产品名称:254SMO/UNS S31254

石化设备中的波纹管254SMO/UNS S31254高耐腐蚀

国际通称:254SMO、UNS S31254、W.-Nr. 1.4547、F44、NAS 185N、00Cr20Ni18Mo6CuN、6Mo

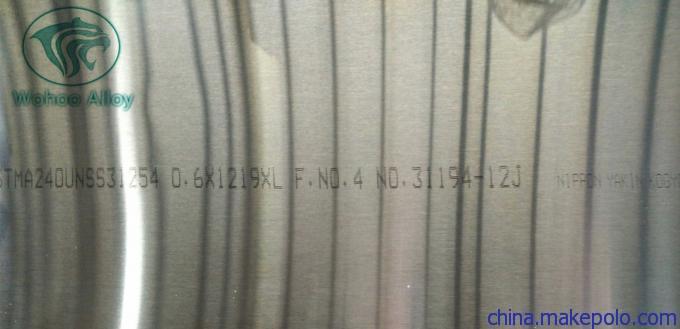

执行标准:ASTM A240/ASME SA-240、ASTM A276、ASTM A182/ASME SA-182、ASTM A312/ASMES A312

主要成分:碳(C)≤0.02,锰(Mn)≤1.00,镍(Ni)17.5~18.5,硅(Si)≤0.8磷(P)≤0.03,硫(S)≤0.01,铬(Cr)19.5~20.5,铜(Cu)0.5~1.0,钼(Mo)6.0~6.5, 氮(N) 0.18~0.22

物理性能:254SMO密度:8.24g/cm3, 熔点:1320-1390 ℃,磁性:无

热处理:1150-1200℃之间保温1-2小时,快速空冷或水冷。

机械性能:抗拉强度:σb≥655Mpa,屈服强度σb≥310Mpa:延伸率:δ≥35%,硬度:182-223(HB)

耐腐蚀性及主要使用环境:254SMO不锈钢是一种高耐腐蚀超级奥氏体不锈钢,针对卤化物和酸的环境而开发,广泛用于高浓度氯离子介质、海水等苛刻工况环境。在酸性介质的各种工业场合,特别是在含卤化物的酸中,254SMO要远远优于其它不锈钢,某些情况下可以和哈氏合金以及钛相媲美。较低的含碳量和高钼含量,使其具有较好的耐点腐蚀和耐缝隙腐蚀性能、优秀的耐晶间腐蚀能力,是一种高性价比不锈钢,在国内外化工、脱硫环保等领域广泛使用。

在纯硫酸中,254SMO比316普通型不锈钢具有大得多的抗腐蚀性。但在高浓度时与904L(NO8904)型不锈钢相比,254SMO的抗腐蚀能力则稍弱。在含有氯离子的硫酸中,254SMO具有最大的抗腐蚀力。由于可能会发生局部腐蚀和均匀腐蚀,所以316普通型不锈钢不能用于盐酸中,但是在一般温度下254SMO可以用于稀释的盐酸中。在边界线的以下区域内不必担心发生点腐蚀。但必须设法避免缝隙的存在。在氟硅酸中(H2SiF4)和氢氟酸(HF)中,普通的不锈钢的耐腐蚀范围是很有限的,而254SMO则能在相当宽的浓度和温度的范围内应用。

配套焊接材料及焊接工艺:254SMO的焊接选用高配625合金系列焊材,即ERNiCrMo-3焊丝,ENiCrMo-3焊条,焊材尺寸有Φ1.0、1.2、2.4、3.2、4.0,产地为:美国哈氏、美国SMC和德镍,焊接工艺及指导书欢迎来电索取。

库存情况:254SMO不锈钢板库存现货尺寸有0.5mm-18mm,棒材库存现货尺寸有Φ12mm-Φ250mm,管材管件及其他可根据客户要求定做。材料产地主要有日本冶金、日本新日铁住金和瑞典OUTOKUMPU。提供原厂材质证明书、报关单及原产地证明文件。

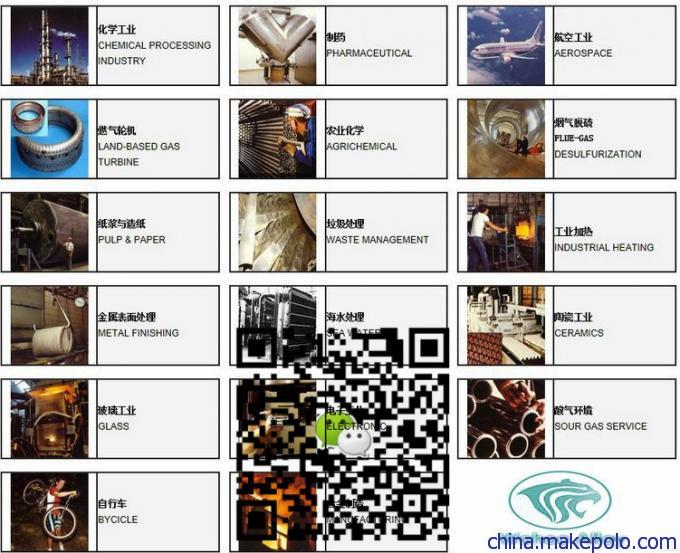

应用领域有:石油、石化设备,如石化设备中的波纹管,纸浆、造纸漂白设备,如纸浆蒸煮器、漂白设备、过滤洗涤器用的桶缸和压辊等,发电厂烟气脱硫装置,主要使用部位有:吸收塔的塔体、烟道、档门板、内件、喷淋系 统等,海上系统或海水处理,如电厂中用海水冷却的薄壁冷凝管道、海水淡化处理设备、即使 在海水可能不流动的设备中也可以应用,脱盐工业,如制盐或除盐设备,热交换器,尤其在有氯离子工作环境中的热交换器。

Product name: 254 smo/UNS S31254

International general information: 254SMO, UNS S31254, W. -nr.1.4547, F44, NAS 185N, 00Cr20Ni18Mo6CuN, 6Mo

Standard: ASTM A240/ASME sa-240, ASTM A276, ASTM A182/ASME sa-182, ASTM A312/ASMES A312

Main ingredients: carbon (C) 0.02 or less, manganese (Mn) of 1.00 or less, nickel (Ni) 17.5 ~ 18.5, silicon (Si) of 0.8 or less phosphorus (P) of 0.03 or less, sulfur (S) of 0.01 or less, chromium (Cr) 19.5 ~ 20.5, copper (Cu) 0.5 ~ 1.0, molybdenum (Mo) 6.0 ~ 6.5, the nitrogen (N) 0.18 ~ 0.22

Physical properties: 254 smo density: 8.24 g/cm3, melting point: 1320-1390 ℃, magnetic: no

Heat treatment: 1-2 hours between 1150-1200 ℃ heat preservation, air cooling or water cooling rapidly.

Mechanical properties: tensile strength: sigma b is greater than 655Mpa, yield strength sigma b is greater than 310Mpa: extension rate: delta is greater than 35%, hardness: 182-223 (HB).

Corrosion resistance and main use environment: 254 smo stainless steel is a kind of high corrosion resistant super austenitic stainless steel, in view of the halide and acid environment and development, widely used in high concentrations of chloride ions in the medium, water and other harsh working environment. In various industrial occasions of acidic media, especially in the acid containing halide, 254 smo is far superior to other stainless steel, in some cases comparable to that of hailin and titanium. Low carbon and high molybdenum content, make it has good resistance to pitting corrosion and crevice corrosion resistance, excellent intergranular corrosion resistant ability, is a kind of cost-effective stainless steel, widely used in chemical industry, the environmental protection in areas such as desulfurization at home and abroad.

In pure sulfuric acid, 254SMO is much more resistant to corrosion than 316 ordinary stainless steel. However, compared with 904L (NO8904) stainless steel in high concentration, the anti-corrosion capability of 254SMO is slightly weaker. In the sulfuric acid containing chloride ion, 254SMO has the largest anti-corrosive force. Because of local corrosion and uniform corrosion, 316 ordinary stainless steel can not be used in hydrochloric acid, but 254SMO can be used in dilute hydrochloric acid in general temperature. No corrosion is necessary in the following areas of the boundary line. But the gap must be avoided. In fluorosilicic acid (H2SiF4) and hydrofluoric acid (HF), the corrosion range of normal stainless steel is very limited, while 254SMO can be applied in a wide range of concentrations and temperatures.

Form a complete set of welding material and welding process, welding with high with 625 alloy series of 254 smo welding materials, namely ERNiCrMo - 3 wire, ENiCrMo - 3 welding rod, welding material size Φ 1.0, 1.2, 2.4, 3.2, 4.0, origin for: America hartz, SMC and nickel, welcome calls for welding procedure and instructions.

Inventory: 254 smo stainless steel plate inventory spot size is 0.5 mm to 18 mm, bar inventory spot size 12 mm - 250 mm Φ Φ, pipe fitting and other can be customized according to customer's requirements. The materials are mainly Japanese metallurgy, Nippon steel and OUTOKUMPU. Provide raw material certificate, customs declaration and certificate of origin.

Application area: oil, petrochemical equipment, such as corrugated pipe of petrochemical equipment, pulp and paper bleaching equipment, such as pulp digester, bleaching equipment, filtering, washing with bucket cylinder and roller, etc., power plant flue gas desulfurization device, main use parts: absorption tower of the tower body, the flue, door plank, internal parts and spray system, sea systems or water treatment, such as power plant using thin wall condensation pipelines, cooling sea water desalination processing equipment may not flow, even in the sea can also be applied in equipment, desalination industry, such as salt or desalination equipment, heat exchanger, especially in the chloride ion heat exchanger in the work environment.