调味料、氨基酸、石墨、瓷粉烘干机天泽牌喷雾干燥机

常州市天泽干燥设备有限公司

中国 常州

产品属性

图文详情

品牌推荐

品牌

天泽

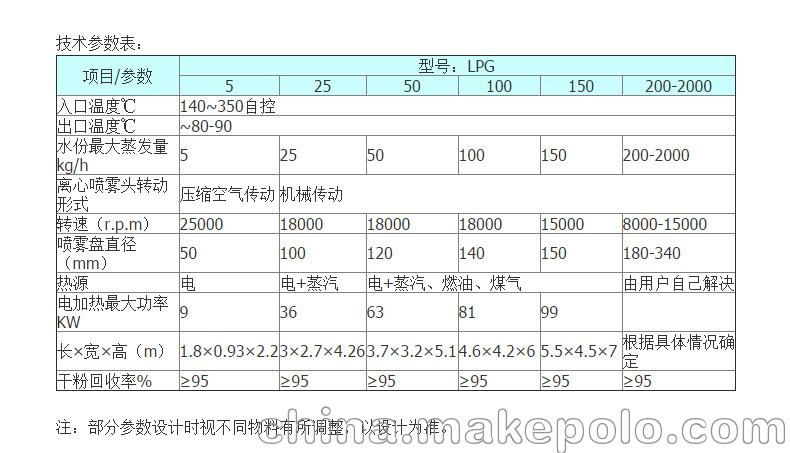

型号

LPG-5

雾化方式

离心式

操作方式

连续

物料输送方式

喷雾化输送

适用物料

悬浮液及溶液

干燥介质

空气

加工定制

加工定制

入口温度

140-300可控℃

出口温度

80-90℃

水份最大蒸发量

5kg/h

电加热最大功率

9kW

喷雾盘直径

50mm

离心雾化器转速

25000r/min

干燥塔直径

0.9

热源

电

外形尺寸

1.8x0.93x2.2mm

重量

800kg

调味料、氨基酸、石墨烘干机天泽牌喷雾干燥机

| Specifications |

| Centrifugal spray dryer: |

| 1,The powder was made from solution directly. |

| 2,fast in drying, uniform in size, good in fluidity. |

| 规范 |

| 离心喷雾干燥机: |

| 1、溶液可直接制成粉末状。 |

| 2、干燥速度快,粒度均匀,流动性好。 |

| Description of centrifugal spray dryer: |

| The spray drying is the widest used technology in the liquid shaping technology and in the drying industry. It is most suitable for producing powder, particle, or block solid products from materials of solution, emulsion, soliquoid and pumpable paste states. Therefore, when the particle size and distribution of the final products, their residual water contents, the stocking density and the particle shape meet the precision standards, the spray drying is one of the most desired technologies. |

| 离心喷雾干燥机描述: |

| 喷雾干燥是液体成型技术和干燥工业中应用最广泛的技术。适用于从溶液、乳液、固形物和可泵送的糊状物料中生产粉状、颗粒状或块状固体产品。因此,当最终产品的粒度和分布、残余含水量、密度和颗粒形状均达到精度标准时,喷雾干燥是最理想的工艺之一。 |

| Features of centrifugal spray dryer: |

| 1, High speed of drying. After the spraying of he material liquid, the surface area of the material will be increased greatly. In the hot-air flow, 95%-98% of water can be evaporated at a moment. The time of completing the drying needs only several seconds. |

| 2, It is especially suitable for drying the heat sensitive materials. It’s final products own the good uniformity, mobility, dissolving capacity. And the final products are high in purity and good in quality. |

| 3, The production procedure is simple and the operational control is easy. The liquid with the moisture contents 40-60%(for special materials, the contents may reach 90%) can be dried into power or particle products once a time. After the drying, there is no need for smashing of sorting, so as to reduce the operation procedures in the production and enchance the purity. The product particle diamenters, looseness and water contents can be adjusted through changing the operation condition in a certain scope. It is very convenient to carry out the control and management. |

| 离心喷雾干燥机的特点: |

| 1、干燥速度快。喷涂原材料液后,材料的表面积将大大增加。在热风流动中,95%-98%的水可以瞬间蒸发。干燥完成只需几秒钟。 |

| 2、特别适用于热敏性物料的干燥。产品具有良好的均匀性、流动性、溶解能力。产品纯度高,质量好。 |

3、生产工艺简单,操作控制简单。水分含量40-60%的液体(特殊物料可达90%)可一次干燥成粉状或颗粒状产品。干燥后无需粉碎分选,减少了生产中的操作程序,提高了产品的纯度。通过在一定范围内改变操作条件,可以调节产品的粒度、疏松度和含水量。

|

| 适用范围: |

| 化工:有机催化剂、树脂、合成洗衣服、油脂类、染料、染料中间体、石墨等。 |

| 食品:氨基酸及类似物、调味料、蛋白质、淀粉、乳制品、咖啡提取物、鱼粉、肉精等 |

| 制药:中成药、农药、抗生素、医药冲剂等。 |

| 陶瓷:氧化镁、瓷土、各种金属氧化物、滑石粉、白云石等。 |

| 注:易燃易爆物品禁用。 |

| 订货须知: |

| 1、物料名称、属性:含固量或含水量,粘度、表面张力、PH值。 |

| 2、干燥后粉料容量、允许残余含水量、粒度、允许*温度, |

| 3、产量:每天工作时长。 |

| 4、可供能源:蒸汽压力可供量、电容量、可供燃煤、油、气量。 |

| 5、控制要求:进、出口温度是否需要自控。 |

| 6、授粉要求:是否安装袋式捕集器,环境对排放尾气要求。 |