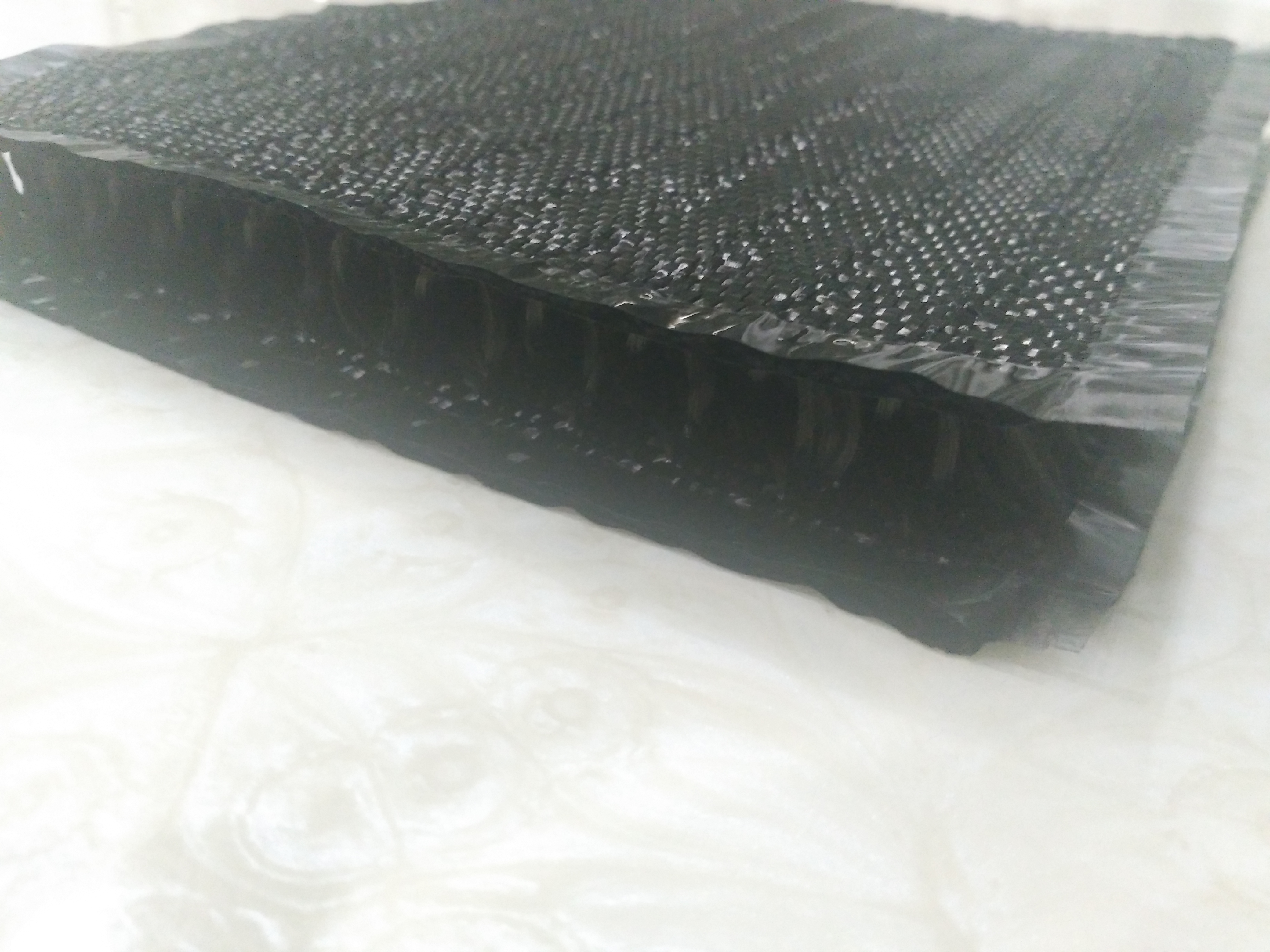

立体复合板材3D Composites

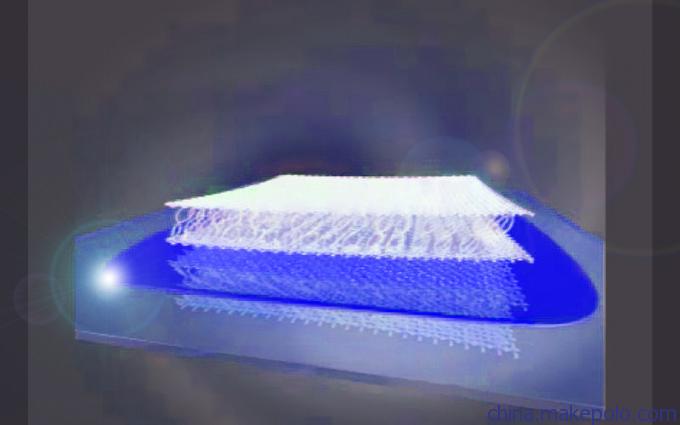

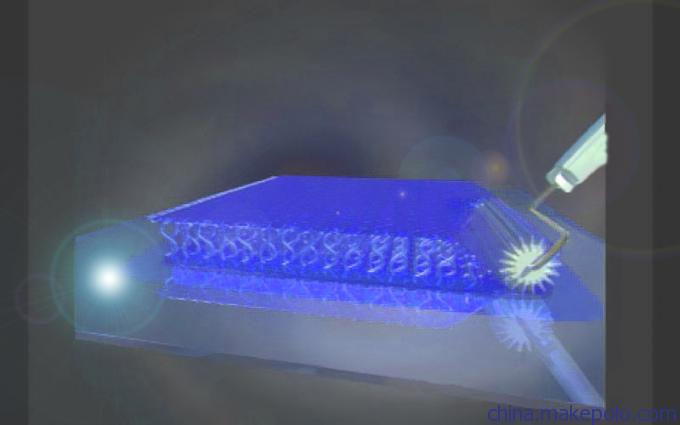

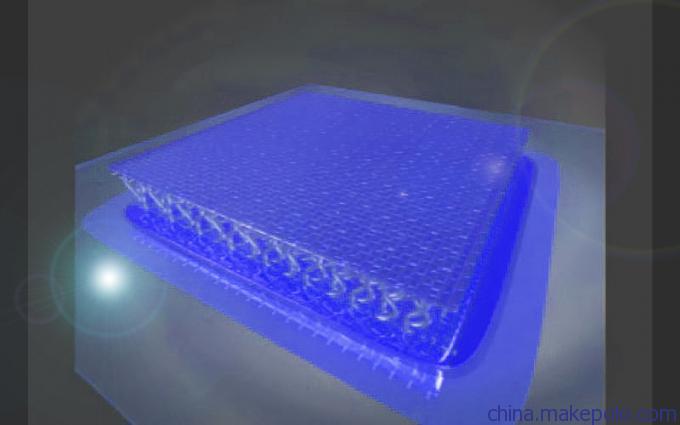

三维立体玻纤织物可以瞬间吸收树脂,Z向纤维在“毛细作用”效果下使织物自动成型到设计高度。其复合材料的整体中空三明治结构,克服了传统蜂窝、泡沫芯材等夹层复合材料易分层、耐冲击性能差的缺点,可以广泛用于轨道交通、船艇、航空、航天、建筑、双层储罐等领域。

When the fabric is impregnated with a thermoset resin, the fabric absorbs the resin and rises to the preset height. Owing to the integral structure, composites made of 3d sandwich woven fabric boast superior resistance against delamination to traditional honeycomb and foam cored materials.

规格参数 Datasheet

规格(Type) | 单位 | 3 | 3.5 | 5 | 8 | 10 | 12 | 15 | 18 | 20 |

芯层厚度 (Core Thickness) | mm | 2.5 | 3.0 | 5.0 | 8.0 | 10.0 | 12.0 | 15.0 | 18.0 | 20.0 |

面层厚度 (Decklayer Thickness) | mm | 0.25 | 0.25 | 0.25 | 0.25 | 0.35 | 0.35 | 0.35 | 0.35 | 0.35 |

重量 (Weight) | g/m2 | 1520 | 1450 | 1720 | 1920 | 2950 | 3100 | 3280 | 3480 | 3580 |

材料优势:Advantages:

1、轻质高强,比强度、比模量高;Light weight but high strength;

2、三维机织整体成型,抗分层、剥离;Great resistance against delamination;

3、结构可设计性强(高度、重量、纤维类型、空间形态等);High design-versatility;

4、立体结构可填充、预埋、发泡(泡沫、探头、导线等);Space between both decklayers can be multi-functional (embedded with sensors and wires or infused with foam);

5、易于复合、贴膜仿形,复合效率高;Simple and effective lamination process

6、保温、隔音、阻燃、透波 Thermal and sound insulated.; Fire retardant; Wave transmittable.

立体玻纤复合材料性能Datasheet of 3D Composites

项目 Subjects | 标准 Test Method |

| 3 | 5 | 8 | 10 | 12 | 15 | 18 | 20 |

导热系数 (Thermal Conductivity) | DIN 52616 (N) | W/mk | 0.06 | 0.06 | 0.06 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

隔热性能 (Thermal Resistance) | DIN 52616 (N) | m2k/w | 0.05 | 0.08 | 0.12 | 0.13 | 0.15 | 0.18 | 0.21 | 0.24 |

拉伸强度 (Tensile Strength) | ASTM D1689/579(N) | Mpa | 282 | 305 | 317 | 324 | 333 | 341 | 352 | 361 |

208 | 216 | 224 | 228 | 232 | 239 | 245 | 238 | |||

平压强度 (Flatwise Compression) | ASTM 365(N) | Mpa | 8.7 | 5.1 | 4.5 | 2.6 | 2.4 | 2.2 | 1.9 | 1.3 |

7.5 | 3.9 | 3.1 | 2.3 | 2.0 | 1.9 | 1.4 | 0.9 | |||

双层剪切强度 (Shear Strength) | ASTM 273(N) | Mpa | 3.0 | 2.8 | 2.9 | 2.7 | 2.5 | 2.1 | 1.8 | 1.3 |

1.7 | 1.4 | 1.2 | 1.0 | 1.0 | 0.8 | 0.6 | 0.5 | |||

双层剪切模量 (Shear Modulus) | ASTM 273(N) | Mpa | 73 | 62 | 56 | 47 | 44 | 39 | 31 | 26 |

24 | 31 | 27 | 24 | 21 | 18 | 19 | 18 | |||

四点弯曲强度 (Bending Strength) | ASTM 393 (N) | Mpa | 116 | 111 | 107 | 104 | 97 | 92 | 89 | 85 |

51 | 48 | 45 | 42 | 39 | 35 | 37 | 34 |

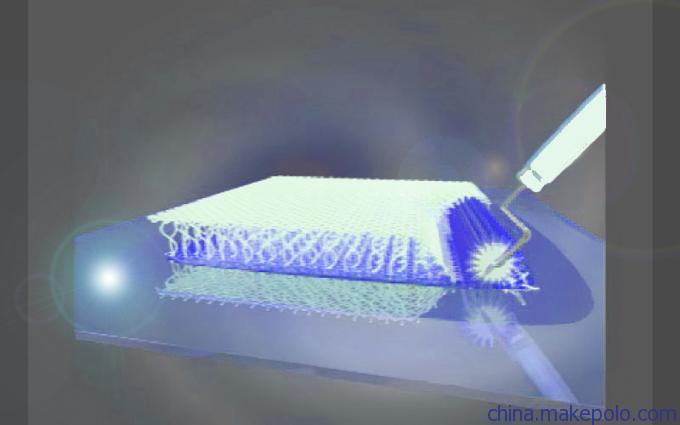

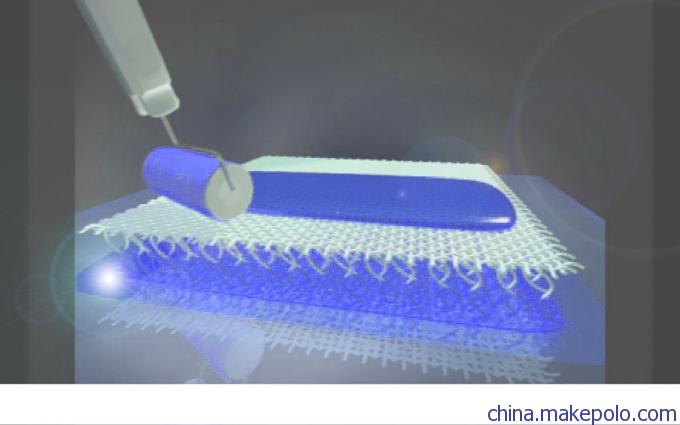

成型工艺示意图

立体玻纤复合材料的应用 Application of 3D composites

轨道交通 Transportation

利用立体玻纤复合材料具有优异的强度/重量比、整体抗分层、保温、隔音、阻燃、易于贴模成型的优点开发了系列高铁产品,应用在高速列车导流罩、高速列车窗下墙板、高速列车车顶板、地铁及高速列车车门等。

1、 高速列车导流罩

2、高速列车窗下墙板

. Interior wall panels for high-speed trains

3、高速列车车门 Train Doors

新能源客车板材

立体玻纤复合材料比传统客车地板竹胶板及车用板材具有制备效率高、减重显著、隔音隔热、耐腐蚀、安全系数高等突出优势。

Being lighter, safer and stronger, 3D composites are good substitute for traditional bamboo plywood or honeycomb to build bus parts with high e efficiency..

新能源客车电池箱及隔板

建筑(结构―功能材料) Building and Construction

立体复合材料增强超薄石材板是以立体玻纤复合材料为基材,通过与3—5mm厚石材薄板一次粘接成型,克服了天然石材固有的重量大、易破裂等缺点,具有重量轻、强度高、抗污染能力强、容易控制色差、施工方便、制造成本低、隔音、隔热、耐老化效果好,可广泛应用于建筑物内外墙,吊顶,地板等建筑装饰领域,是一种高科技新型绿色环保节能装饰产品。

With better mechanical properties and thermal and sound insulation on a lighter weight base, 3d sandwich composites are ideal substitute for traditional honeycomb materials when adhered to 3-5mmthick stone slices (e.g. marble & granite). This advanced composite material has been increasingly accepted in the manufacture of interior and exterior wall covers, partitioning panels as well as roofing and flooring systems etc.

立体增强透光超薄玉石板

双层储罐Double Wall Storage Tanks

立体玻纤复合材料特殊的贯通夹层结构可以预埋监控探头、感应器、导线等元件,用立体玻纤复合材料作为储罐的包覆层,可以有效的监控储罐内液体的泄漏和使用情况,解决了地埋式储罐迅速检测泄露难题,有效的预防罐体泄漏对空气、土壤、地下水的污染,是一类环保功能型产品。

3D sandwich composites are ideal core material for double-wall tanks. The space between two decklayers enables the installation of monitoring devices which can effectively detect the leakage of liquid inside the tanks.

立体玻纤增强材料特殊的贯通夹层结构可以灌注液体,抽真空或预埋监控探头、感应器、导线等元件。用立体玻纤增强材料作为储罐的中间层(中间层厚度从2mm 至10mm 均可设计),可以有效的监控储罐内液体的泄漏和使用情况,解决了地埋式储罐迅速检测泄露难题,有效的预防罐体泄漏对空气、土壤、地下水的污染,是一类新型环保功能型产品。

The internal liner in reinforced 3D glass fiber material can be perfused with liquid, evacuated and embedded monitoring probe, sensors, wire etc components. The reinforced 3D glass fiber material used as interlinings of storage tanks (the thickness of middle layer from 2 -10 mm all can be designed.) can effectively monitored the leakage and use situation of liquid in storage tank, have solved the issue of rapidly detect leak in the USTs,and effectively prevent the air, soil and groundwater from pollution. So it is a kind of new functional and environmental products.