-101 tower crane safety monitor user manual

Head office

Guangzhou Asshop Technology Co.,Ltd.

First, the system functions

-101series of tower crane safety monitoring system include tower crane collision warning, emergency stop, regional protection of the tower crane, tower crane’s construction environment monitoring and tower crane movement status monitoring, with real-time alarm , stop, black box function.

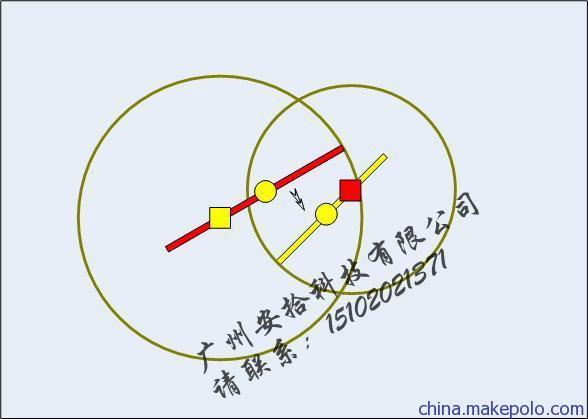

1. Tower crane collision warning(1)) collision warning between the tower arms

When the towers are working at the same altitude, their arms might collide with each other(including the jibs and counter jibs), the tower crane safety monitoring system will send alarm signal when their arms are getting too close. It can remind the drivers’ caution, and automatic shut off if the drives did not stop manually.

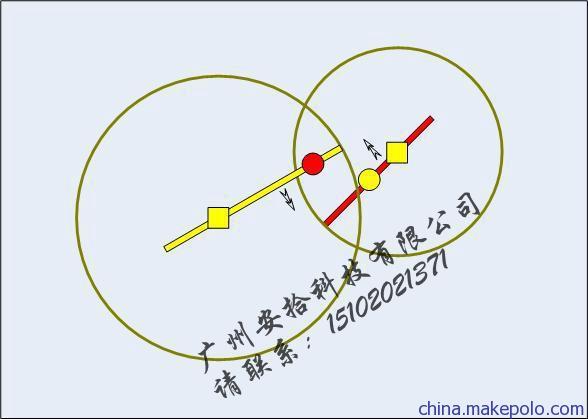

When the two tower cranes are not working at the same altitude, the lower tower crane’s arm might collide with the higher tower’s mast.

The tower crane safety monitoring system will send alarm signal when lower tower crane tower’s arm getting too close to the higher tower’s mast. It can remind the drivers’ caution, and automatic shut off if the drives did not stop manually.

(3)the tower arm and the rope collision warning

When the two tower cranes are not working at the same altitude, the lower tower crane’s arm might collide with the higher tower’s hook and rope.

The tower crane safety monitoring system will send alarm signal when lower tower crane tower’s arm getting too close to the higher tower’s hook and rope. It can remind the drivers’ caution, and automatic shut off if the drives did not stop manually.

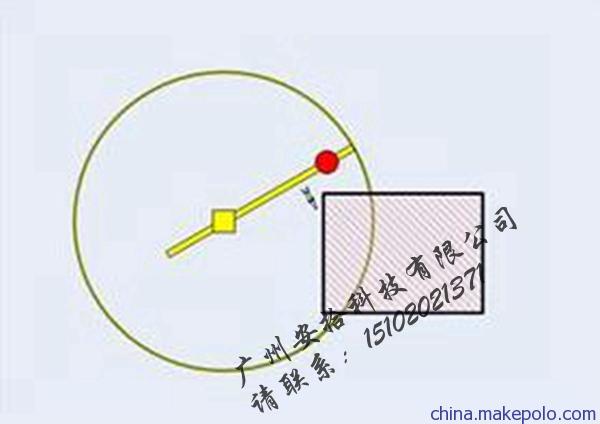

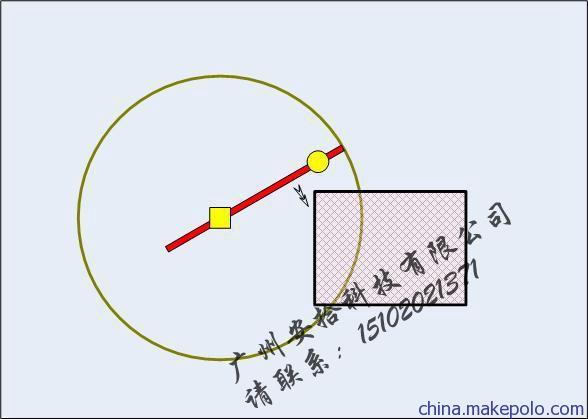

(1) crane arm region protection

Limiting the crane’s arm to enter certain areas, to prevent the collision between the crane arm and the buildings, telephone poles and other stationary obstacle. As shown below.

Limiting the hook move into certain areas, to prevent the rope, hook and the lifting objects to collide with the buildings, telephone poles and other stationary obstacle.

Monitor the tower crane’s loading capability. Based on the wind speed and the tilt of the tower crane at working site, to prevent the collapse of the tower crane, or hanging heavy objects falling.

Compared with similar products,AS-101 series of tower crane safety monitoring system has the following characteristics:

u The advanced algorithm to ensure sending the alarm signal on time.

u additional installation, does not change the original line and the structure of the tower crane, will not produce any negative effects

u sound and light warning, simple and convenient to get drivers’ attention to the danger, and will not distract drivers’ attention

u Intelligent braking, when sound and light warning invalid, automatic power shut off to avoid the occurrence of high-risk situations

u full-featured set of rotation, range, weight, height, wind speed, several upgrade option.

u centralized management of all data changes and parameter adjustment can be completed in the control room without the need for onsite operations

u focus on observation, the control room have in real-time observation of the tower crane’s operation, the ability to detect the fault

u reliable communication module, long transmitting distance, the strong ability to cross through barriers.

u easy installation and removal, the installation process is not affecting the tower crane operations

u easy to use, the driver does not need to modify any data, to avoid human caused error

u small size, compact structure, occupied a small cabin space, easy to install and use

Table 1 -101 tower crane safety monitor key performance indicators

No | type | project Name | Index |

1 | rotation angle sensor ° | Measuring range | 0-360° |

Resolution | less than 0.18 | ||

2 | range sensor | Measuring range | 0-80m |

Resolution | less than 0.05m | ||

3 | height sensor | Range | 0m from 300m |

Resolution | Less than 0.05m | ||

4 | Weight sensor | way | 2-20t |

Resolution | Less than 50kg | ||

5 | Wind speed sensor | Range | 0-40m/s |

Resolution | 0.1m/s | ||

6 | tilt sensor | Range | 0-15° |

Resolution | 0.01° |

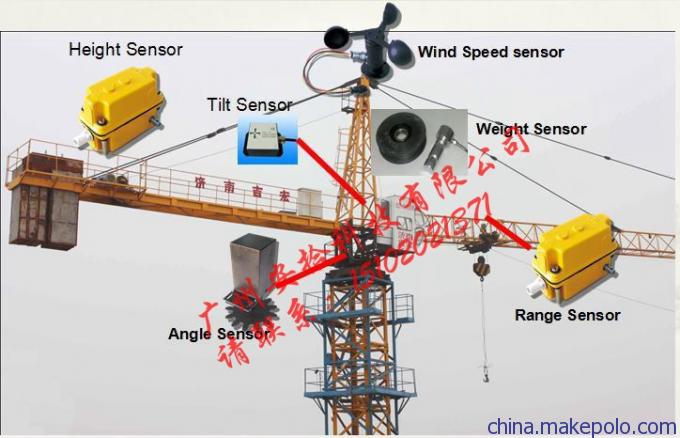

Third, the system components

AS-101tower crane safety monitoring system composed by sensors and the host.

Table 2 -101tower crane safety monitor system components

No | Description | Qty |

1 | Anti-collision system main board (internal or external liquid crystal display) | 1 |

2 | angle sensor | 1 |

3 | range sensor | 1 |

4 | height sensors (optional) | 1 |

5 | tilt sensor (optional) | 1 |

6 | wind speed sensor (optional) | 1 |

7 | weight sensor (optional) | 1 |

8 | antenna cable | 1 |

9 | sucker antenna | 1 |

10 | power line | 1 |

l Power Requirements: AC 220V ± 10%

l Operating temperature: -20 to 60 ° C

l Operating Humidity: 0 ~ 95%

The angle sensor install in the tower crane’s slew meshing gear, range sensor install in the trolley’s amplitude limiter linkage axis; height sensor install in the trolley’s height limiter linkage axis; tilt sensor install in the cross beam of the crane arm; wind speed sensor install on the top of the tower crane; weight sensor install in the force of the tower crane fixed pulley. Sensors by connecting the cable access to the anti-collision alarm main board, through the mounting bracket secured to the body of the tower crane machine, sucker antenna and tower crane safety monitoring main board install in the tower crane cab.

Power cord, signal cable interface are the three core and four core.

In order to ensure reliable operation, installation environment requirements are as follows:

1. Supply voltage should meet the equipment requirements, and properly grounded;

2. Device securely mounted to prevent any part of loss and mechanical damage;

3. Cable should be properly layout, away from the mechanical operation of the institutions, and prevent injury composition

4. The main board should be away from heat, keep the air vents unobstructed

5. The main board is placed in a dry environment.

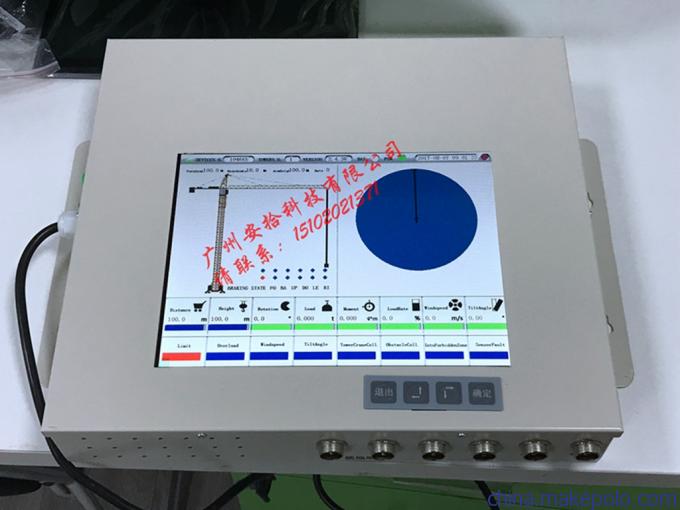

1 Screen

(1) tower crane has a round face

² tower crane with blue color is normal;

² tower crane’s circle with green color is normal, yellow is an early warning, red a serious warning

(2) the tower crane arm shaft

² tower crane arm

(3) obstacles

² purple

(4) the tower crane

² tower crane network number.

(5) host(main board) No.

² tower crane safety monitoring number.

(6) rotation (degrees)

² this tower crane’s arm angle in degrees.

(7) range (m)

² The tower crane trolley’s current location, in meters.

(8) Height (m)

The tower crane hook’s current location, in meters.

(9) Weight (kg)

² the tower crane lifting ojectss in units of kilograms.

(10) tower arm loading capability (kN m)

² the tower crane’s loading capability , in units of kN/ m.

(11) wind speed (m / s)

² current wind speed of working site in m / s.

(12) Inclination/tilt (degrees)

² The tower crane’s inclination, in degrees.

(13) warning status

² Normal:fine;

² Serious warning: warn1;

² Early warning: warn2.

The early warning: warn2.

(14) warning reason

² Non warning:no

² The collision warning: warn11, warn12;

² The tilt warning: warn12, warn22;

² wind speed warning: warn13, warn23;

² Overweight warning: warn14, warn24;

² torque warning: warn15, warn25.

2 buzzer

² it used for alarm and tips. Early warning and serious warning 3 Power switch

² host power 4 VGA connector

² external display 5 Power Interface

² connect with 220v power. connect properly plase.

6 sensor interface

² connect corresponding specific sensors, including range, height, weight, angle, wind speed, and tile sensors. Please ensure a reliable connection.

²

7 brake interface

² corresponding connecting to the tower crane’s all direction switches(up, down ,front,

back ,right and left) 8 fan exhaust hole

² smooth fan exhaust, do not block to ensure normal cooling 9 change the frequency

² change the radio frequency of the host 10 Antenna Interface

² Connect the sucker antenna, should ensure that the antenna is properly connected before turn the host on, otherwise it may cause a host failure.

11 tower crane collision warning light

² The red and flashing, indicating that the tower crane in the region have a risk of collision 12 collision control switch

² collision control switch 13 collision control indicator

² collision control indicator

1. 1 year warranty and lifetime maintenance.

2. The starting date of the warranty period is according to the product invoice date.

3. The following circumstances are not covered by the warranty: Damage caused by improperly use, maintenance and custody.

damage caused by disassemble or repair od Non-designated officer. Non-formal channels purchase, without a valid invoice.

Damage caused by force majeure.

4. Not covered by the warranty products, the Company's service sector is still welcome for your questions.

Ø As for drivers:

1) Tower crane driver should turn on the tower crane safety monitoring system before lifting.

2) Exercise caution when alarm is activated.

3) When the tower crane is not operating, the tower crane should be placed in open areas and turn off the system.

4) After the alarm is issued, the tower crane driver should carefully observed the tower crane’s location, visual range, if necessary, can consult the control center and confirm the safe distance.

5) please do not be open or unplug any part of the anti-collision system after the installation.

6) Take good care of the equipment, is strictly forbidden to beat and stampede the equipment.

7) if discover any Abnormal activities and questions please contact the Safety Officer.

Ø As for managers:

1) During the operation of the tower crane safety monitoring system, ensure that the remote controller's power supply and ensure their normal operation.

2) During the operation of the tower crane safety monitoring system, tower crane controller should the turn on to ensure it operate normally and recording the tower crane’s working status.

3) Strengthen the management and training of tower crane drivers, listen to the tower crane drivers’ suggestion , according to the real situation to modify the safe distance, alarm volume level.

4) After the tower crane is normally erected, modify the height parameter of the tower crane timely.

5) After the tower crane have a wire rope replacement, if necessary to reset the relevant parameters of the sensors, please contact the manufacturer.

6) Consult the tower crane drivers regularly, watch the tower crane’s operating records, please contact the manufacturer if any abnormal activities were found.

7) It is strictly prohibited to open or tear apart of the tower crane safety monitoring system and its components, there is any questions please contact the manufacturer.

Special Note

1. This product is an auxiliary device use to alarm and control any dangerous operation of the tower crane , all tower crane operations must be completed by the operator.

2. System’s mechanical and electrical components may fail, Do not passively rely on this system.

Do not make any risky operation because of this product.

3. product’s technical improvements will be incorporated into the new version of the specification without prior notice; in event of product’s appearance changed, the last version shall be taken as valid.