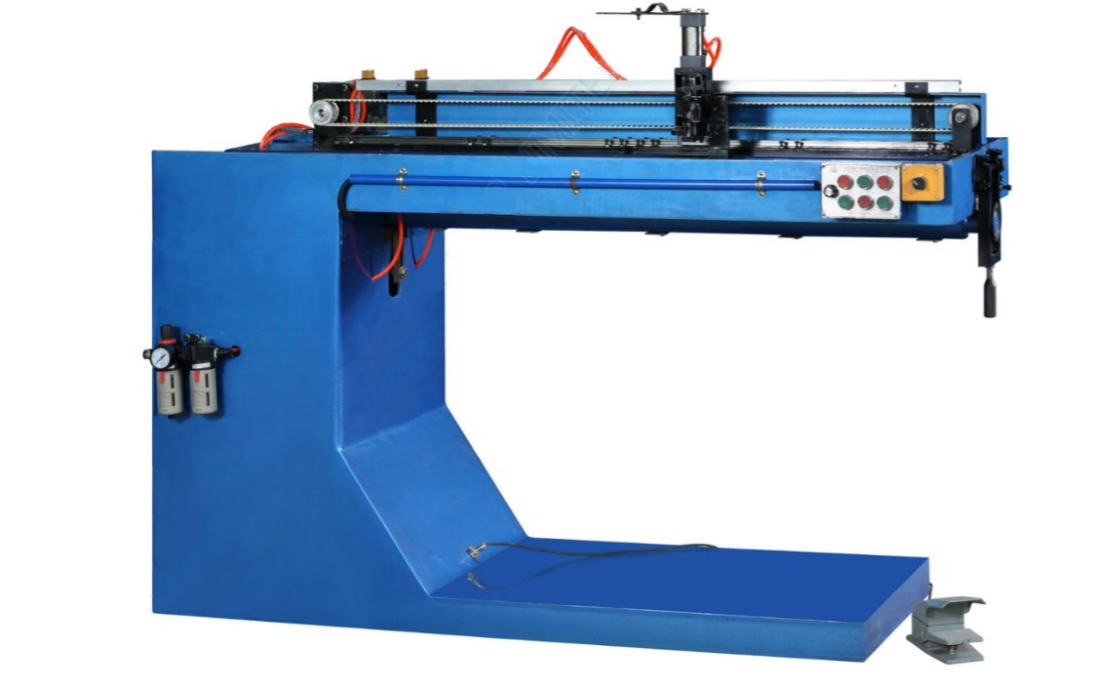

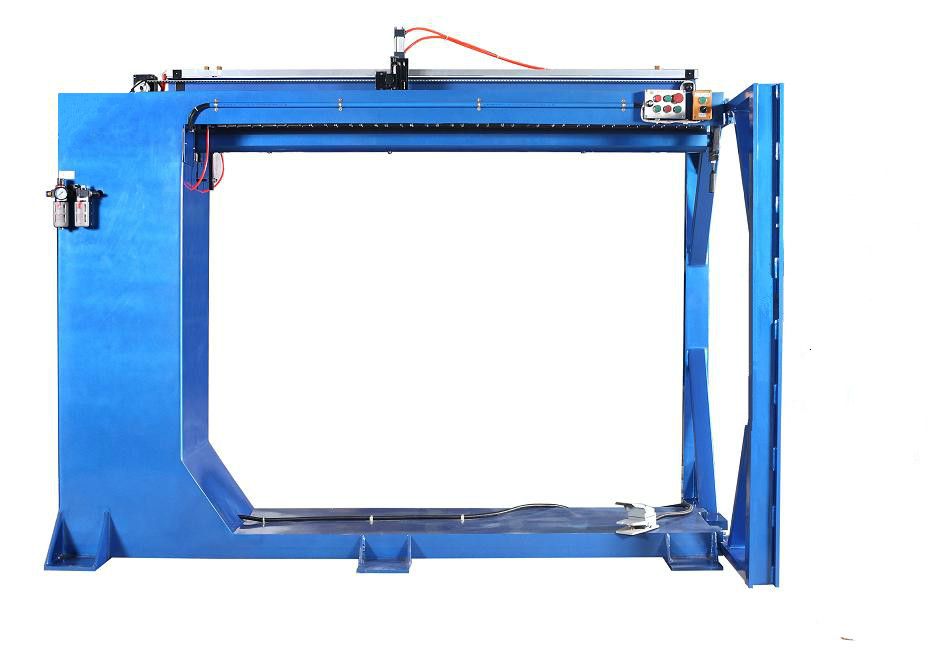

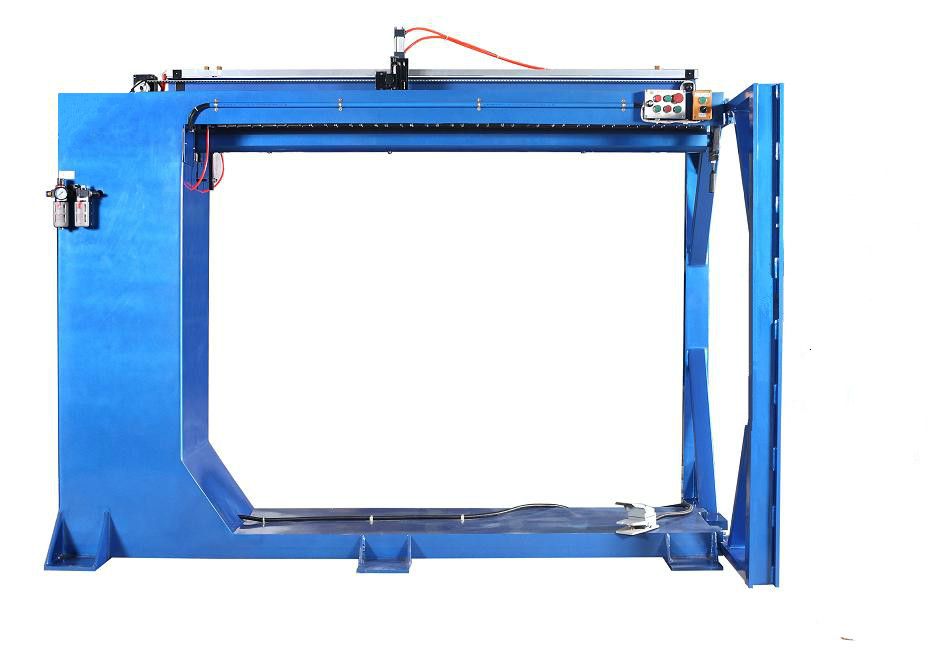

整机特性:

1 本机采用琴键式铜合金压紧机构,提供均匀稳定的工件夹持和冷却效果;

2. 配备焊缝背面保护衬套和成型槽,以保证提供稳定的气体保护和确保达到单面焊接双面成型的好效果;

3.本机可按要求选用PLC或继电器集成控制;

4. 焊枪行走采用直流电机驱动,焊接速度无级可调;

5. 可任意匹配各种类型弧焊电源(氩弧焊/CO2焊/等离子弧焊);

6.设备设计人性化, 只需普通工人操作即可,为工厂解决招工难招焊工师傅更难,生产效率低等问题;

7.自动直缝焊接主要用于不锈钢、铁、铝、黄铜等各种金属的圆筒、拼板的高质量、低变形的直线性自动焊接.

Main Features and

Applications

1.Adopted

keyboard type copper pressing mechanism, to get the regular and stable clamping

and cooling effect;

2. Special designed back protective copper

block and molding slot, to assure the stable gas shield and achieve double side

forming

in single side welding;

3.Machine can adopt PLC or Relay

integrated control as requirement;

4. Torch moving driven by DC motor , welding

speed stepless adjustable;

5.Apply to cooperate welding with TIG,

MIG, MAG and Plasma-Arc welding source;

6.Equipment design humane, just ordinary

workers can be, for the factory to solve the recruitment difficult to recruit

welding

master more difficult, low production

efficiency issues;

7.Automatic TIG(Plasma) Longitudinal Seam

Welding Machine is mainly used for the high quality and low

distortion automatic

longitudinal welding of the metallic

cylinders and aligned plates made with stainless steel, iron, aluminum and

brass, etc.

主要技术参数 Main Technical Parameters

型号 Model

项目Item | TZF-300 | TZF-500 | TZF-800 | TZF-1000 | TZF-1200 | TZF-1500 | TZF-2000 |

输入电压 Input

voltage | Single

Phase 220V,

50/60Hz |

极大焊接长度(mm)

Max welding length | 300mm | 500mm | 800mm | 1000mm | 1200mm | 1500mm | 2000mm |

工件直径 (mm)

Workpiece diameter | 50-800mm | 70-800mm | 90-800mm | 100-800mm | 100-800mm | 120-800mm | 180-800mm |

适用厚度 Workpiece

thickness | 0.3-3mm | 0.4-3mm |

焊接速度 Welding

Speed | 300-2000mm/min |