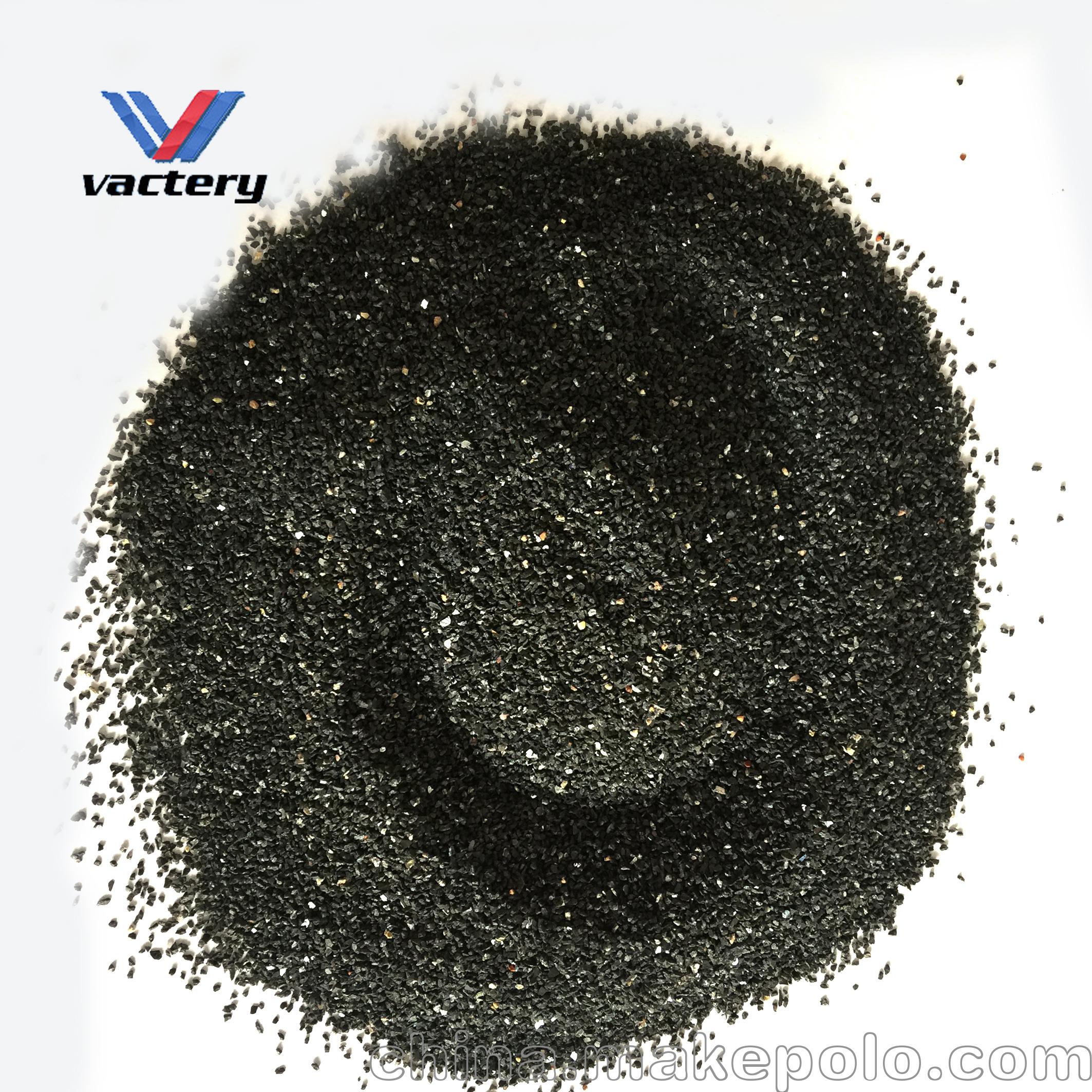

黑刚玉简介

黑刚玉又名低铝刚玉,青刚玉,是于电弧炉中,将铝矾土熔炼而制得的一种AL2O3和铁尖晶石为主矿相的灰黑色结晶体,其特点是AL2O3含量较低,并有一定量的Fe2O3(10%)存在,因而具有硬度适中、韧性大、自锐性、粘结性良好,耐用度高,磨削时发热少,耐高温,不易划伤工件表面,工件表面光洁度高等特点。

Black corundum and low aluminum corundum, blue corundum, is in electric arc furnace, the bauxite made by melting a AL2O3 spinel is given priority to with iron ore phase of the colored crystals, its characteristic is AL2O3 content is lower, and has a certain amount of Fe2O3 (10%), and therefore, moderate hardness and great toughness, self-sharpening, good bonding, high durability, produce less heat when grinding, high temperature resistant, not easy to scratch the surface of the workpiece surface roughness is high.

黑刚玉物理指标

颜色 | 黑色 |

晶形 | 三方晶系 |

硬度(莫氏) | ≥9.0 |

熔点(℃) | 2050 |

最高使用温度(℃) | 1850 |

真密度(g/cm3) | ≥3.50 |

线膨胀系数(0—1600℃) | 7—9 |

黑刚玉化学指标

规格 | 主要化学成分% | |||

Al2O3 | Fe2O3 | SiO2 | TiO2 | |

一级 | 85 | 6-9 | 5-8 | 2-4 |

二级 | <80 | >9 | >8 | >4 |

黑刚玉性能特点

黑刚玉硬度适中,其韧性较大耐磨棱角锋利,自锐性强,磨削是发热量少,抛光加工工件洁度高,其抛光性能大大高于国内外其他同类产品,铝含量大于82%黑刚玉硬度高、韧性大,刚柔相济,耐磨耐用;其粘结性和亲水性好,便于上磨盘;磨削时堵塞少,发热少,工件不会烧伤;自锐性强,工效高,且加工面无划痕,抛光洁度高;比棕刚玉抛光能力提高一倍以上,抛光洁度提高二级以上。

Black corundum hardness is moderate, the toughness is bigger wear-resisting sharp edges and corners, the sharpness is strong, grinding is less calorific value, high pure degree of polishing machining, the polishing performance much higher than other similar products at home and abroad, the aluminum content is greater than 82% black corundum, high hardness and great toughness and flexibility, wear-resisting and durable; It is cohesive and hydrophilic, and it is easy to make the mill. Less congestion, less heat, no burns; Self-sharpness, high efficiency, and no scratches on the surface of the processing surface. More than double the polishing ability of the brown alumina jade, and more than two levels of polishing.

黑刚玉应用

黑刚玉主要应用于自由研磨,如金属零件电镀前底面抛光、铝制品,适用于自行车、摩托车、缝纫机、钟表零部件、灯饰、塑胶及五金工具等的抛光,亦适用于喷砂(除锈、玻璃喷花),加工材料,制造树脂切割片、角磨片和涂附磨具等。黑刚玉粒度砂和微粉特别适合于不锈钢工件的研磨抛光及油石、研磨膏的制造,黑刚玉段砂更是防滑路面和煤矿坑下仓储的可选材料。

1、自由研磨,如金属零件电镀前底面抛光、铝制品。

2、自行车、摩托车、缝纫机、钟表零部件。

3、灯饰、塑胶及五金工具等的抛光,亦适用于喷砂(除锈、玻璃喷花)。

4、加工材料,制造树脂切割片、角磨片和涂附磨具等。

5、黑刚玉粒度砂和微粉特别适合于不锈钢工件的研磨抛光及油石、研磨膏的制造。

6、黑刚玉段砂更是防滑路面和煤矿坑下仓储的可选材料。

Black corundum is mainly used in free grinding, such as floor polishing before plating metal parts, aluminum products, suitable for bicycle, motorcycle, sewing machine, clock parts, lamp act the role ofing, plastic and hardware tools, such as polishing, is also suitable for sandblasting (spray derusting, glass flower), materials processing, manufacturing resin cutting, Angle grinding pills and coated abrasive, etc. Black corundum sand granularity and micro powder particularly suitable for grinding and polishing of stainless steel workpieces and sharpening stone, grinding paste, black corundum sand antiskid pavement and coal mine under the optional material warehouse.

1, lapping, such as metal parts polishing, aluminum products.

Bicycles, motorcycles, sewing machines, watch and watch parts.

Polishing of lighting, plastic and metal tools, also apply to sandblasting (rust and glass spray).

Processing materials, manufacturing resin cutting pieces, Angle grinding pieces and rubbing tools, etc.

It is suitable for grinding and polishing of stainless steel workpieces and the manufacture of oil stone and polishing paste.

The black corundum sand is an optional material for both slippery surface and coal pit.