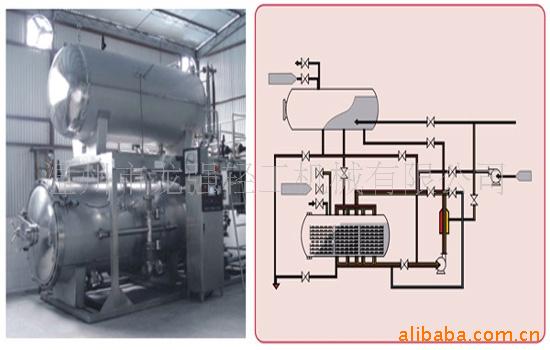

热水回转式杀菌釜是由工艺罐、热水罐、泵及连拉管道、PLC和触摸屏组成的自动控制系统构成。采用高温高压的热水做为加热介质,可对复合薄膜包培育、结扎肠衣包装、塑料盒包装、三片罐、易拉罐、玻璃瓶、塑料袋等多种包装的食品进行高温快速菌处理,食品在装置内连续缓慢回转,使其热传递更迅速均匀,大大缩短整个杀菌过程的时间,从而达到高温短时杀菌处理。该机的特点是:

1、回转方式,可避免食品周围产生过热现象

2、温度控制系统可灵活地根据不同包装物特点进行自动控制。

3、压务控制系统配合标准模式自动调整压力,根据不同情况,进行反压较正,这对防止容器的变形和破损,提高成品率十分有利。

4、通过对T-t,P-t记录曲线的分析和检查,可以有效地进行生产和品质管理。

5、锅体等主要件和与物料相接触的主要件均用优质不锈钢制造,设备符合食品卫生要求。

1. Pouring type Water Retort Sterilizer Working Principles

Pouring type Water Retort Sterilizer adopts high temperature and pressure hot water pouring over various of food packages to achieve instant sterilization result. During the process, food is poured by hot water( cold water) rapidly, and temperature is evenly distributed, which is critical to products quality, productivity and energy saving, and also can avoid over-heating.

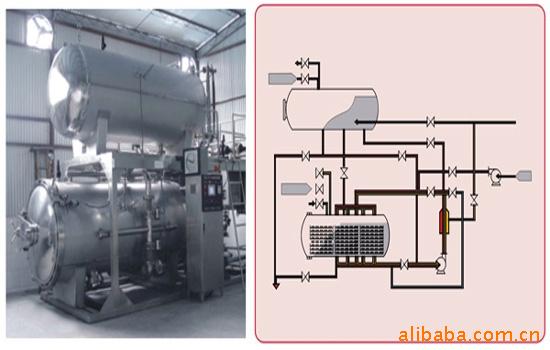

2. Pouring type Water Retort Sterilizer Control System

1) Pouring type Water Retort Sterilizer adopts analog temperature control system, pre-set heating and cooling program according to different food sterilization requirements to ensure each kind of food can be sterilized under the most suitable conditions, which can avoid over heating damage caused by high temperature and pressure. Pressure control system works with standard modes to adjust pressure atuomatically under different situations, which can avoid packages deformation and damage. Meanwhile, through the analysis to the T-t and P-t curve record can effectively manage production and quality. All the operations are carried out automatically according to the programs pre-setted by operator.

2) The control panel is consist of three parts stated below:

-- Touch Screen: the sterilizer working conditions can be noted anytime through the flow chart on the Touch Screen. Under manual status, each pneumatic valve and pump can be operated by pressing the specific graphic button on the Touch Screen.

-- Micro program controller: different sterilization parameters can be easily input through the Touch Screen setting window. There are over 200 different sterilization programs saved in the computer, and each program is consist of 19 steps, meeting different sterilization requirements.

-- Paperless Recorder: to record the data of temperature, time, pressure and sterilization F value.

3. Specifications we provide:

DN1500, rotary type, capicity: 1-5 baskets

Manual, Semi-automatic and Fully-automatic for options.

4. Applicable products

Regular sealed cans, Vacuum cans, Bottle cans, Aluminum packages, and Plastic packages.