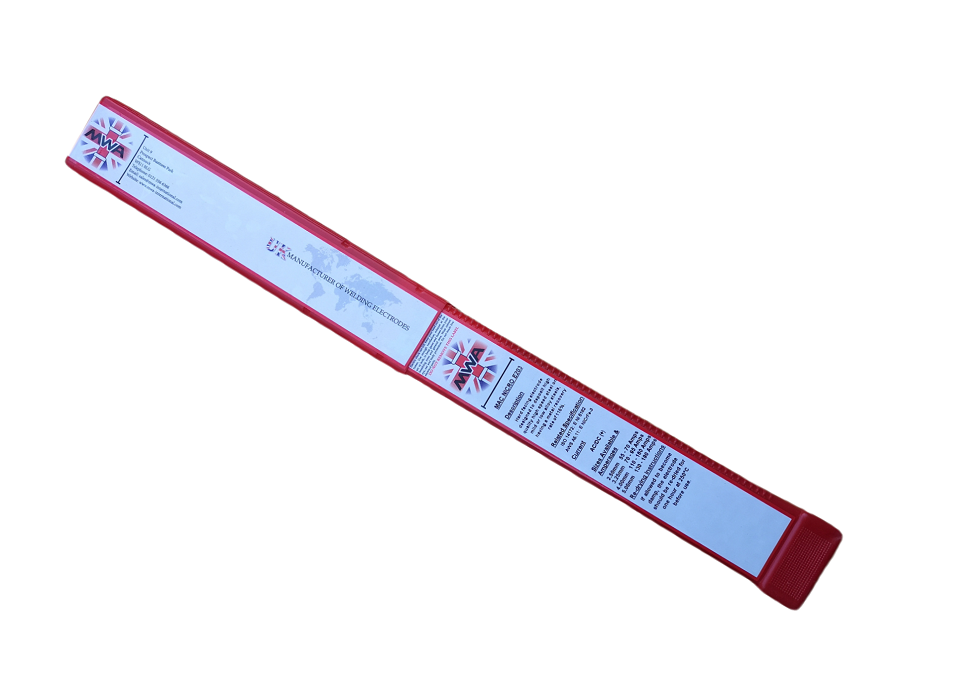

英国进口MWA镍基焊条Mac Nicro E227|E320LR-16|铸锻造合金焊接

Mac Nicro E227 is designed to weld both cast and wrought alloys such as carpenter 20Cb-3 and similar materials with increased nickel levels, this higher nickel level improves resistance to stress corrosion cracking in chloride environments and reduces corrosion rates in the presence of sulphuric acids. Mac Nicro E227 may also be used to weld leaner nickel alloys of the 20.29.3 Cu Nb classification. The risk of weld metal microfissuring is eliminated by a relatively low silicon level and a high manganese to silicon ratio plus low sulphur and phosphorus levels.

E227镍基焊条设计用于焊接铸造和锻造合金,如Carpenter 20Cb-3和镍含量更高的类似材料,这种较高的镍含量提高了氯化物环境中的抗应力腐蚀开裂能力,并降低了硫酸环境下的腐蚀速率。E227也可用于焊接20.29.3 Cu-Nb等级的贫镍合金。相对较低的硅含量、较高的锰硅比以及较低的硫和磷含量可消除焊缝金属微裂纹的风险。

Typical All Weld Metal Chemical Analysis (%)

典型全焊缝金属成分 (%)

C | Cr | Cu | Mn | Mo | Nb | Ni | P | S | Si |

0.05 | 20 | 3.5 | 2.1 | 2.5 | 0.65 | 35 | 0.012 | 0.005 | 0.25 |

Typical All Weld Metal Mechanical Properties(As Welded)

典型全焊缝金属机械性能(焊态):

Ultimate Tensile Strength抗拉强度:650 N/mm2

0.2% Proof Stress屈服强度: 420 N/mm2

Sizes Available and Recommended Amperages

尺寸Φ/电流:

2.5mm | 3.2mm | 4.0mm |

60-90A | 80-120A | 130-170A |

Current电流:AC/DC (+) AC (OCV 80) Min

Related Specification参考标准:AWS A5.4 E320LR-16

Storage储存:Electrodes should be stored in dry conditions. Should the electrodes become damp, re-dry for one hour at 150°C before use. 焊条应储存在干燥环境中。如果焊条受潮,应在150°C下重新干燥1小时后再使用。