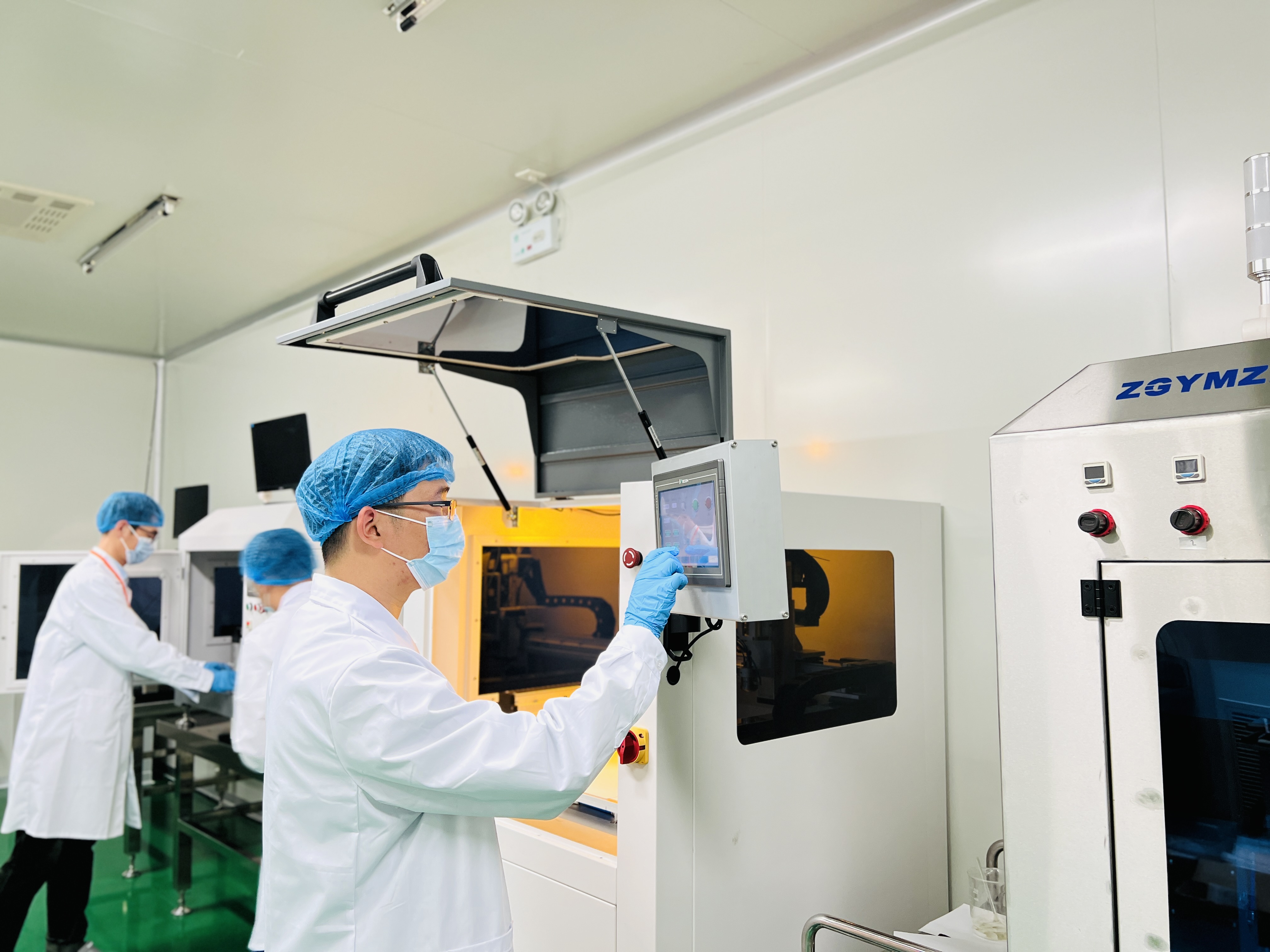

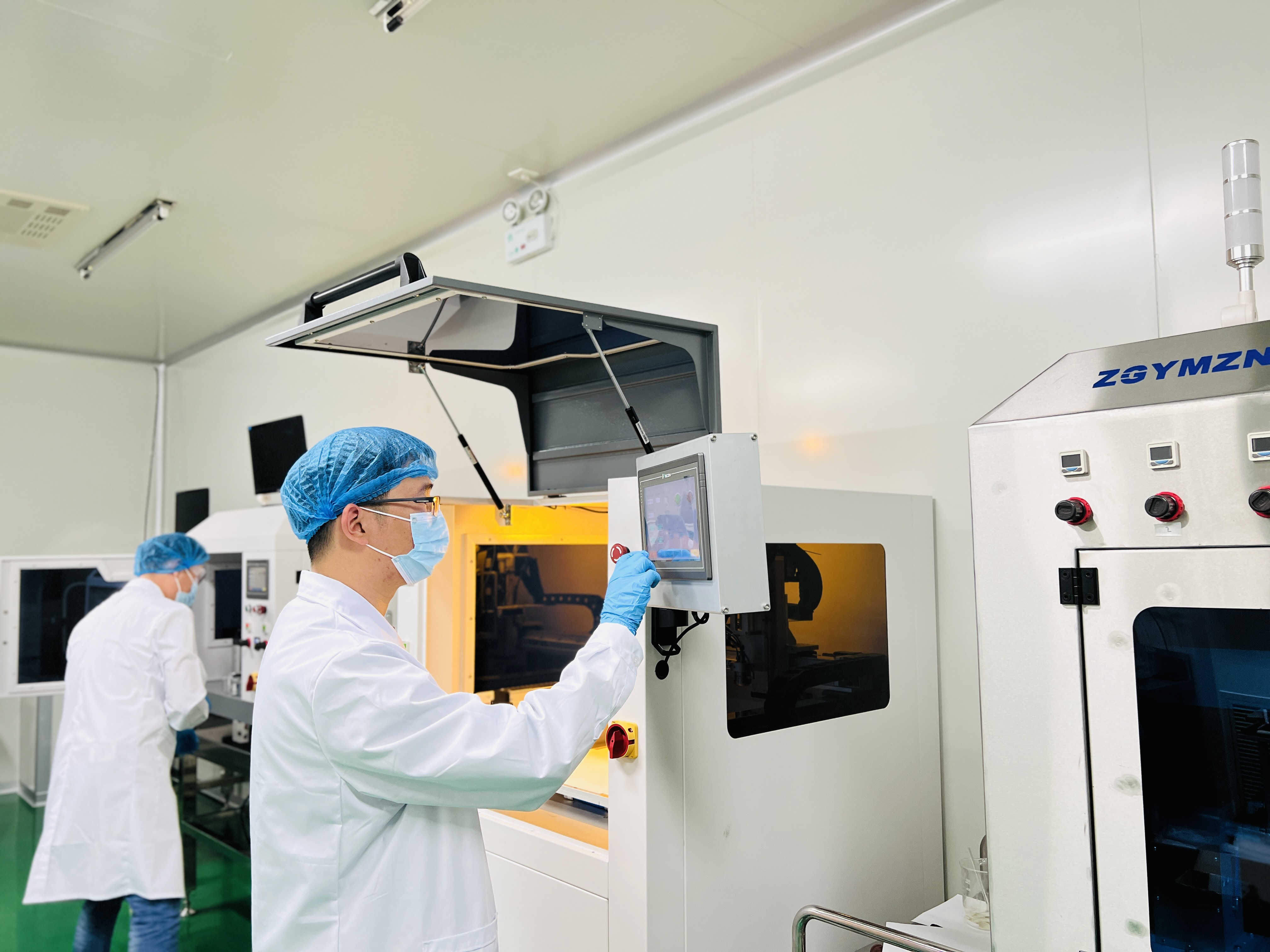

超声波精密喷涂-光伏电池喷涂

超声波精密喷涂-光伏电池喷涂

中国已成为全球主要的太阳能电池生产国。2006年全国太阳能电池的产量为438MW,2007年全国太阳能电池产量为1188MW。中国已经成超越欧洲、日本为世界太阳能电池生产大国。2008年的产量继续提高,达到了200万千瓦。

太阳能光伏电池(简称PV电池)是用来将来自太阳的光能直接转化为电能的。地面光伏系统中使用了大量的硅基硅太阳能电池,可分为单晶硅、多晶硅和非晶硅太阳能电池。在能量转换效率和使用寿命方面,单晶硅和多晶硅电池优于非晶硅电池。

超声波喷涂是一种独特的雾化技术,它是以超声波雾化喷嘴技术为基础的。所喷涂的物料先为液体状态,液体可为溶液、溶胶、悬浮液等,涂覆的液体经超声雾化装置雾化成细小颗粒,再由一定量的载流气体均匀涂覆在基材表面,从而形成涂覆或涂膜。与传统的气动双流体喷涂相比,超声雾化喷涂均匀性更好,涂层厚度更薄,精度更高。同时,由于超声波喷喷嘴不需要空气压力来雾化,所以使用超声波喷涂可以大大减少原料喷溅的喷涂过程,达到节约原料的目的,使用超声波喷涂的涂料是传统二流体喷涂的4倍以上。

超声波喷头是利用压电换能器将高频声波转化为机械能,进行纵向高频振动。液体波从超声喷嘴向上延伸,直到被分离成大小均匀的液滴。二次成型气体或周围的空气可以很容易地将液滴包裹到所需的形状和速度,从而实现各种各样的喷涂。

应用于光伏电池涂层:

超声喷涂技术可在薄膜和钙钛矿太阳能电池制造中成功沉积抗反射层、TCO涂层、缓冲层涂层、PEDOT和活性层。OPV, CIG, CdTE, CzT,钙钛矿和DSC是一些溶液和悬浮液,可以沉积在利用超声波湿喷涂技术制备薄膜太阳能电池。超声波喷涂系统降低了制造薄膜太阳能电池的成本,同时仍然提供了高的电池效率。

用于光伏电池涂层的优点:

1、 喷涂图案容易形成,适用于太阳能电池的涂层应用。

2.、任何形状的喷涂都可以形成均匀的微米级涂层。

3、 超声波喷头不堵塞

4、激光定位,快速对准喷涂位置

5、溶液转换率≥95%

Precision ultrasonic spraying-photovoltaic cell spraying

Precision ultrasonic spraying-photovoltaic cell spraying

China has become the world's leading producer of solar cells. In 2006, the national solar cell output was 438MW, and in 2007, the national solar cell output was 1188MW. China has become the world's largest producer of solar cells, surpassing Europe and Japan. In 2008, the output continued to increase, reaching 2 million kilowatts.

Photovoltaic cells (PV cells for short) are used to directly convert light energy from the sun into electric energy. A large number of silicon-based solar cells are used in the ground photovoltaic system, which can be pided into monocrystalline silicon, polycrystalline silicon and amorphous silicon solar cells. In terms of energy conversion efficiency and service life, monocrystalline silicon and polycrystalline silicon batteries are superior to amorphous silicon batteries.

Ultrasonic spraying is a unique atomization technology, which is based on ultrasonic atomization nozzle technology. The sprayed material is in a liquid state at first, and the liquid can be solution, sol, suspension, etc. The coated liquid is atomized into fine particles by an ultrasonic atomizer, and then a certain amount of carrier gas is uniformly coated on the surface of the substrate, thus forming a coating or film. Compared with the traditional pneumatic two-fluid spraying, ultrasonic atomization spraying has better uniformity, thinner coating thickness and higher precision. At the same time, because the ultrasonic spray nozzle does not need air pressure to atomize, the spraying process of raw material splashing can be greatly reduced by using ultrasonic spray, and the purpose of saving raw material can be achieved. The coating using ultrasonic spray is more than four times that of traditional two-fluid spray.

Ultrasonic nozzle uses piezoelectric transducer to convert high-frequency sound waves into mechanical energy, and carries out longitudinal high-frequency vibration. The wave extends upward from the tip of the ultrasonic nozzle until it is separated into droplets with uniform size. The secondary molding gas or the surrounding air can easily wrap the droplets to the required shape and speed, thus realizing various spraying.

Applied to photovoltaic cells coating:

Ultrasonic spraying technology can successfully deposit anti-reflection coating, TCO coating, buffer coating, PEDOT and active layer in thin film and perovskite solar cells. OPV, CIG, CdTE, CzT, perovskite and DSC are some solutions and suspensions, which can be deposited in thin film solar cells prepared by ultrasonic wet spraying technology. Ultrasonic spraying system reduces the cost of manufacturing thin-film solar cells, while still providing high cell efficiency.

Advantages of coating for photovoltaic cells:

1, the spray pattern is easy to form, and is suitable for coating application of solar cells.

2. Even micron coating can be formed by spraying in any shape.

3. Ultrasonic nozzle is not blocked.

4. Laser positioning, quickly aligning the spraying position.

5, solution conversion rate ≥95%