INCOLOY® alloy 028 (UNS N08028/W. Nr. 1.4563) is

a highly alloyed austenitic stainless steel offering

resistance to a variety of corrosive media. By virtue of

its contents of chromium and molybdenum, the alloy

offers resistance to both oxidizing and reducing acids

and salts. The presence of copper increases its

resistance to sulfuric acid. The alloy is used in the

chemical and petrochemical processing industry. Alloy

tubes are cold worked to high strength levels for

downhole service in moderately corrosive deep sour gas

wells.

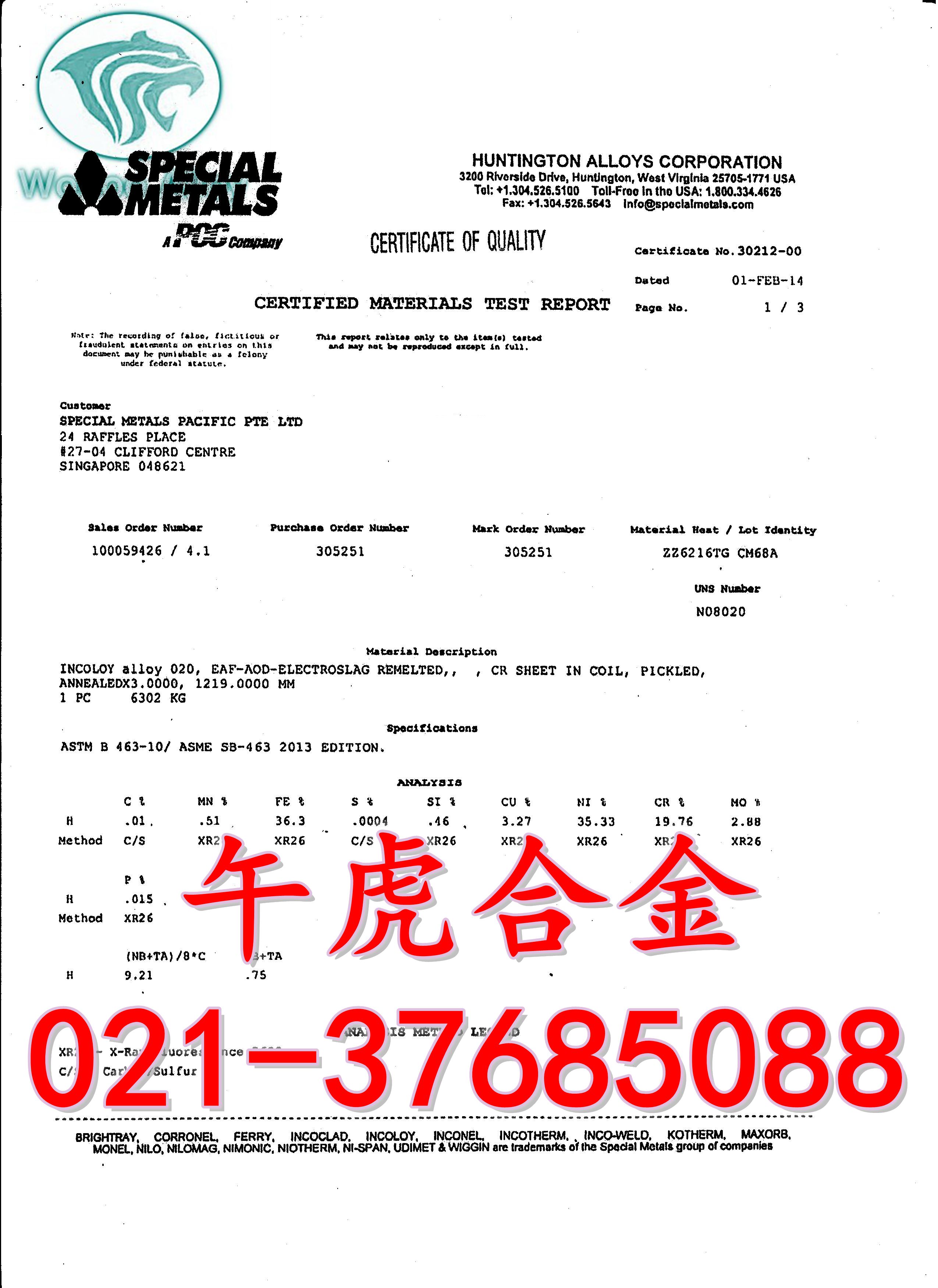

Table 1 - Limiting Chemical Composition, %

Nickel ..........................................................................30.0-34.0

Chromium....................................................................26.0-28.0

Molybdenum ...................................................................3.0-4.0

Iron ...............................................................................Balance*

Carbon......................................................................0.030 max.

Silicon .........................................................................1.00 max.

Manganese .................................................................2.50 max.

Phosphorus ..............................................................0.030 max.

Sulfur ........................................................................0.030 max.

Copper ............................................................................0.6-1.4

Publication Number SMC-073

Copyright © Special Metals Corporation, 2003 (Oct 03)

INCOLOY and INCONEL are trademarks of the

Special Metals Corporation group of companies.

*Reference to the ‘balance’ of a composition does not guarantee this

is exclusively of the element mentioned but that it predominates and

Physical Constants and Thermal others are present only in minimal quantities.

Properties

Table 2 - Physical & Thermal Properties

Density, lb/in3.......................................................................0.29

g/cm3........................................................................8.0

Specific Heat (32-212°F), Btu lb °F...................................0.105

(0-100°C), J/kg °C .........................................450

Coefficient of Expansion, 10-6 in/in °F (microm/m °C)

70-200°F (21-93°C) ..............................8.3 (15.0)

70-500°F (21-260°C) ............................8.8 (15.9)

70-800°F (21-427°C) ............................9.3 (16.8)

Thermal ConductivityA, Btu in/ft2 h °F ...................................66

W/m °C........................................................11.4

Electrical ResistivityA, ohm circ mil/ft ...................................594

micro ohm m ................................................0.99

Young’s ModulusA, 103 ksi...................................................29.0

GPa................................................................200

A

Annealed product, tested at room temperature

Mechanical Properties

Table 3 - Typical Mechanical Properties

(Annealed)

Tensile Strength, ksi ...............................................................73

MPa ..........................................................500

Yield Strength (0.2% Offset), ksi ............................................31

MPa .......................................214

Elongation, % .........................................................................40

Hardness (HRB).................................................................80-90

(Cold Worked)

Tensile Strength, ksi .............................................................130

MPa ..........................................................896

Yield Strength (0.2% Offset), ksi ..........................................110

MPa .......................................758

Elongation, % .........................................................................15

Hardness (HRC).............................................................33 max.

The data contained in this publication is for informational purposes only and

may be revised at any time without prior notice. The data is believed to be

accurate and reliable, but Special Metals makes no representation or warranty of

any kind (express or implied) and assumes no liability with respect to the

accuracy or completeness of the information contained herein. Although the

data is believed to be representative of the product, the actual characteristics or

performance of the product may vary from what is shown in this publication.

Nothing contained in this publication should be construed as guaranteeing the

product for a particular use or application.