循环腐蚀试验箱的功能及案例介绍

检测能力(Test abiliy) :

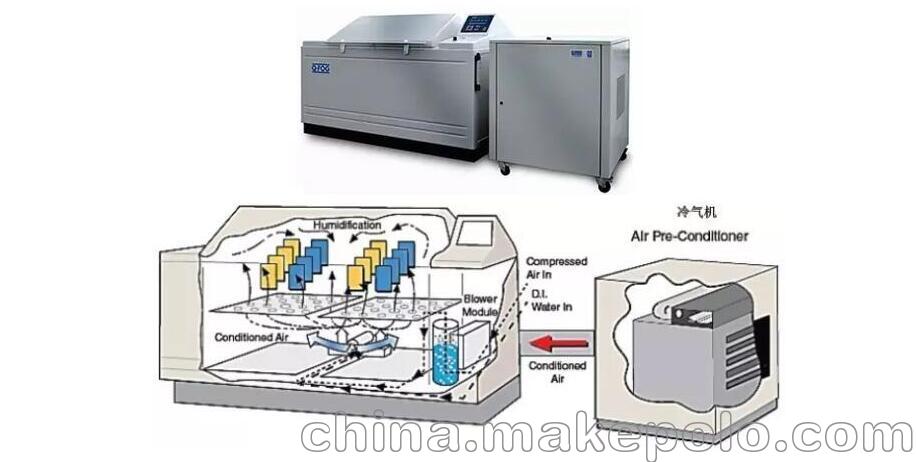

循环腐蚀试验(CCT): 该项试验包含盐雾、温度变化、 干湿交替等工况,模拟汽车零部件在户外经历的大部分腐蚀环境,与户外的相关性较好。

Cyclic Corrosion Test (CCT): The test includes salt fog, temperature change test anddry/wet alternately, simulating most corrosive environments of auto parts gothroughoutdoor, has good rank order correlation with outdoor corrosion.

设备参数(Parameters):

案例应用Case application

理论上,循环腐蚀试验适用于所有汽车金属零部件。截止目前,已验证和制定了针对电泳、喷涂类涂层产品、不锈钢产品、铸铝件产品的一系列循环腐蚀试验方法。其中,铁基材的电泳、喷涂类涂层产品、不锈钢产品的循环腐蚀试验方法可参考Q/BYDQ-A1901 .886- 2014 《汽车零部件耐腐蚀试验指导规范》,铝制电泳、喷涂类涂层产品、铸铝件产品的循环腐蚀试验方法可参考Q/BYDQ-A1901.959- -2015 《汽车铝制零部件耐腐蚀试验及评价规范》。

Bytheory, cydlic corrosion test applys to all the metal parts of car. By now, wehave worked out a series of cyclic corrosion test methods forcoating or plating parts, stainless steelparts and aluminium castparts. Standard Q/BYDQ-A1901.886 -2014 is aplying to coating or plating parts made ofsteel and sainless steel parts. Standard Q/BYDQ-A1901.959-2015 isapplying to coating or plating parts made of aluminium& aluminium lly, and aluminium cast parts.

典型案例:车身涂层试板的腐蚀试验表明,循环腐浊试验相比于中性盐雾试验,与驴外的腐蚀相关性更好。

Typicle case: Cyciccorrosion test is moresuitable for car body coating panel compared to NSS test,it has good order corelation with outdoor corrosion.

东莞市瑞凯环境检测仪器有限公司高低温湿热试验箱(恒温恒湿试验箱)、步入式恒温恒湿试验室、高低温/冷热冲击试验箱20余年的奋斗与发展,瑞凯已成为国内环境可靠性试验设备、实验室仪器行业的旗舰与知名生产厂家。公司于2013年通过了国家高新技术企业认定,在中国,瑞凯的环境试验设备已经落户国内各地,哪里有质量可靠的产品,哪里就有瑞凯的设备。

Rui Kai environmental testing instrument Co., Ltd., high and low temperature hot and humid test chamber (constant temperature and humidity test box), progressive constant temperature and humidity laboratory, high and low temperature / cold and hot impact test box for more than 20 years of struggle and development, Rui Kai has become the domestic environmental reliability test equipment, laboratory equipment industry flagship and well-known manufacturers. In 2013, the company passed the national high-tech enterprise. In China, Rui Kai's environmental test equipment has been located in all parts of the country, where there are reliable products, where Rui Kai's equipment.