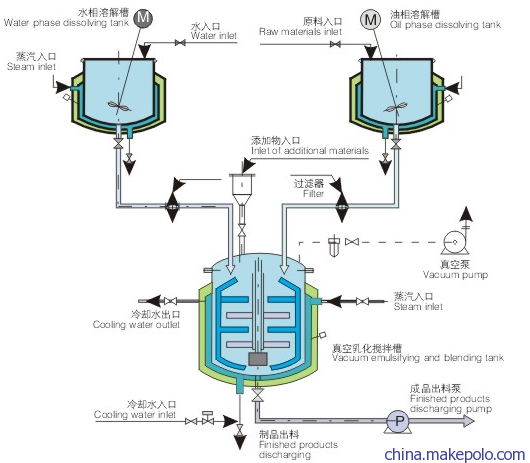

ZRJ-300L真空乳化搅拌机

ZRJ-500L真空乳化机 1. 结构形式:有主机1台,油相锅1只,水相锅1只,操作平台1件等组成。主锅,油相锅,水相锅的内胆材质316L,夹套材质304,外套材质304。 2. 主锅有效容量550L,工作量500L,油相锅有效容积250L,水相锅有效容量310。油水锅主要将物料预热,然后进入主锅乳化。 3. 加热方式:电加热,功率主锅12kw,油相锅8kw,水相锅8kw。夹套内可进行油加热或进水加热,如果进油加热必须配一只油罐容积为150L,配一台转油泵,就可以循环加热。 4. 冷却方式:自来水冷却。 5. 乳化方式:均质器与高速切剪刀进行乳化。电机功率7.5kw-2p变频调速。 6. 搅拌方式:框式回流搅拌桨进行搅拌及刮壁,功率3.7kw-4p变频调速。 7. 开盖方式:双杆液压升降,电机功率2.2kw,配有安全自锁装置。 8. 进料方式:真空自吸进料,主要由油相锅和水相锅的物料进入主锅乳化。 9. 出料方式:有三种,1.底部气动出料 2. 电动倒锅出料 10. 控制方式:所有动作及温度均由触摸屏控制(包括进出料) 11. 外开尺寸:主机长×宽×高,2900×1200×2600mm。工作时上升高度3800mm 包含油水锅整套外形尺寸:长×宽×高 3500×3050×2600mm

3. 正气压出料。

1.Dimention: 2400L×1600W×1670H×2300mm(Fully height)。

2.

Emulsification Boiler:50L with SUS316L,Heated by electricity and cooled by

water

3.

Emulsification Boiler Structure: Two jacket structure .the inner deck is SUS316L,5mm

thickness and polished in 300MESH.Middle deck is SUS304,4mmThickness and

working pressure 0.3Mpa. The outer deck is SUS304,2mmand polished in 300MESH.Heat preservation jacket

adopt Polyurethane Foam technics.Stir power is 0.75KW with 1420r/min.Material

outlet is with pneumatic discharging valve.the cover is connected with the

boiler body by clamp.

4

.Emulsification boiler with 3 sets stirring device:

a.Homogenizer: 3KW ,0-3600r/min(speed by

transducer)

b. impeller: 0.75KW ,0-100r/min(speed by transducerk)

c.

Scraper is conversely running,sharing the same motor with impeller with

0-100r/min

5

Main Parts on the Emulsification Boiler:

the material inlet with the filter,,adding

material inlet,Vacuum,vent,Sight glass,Temperature sensor,CIP,material outlet,safty

valve,pressure meter,negative

pressure sensor ects devices.。

6.

Pre-treatment Boiler:(A material Boiler,B material Boiler)

A

and B Boiler:45L

,heated by electricity ,cooled by water

Design:the

boiler’s cover can be half open.Boilers are with stir and temperature

controller.

Two

jacket structure :the inner deck is SUS316L,5mm

thickness and polished in 300MESH.Middle deck is SUS304,4mm

Thickness and working pressure 0.3Mpa. The outer deck is SUS304,2mmand polished in 300MESH.Heat

preservation jacket adopt Polyurethane Foam technics.Stir power is 0.75KW with

1420r/min.Material outlet is with pneumatic discharging valve.the cover is connected

with the boiler body by clamp.

7.Hydraulic

pressure system:

oil

tank,oil vat,Solenoid valve,Overflow valve,Hydraulic circumfluence

control Valve etc.。

8 .Vacuum System:

Vacuum

Pump of the Emulsification Boiler : Model ZBV2060

Evacuating

Air :32㎡/h

Power:0.75KW

9.Electrical Controlling

System:

Touch Screen:Siemens

Transducer:Panasonic

Button:Schneider

Meter,Sensor,Temperature Controller:Chinese

famouse brand

*The

Emulsification,Heating,and cooling time can be input in the Touch Screen ,and

the control is automatical

10.Seal

Seal

Material:Silicon O-ring

11. wire head is clamped and with the cap.

12. this machine is pided into two parts,The Emulisification Boiler and A

and B Boiler.The A and B boiler can be designed

with the moving wheel which is the brake function or can be designed

with the working stage .

13 .Each corners on the surface are in arc and smooth.