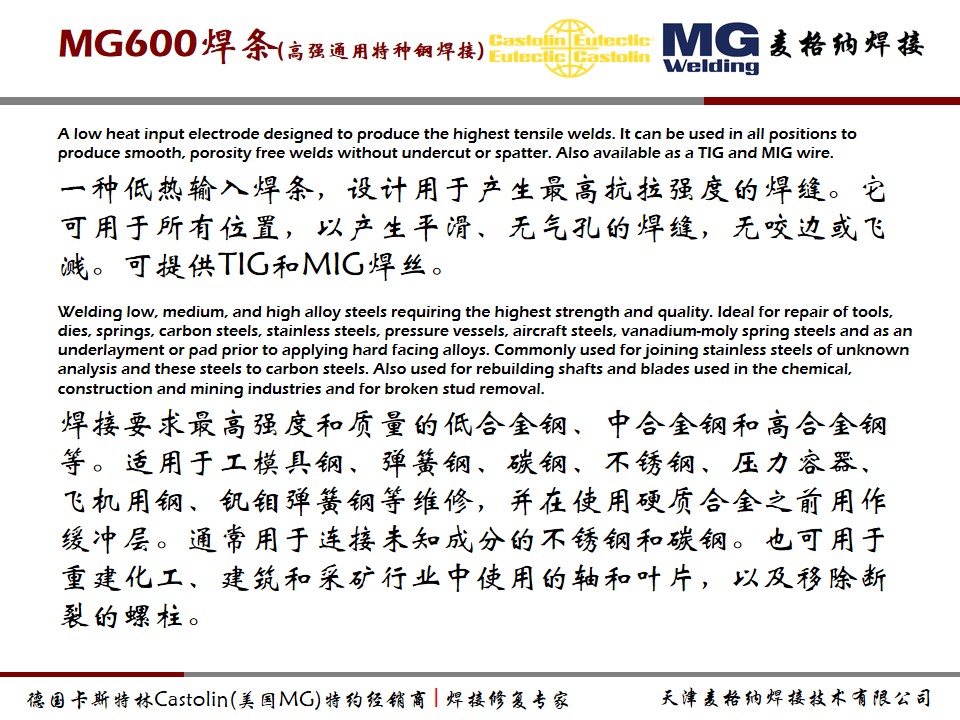

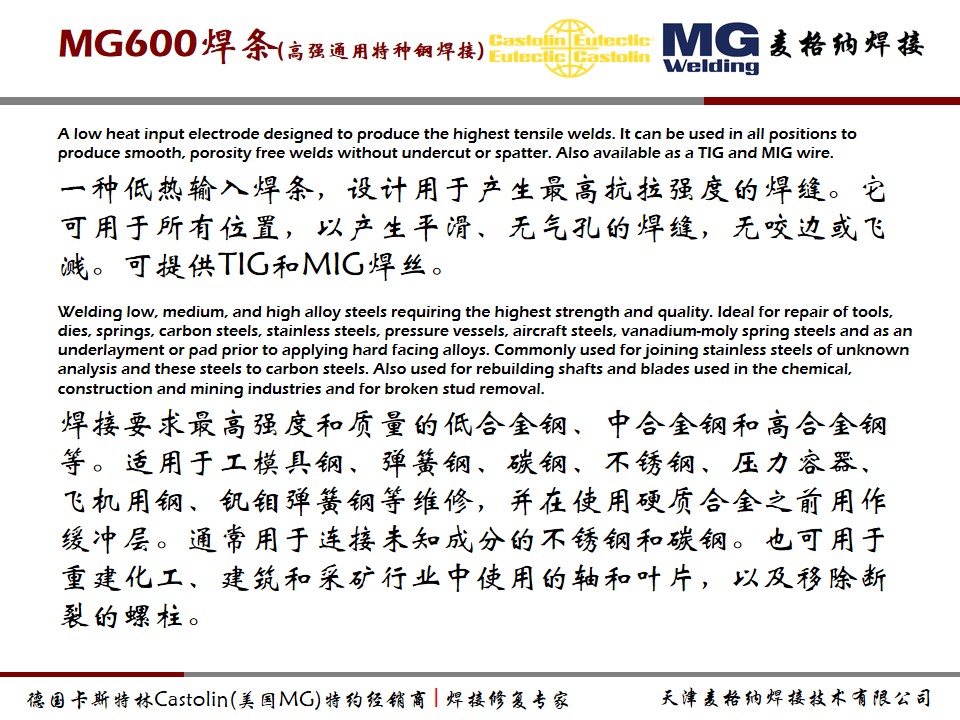

德国卡斯特林Castolin美国MG600特种钢焊条|A5.4 E312-17|难焊钢|未知钢|异种钢焊接

Typical All Weld Metal Mechanical Properties(As Welded)

典型全焊缝金属机械性能(焊态):

Ultimate Tensile Strength抗拉强度:827 N/mm2

Yield Strength 屈服强度: 621 N/mm2

Elongation延伸率: 28%

Hardness硬度: 300 HB

Sizes Available and Recommended Amperages

尺寸Φ/电流:

1.6mm | 2.4mm | 3.2mm | 4.0mm | 5.0mm |

30-40A | 40-80A | 65-120A | 90-150A | 140-220A |

Current电流:AC/DC (+)

Related Specification参考标准:AWS A5.4 E312-17

PROCEDURE:

焊接工艺:

Prepare joint area by removing foreign material. Bevel heavy sections to form a 90° vee. Hardenable alloys should be preheated. Use jigs, fixtures and tack welds to maintain alignment. Hold a short arc. Stringer beads are preferred to prevent overheating. Allow to cool before removing slag. Deposits will take a high polish when subjected to wear.

通过清除异物来准备接合区域。斜切厚截面部分,形成90°V形。可硬化合金应预热。使用钻模、夹具和定位焊缝保持对齐。保持短弧。为了防止过热,推荐使用线状焊道。在清除熔渣之前,让其冷却。沉淀物在磨损时需要高度抛光。