小直径内孔加工的优越性能

特征

最小加工直径Ø4.5mm

有钢和硬质合金刀杆

有直柄径刀杆

可使用内冷却

容屑槽设计实现优越的排屑性能

方便安装的悬伸量刻度

通过有限元素分析法改进刚性设计,减少让刀和振动

增加了“Z”形刀杆,实现内径反车加工

应用范围广

有小机床用套筒选择

有密封盖提供选择

特殊的套筒设计,精确控制外冷却

稳定的刀具寿命和卓越的切屑控制性能

W08 断屑槽

超细微粒硬质合金保证了锋利的切削刃

两种材质选择SH730(通用),TH10(非铁合金)

刀片型号“ EPGT04” 和“ WBGT03” 新增R0.1刀尖圆弧

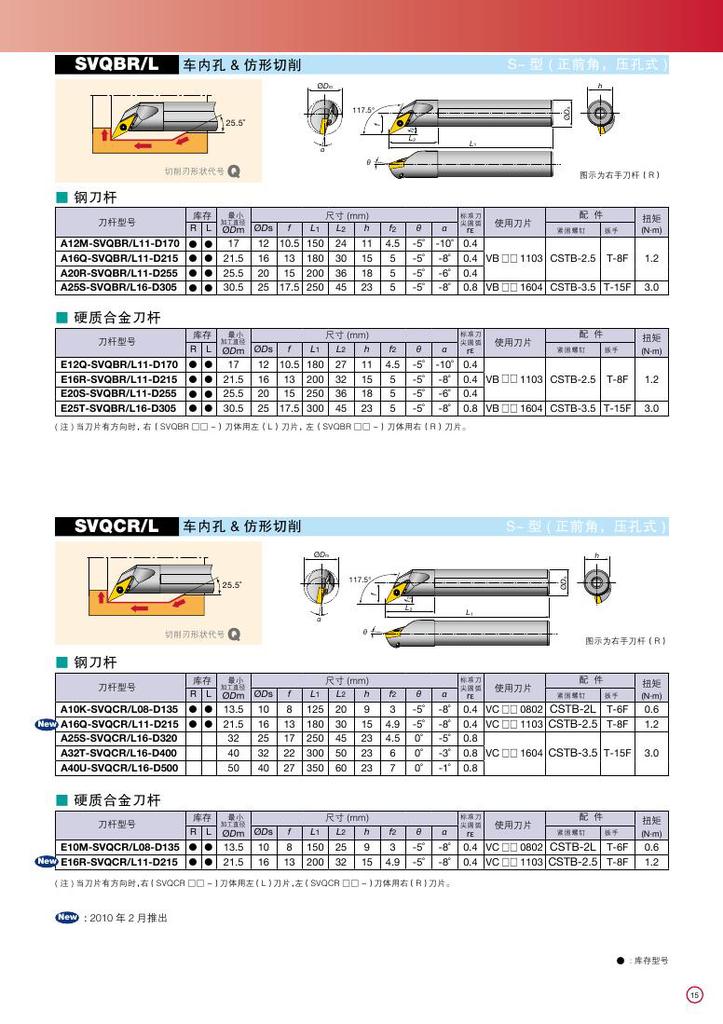

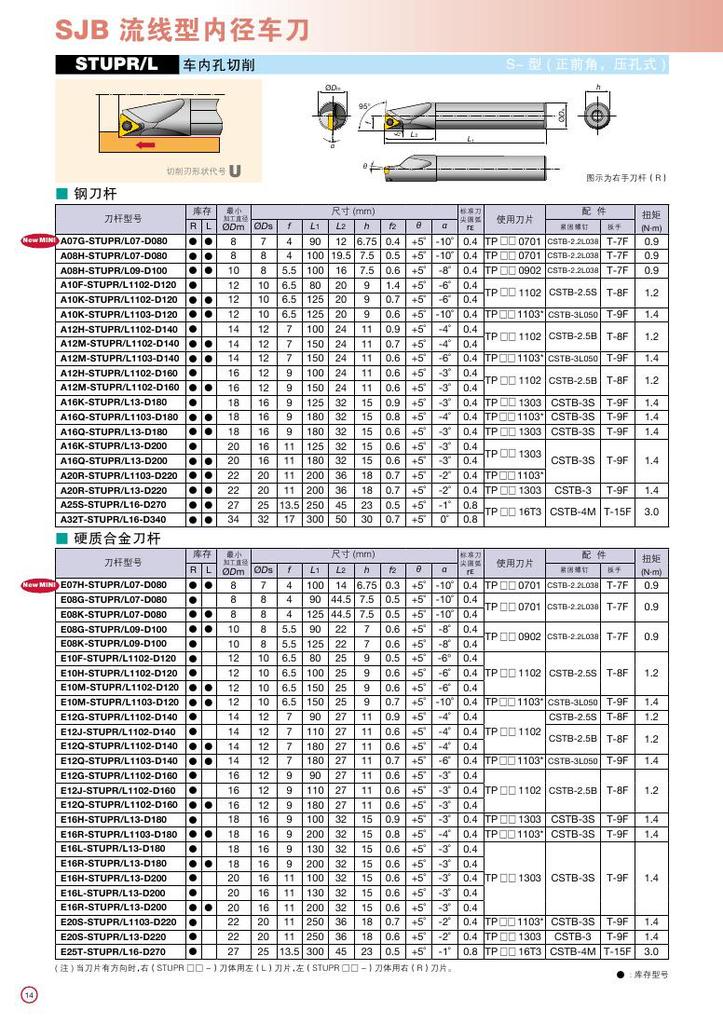

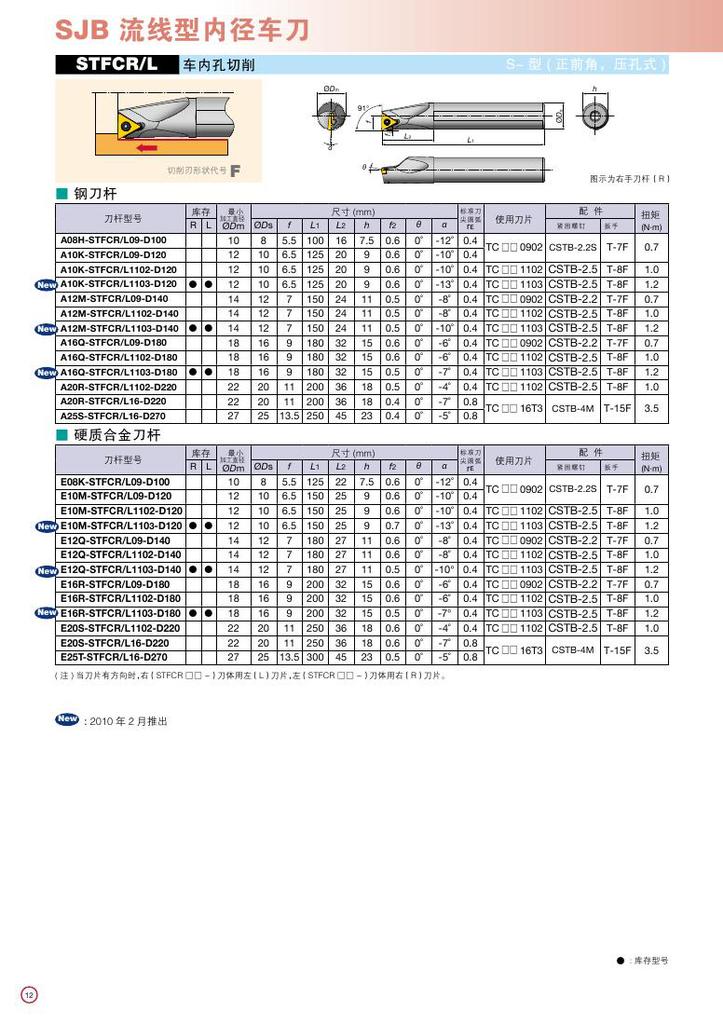

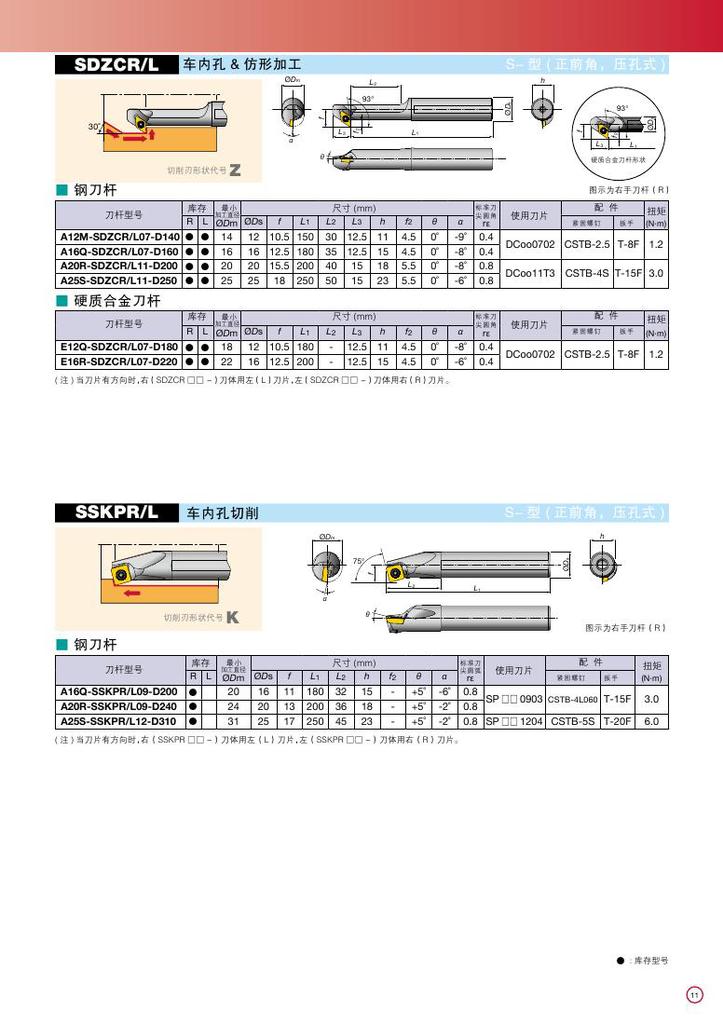

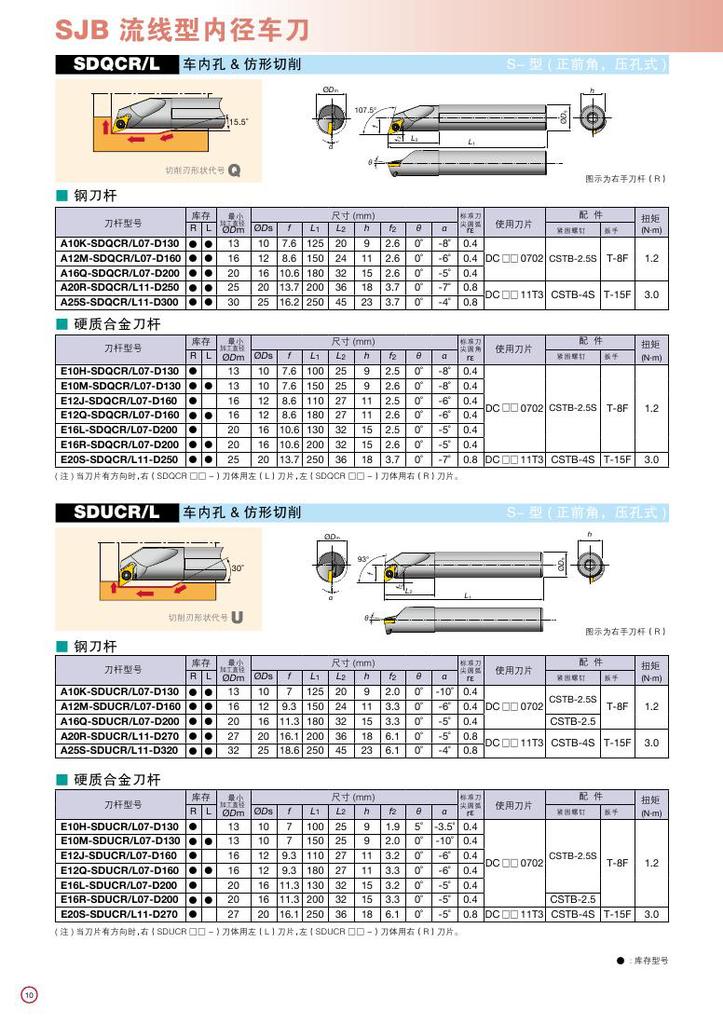

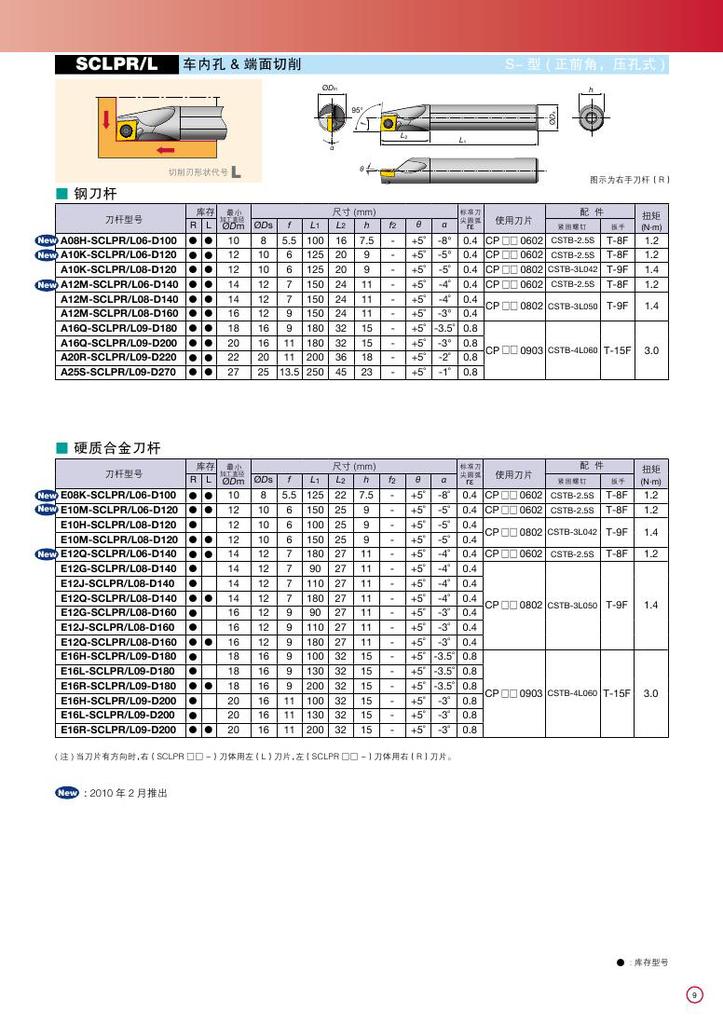

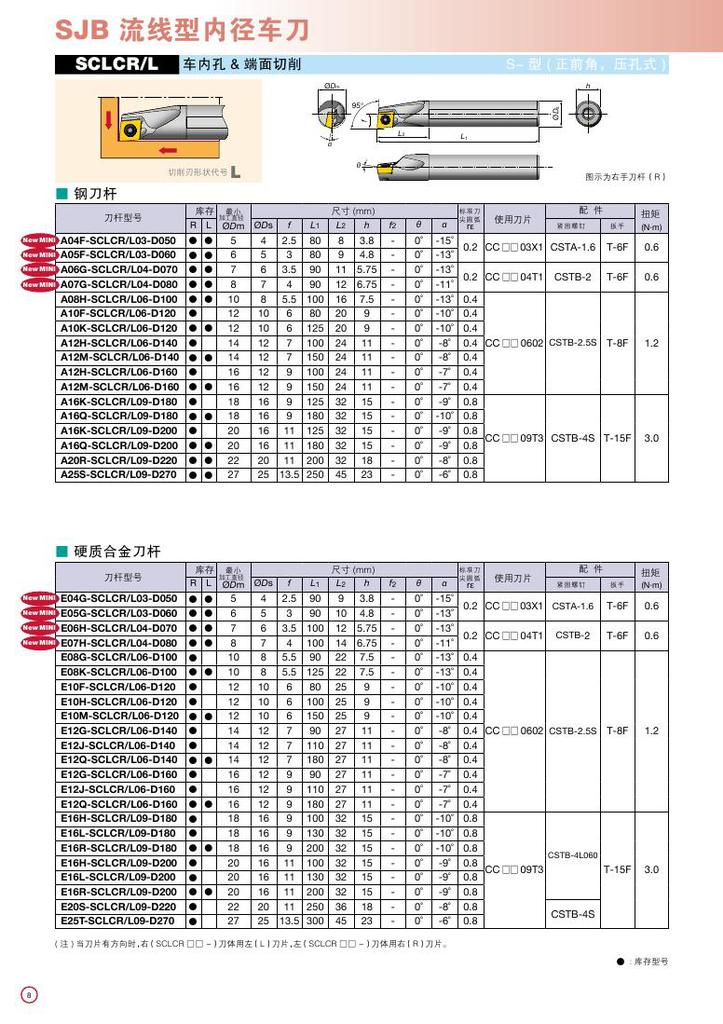

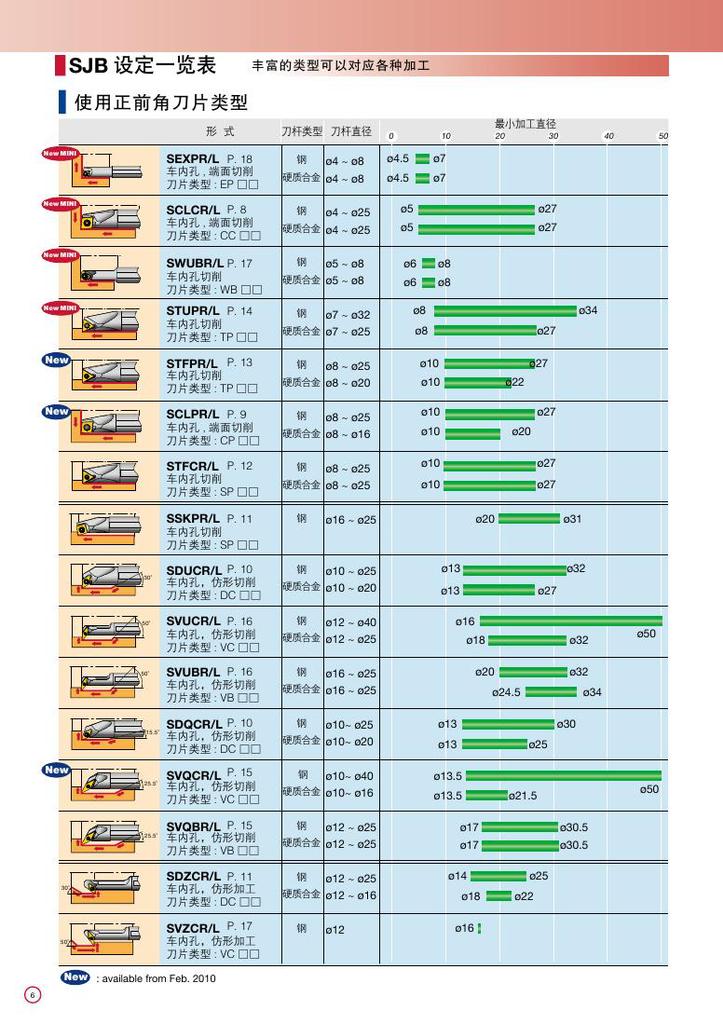

No.357-CNo.357-CTAC内径车刀SJB系列流线型内冷却内径车刀扩充NEW!!全新的“MINI”系列,专为小直径内孔加工设计!具有优良切屑排出性的高刚性内径车刀杆SJB流线型内径车刀1性能提升通过大量的模拟分析,Tungaloy开发了具有高刚性的流线型内冷却内径车刀-SJB系列,其完美的几何构造,实现了优越的排屑性能小直径内孔加工的优越性能最小加工直径.4.5mm有钢和硬质合金刀杆有直柄径刀杆可使用内冷却容屑槽设计实现优越的排屑性能方便安装的悬伸量刻度通过有限元素分析法改进刚性设计,减少让刀和振动增加了“Z”形刀杆,实现内径反车加工特征全新的“MINI”系列,专为小直径内孔加工设计容屑槽冷却孔NewMINI2应用范围广有小机床用套筒选择有密封盖提供选择特殊的套筒设计,精确控制外冷却(见图)New密封盖*(可选)螺钉(MG)注意:请用工具调整密封盖,使同轴度一致3稳定的刀具寿命和卓越的切屑控制性能W08断屑槽超细微粒硬质合金保证了锋利的切削刃两种材质选择SH730(通用),TH10(非铁合金)刀片型号“EPGT04”和“WBGT03”新增R0.1刀尖圆弧2*配件:2010年2月可提供l解析负荷传导路径SJB系列状态普通刀杆状态对刀杆刚性影响小的地方提升切屑排出性对刀杆刚性影响大的地方追求高刚性l解析负荷传导路径SJB系列状态普通刀杆状态对刀杆刚性影响小的地方提升切屑排出性对刀杆刚性影响大的地方追求高刚性提升刀体刚性,抑制弯曲和振动l与以往刀体的刚性对比使刀头最厚的部分尽可能接近刀尖,由于这个改进,与以往相比主分力方向的刚性大副提升负载:1000N(假设Vc=150m/min,ap=1.5mm,f=0.2mm/rev)A16Q-STUPR13-D180与以往相比减少了约20%的弯曲量SJB系列以往产品剖面小剖面大保持厚的刀片座处的形状,高刚性和切屑排出性能俱佳的最适合形状。排屑方向普通刀杆容易积留碎屑SJB系列排屑方向结合精心设计的容屑槽设计,冷却液携带铁屑快速的排出。弯曲弯曲断排屑性能卓越的排屑槽形状l切削性能有良好的断排屑性能,可以有效抑制由于碎屑的夹杂或卷缠引起的刀具损伤,同时也可以防止碎屑损坏工件。尽可能接近刀尖,改善切削油供给的油孔设计。l油孔位置使刀尖和油孔的距离最小化(与本公司同类产品相比减少1/2)l油孔螺钉*当不使用内冷却时,可用螺钉封住油孔防止铁屑堵塞(可选)*只有负前角刀具型号3延长刀具寿命通过最恰当的切削液供给,有效抑制刀具的磨损,达到延长刀具寿命的目的。0.200.150.100.05切削时间(min)其它公司刀杆SJB系列051015202530使用方便刻标记规格刀尖部分后刀面磨损(mm)刀杆:A16Q-STUPR1103-D180刀片:TPMT110304-PS(GT730)被加工材料:S45C(220HB):孔径(.30~50mm)切削速度:Vc=100m/min切深:ap=0.5mm进给:f=0.2mm/rev切削液:水溶性切削液刀杆型号刀杆编号的最后一组字母和数字表示最小可加工孔的直径。(例如)-D14014.0mm适用螺钉型号悬伸量刻度适用刀片型号螺钉遗失及其它情况下,节省烦锁的型安装刀杆时方便操作。适用刀片的型号一目了然,刀具管号确认过程。理更简单。硬质合金刀杆高钢性硬质合金刀杆和高钢性钢刀头,进一步提升刚性以及实现卓越切屑排出性。悬伸比例L/DL/D 3L/D 5钢刀杆硬质合金刀杆≤≤更高精度卓越的切屑处理性能,顺畅的排出切屑,抑制工件损伤;提升刚性,抑制振动,实现优良的加工表面,保证尺寸精度。L:悬伸长度,D:刀杆直径4SJB流线型内径车刀TAC内孔车刀的表示方法829105674TUPSAM-R1102D1401312ABCDEFSVUX*YZGJKLNP*Q*90°75°90°45°60°91°91°91°93°75°95°95°63°62.5°45°45°72.5°93°100°80°CBNPRL........STCR140.14.0mm7°5°0°11°CDESTVYW代号形状无无无无无无无无无有有有有有无有有有无注:有“*”标记为Tungaloy代号。无“*”标记为ISO代号。偏移FGHJKLMPQRSTUAE80901001101251301501701802002503003508910123S6754L1P侧推式压孔式在ISO公制体系中,用刀片一边的长度(2位数)表示。如果边尺寸相同,将会把厚度代号也表示出来。以上述型号为例,刀片使用。SJB系有内冷却孔钢刀杆有内冷却孔硬质合金刀杆(带钢刀头)刀杆的直径用mm表示车刀方向代号刀片尺寸代号(S)最小加工孔径刀杆形式代号刀杆直径刀杆长度代号L1(mm)切削刀形状刀片后角代号刀片形状代号夹紧方式ISO标准M.S.C型Inaboveexample,TPoo1102ooRS菱形80°菱形55°菱形75°正方形正三角形菱形35°特殊六边形多边形25°(泰珂洛标准)5SJB设定一览表使用正前角刀片类型最小加工直径形式刀杆类型刀杆直径NewNewNewMININewMININewMININewMINI丰富的类型可以对应各种加工01020304050SEXPR/LP.18车内孔,端面切削刀片类型:EP□□钢硬质合金.4~.8.4~.8.4.5.7.4.5.7SCLCR/LP.8车内孔,端面切削刀片类型:CC□□钢硬质合金.4~.25.4~.25.5.27.5.27SWUBR/LP.17车内孔切削刀片类型:WB□□钢硬质合金.5~.8.5~.8.6.8.6.8STUPR/LP.14车内孔切削刀片类型:TP□□钢硬质合金.7~.32.7~.25.8.34.8.27STFPR/LP.13车内孔切削刀片类型:TP□□钢硬质合金.8~.25.8~.20.10 .27.10 .22SCLPR/LP.9车内孔,端面切削刀片类型:CP□□钢硬质合金.8~.25.8~.16.10.27.10.20STFCR/LP.12车内孔切削刀片类型:SP□□钢硬质合金.8~.25.8~.25.10.27.10.27SSKPR/LP.11车内孔切削刀片类型:SP□□钢.16~.25.20.3130°SDUCR/LP.10车内孔,仿形切削刀片类型:DC□□钢硬质合金.10~.25.10~.20.13.32.13.2750°SVUCR/LP.16车内孔,仿形切削刀片类型:VC□□钢硬质合金.12~.40.12~.25.16.18.32.5050°SVUBR/LP.16车内孔,仿形切削刀片类型:VB□□钢硬质合金.16~.25.16~.25.20.32.24.5.3415.5°SDQCR/LP.10车内孔,仿形切削刀片类型:DC□□钢硬质合金.10~.25.10~.20.13.30.13.2525.5°SVQCR/LP.15车内孔,仿形切削刀片类型:VC□□钢硬质合金.10~.40.10~.16.13.5.13.5.21.5.5025.5°SVQBR/LP.15车内孔,仿形切削刀片类型:VB□□钢硬质合金.12~.25.12~.25.17.30.5.17.30.530°SDZCR/LP.11车内孔,仿形加工刀片类型:DC□□钢硬质合金.12~.25.12~.16.14.25.18.2250°SVZCR/LP.17车内孔,仿形加工刀片类型:VC□□钢.12.166NewNew:availablefromFeb.2010使用正前角刀片SVJCR/LSVJBR/LSYQBR/LSYUBR/L30°60°01020304050SEZPR/LSVZBR/L50°.16~.32.4~.5.4~.5.12~.16.20~.25.12~.16.12~.16.16.12~.16.20 .40.5.5.6.5.5.5.6.5.16.20.25.30.17.21.5.17.21.5.20.20.24.5NewMINIP.16车内孔仿形加工刀片类型:VB□□P.17车内孔加工刀片类型:EP□□P.18,19车内孔球面加工刀片类型:VC□□P.18,19车内孔球面加工刀片类型:VB□□P.20车内孔仿形切削刀片类型:YW□□P.20车内孔仿形切削刀片类型:YW□□钢钢硬质合金钢钢钢硬质合金钢硬质合金形式刀杆类型刀杆直径最小加工直径使用负前角刀片类型PDZNR/LPWLNR/LPTFNR/LPDUNR/LPVUNR/LPTUNR/LPCLNR/LPSKNR/L50°010203040506070.16~.32.25~.50.32~.50.20~.50.16~.50.16~.40.25~.40.32~.50.20.40.32.63.40.63.25.63.20.63.20.50.37.50 .40.63P.22车内孔切削刀片类型:TN□□P.22车内孔切削刀片类型:TN□□P.22车内孔切削刀片类型:SN□□P.21车内径仿形切削刀片类型:DN□□P.21车内径端面切削刀片类型:CN□□P.23车内径端面切削刀片类型:WN□□P.23车内径仿形切削刀片类型:VN□□P.21车内反车内孔切削刀片类型:DN□□钢钢钢钢钢钢钢钢形式刀杆类型刀杆直径最小加工直径SJB流线型内径车刀SCLCR/L车内孔&端面切削S-型(正前角,压孔式).Dmhα95°fL1L2.Ds Lθ切削刃形状代号L图示为右手刀杆(R)■钢刀杆.Dmrε(N·m)RL.DsfL1L2hf2θαA04F-SCLCR/L03-D050●●542.58083.8-0.-15.0.2CC□□03X1CSTA-1.6T-6F0.6A05F-SCLCR/L03-D060●●6538094.8-0.-13.A06G-SCLCR/L04-D070●●763.590115.75-0.-13.0.2CC□□04T1CSTB-2T-6F0.6A07G-SCLCR/L04-D080●●87490126.75-0.-11.A08H-SCLCR/L06-D100●●1085.5100167.5-0.-13.0.4CC□□0602CSTB-2.5ST-8F1.2A10F-SCLCR/L06-D120●1210680209-0.-10.0.4A10K-SCLCR/L06-D120●●12106125209-0.-10.0.4A12H-SCLCR/L06-D140●141271002411-0.-8.0.4A12M-SCLCR/L06-D140●●141271502411-0.-8.0.4A12H-SCLCR/L06-D160●161291002411-0.-7.0.4A12M-SCLCR/L06-D160●●161291502411-0.-7.0.4A16K-SCLCR/L09-D180●181691253215-0.-9.0.8CC□□09T3CSTB-4ST-15F3.0A16Q-SCLCR/L09-D180●●181691803215-0.-10.0.8A16K-SCLCR/L09-D200●2016111253215-0.-9.0.8A16Q-SCLCR/L09-D200●●2016111803215-0.-9.0.8A20R-SCLCR/L09-D220●●2220112003218-0.-8.0.8A25S-SCLCR/L09-D270●●272513.52504523-0.-6.0.8配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径使用刀片标准刀尖圆弧扭矩NewMININewMININewMININewMINI■硬质合金刀杆.Dmrε(N·m)RL.DsfL1L2hf2θαE04G-SCLCR/L03-D050●●542.59093.8-0.-15.0.2CC□□03X1CSTA-1.6T-6F0.6E05G-SCLCR/L03-D060●●65390104.8-0.-13.E06H-SCLCR/L04-D070●●763.5100125.75-0.-13.0.2CC□□04T1CSTB-2T-6F0.6E07H-SCLCR/L04-D080●●874100146.75-0.-11.E08G-SCLCR/L06-D100●1085.590227.5-0.-13.0.4CC□□0602CSTB-2.5ST-8F1.2E08K-SCLCR/L06-D100●●1085.5125227.5-0.-13.0.4E10F-SCLCR/L06-D120●1210680259-0.-10.0.4E10H-SCLCR/L06-D120●12106100259-0.-10.0.4E10M-SCLCR/L06-D120●●12106150259-0.-10.0.4E12G-SCLCR/L06-D140●14127902711-0.-8.0.4E12J-SCLCR/L06-D140●141271102711-0.-8.0.4E12Q-SCLCR/L06-D140●●141271802711-0.-8.0.4E12G-SCLCR/L06-D160●16129902711-0.-7.0.4E12J-SCLCR/L06-D160●161291102711-0.-7.0.4E12Q-SCLCR/L06-D160●●161291802711-0.-7.0.4E16H-SCLCR/L09-D180●181691003215-0.-10.0.8CC□□09T3CSTB-4L060T-15F3.0E16L-SCLCR/L09-D180●181691303215-0.-10.0.8E16R-SCLCR/L09-D180●●181692003215-0.-10.0.8E16H-SCLCR/L09-D200●2016111003215-0.-9.0.8E16L-SCLCR/L09-D200●2016111303215-0.-9.0.8E16R-SCLCR/L09-D200●●2016112003215-0.-9.0.8E20S-SCLCR/L09-D220●2220112503618-0.-8.0.8CSTB-4SE25T-SCLCR/L09-D270●272513.53004523-0.-6.0.8配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径使用刀片标准刀尖圆弧扭矩NewMININewMININewMININewMINI8(注)当刀片有方向时,右(SCLCR□□-)刀体用左(L)刀片,左(SCLCR□□-)刀体用右(R)刀片。●:库存型号SCLPR/Lh车内孔&端面切削S-型(正前角,压孔式).Dmα切削刃形状代号Lθ95°L1L2图示为右手刀杆(R)■钢刀杆f.Ds.Dmrε(N·m)RL.DsfL1L2hf2θαA08H-SCLPR/L06-D100●●1085.5100167.5-+5.-8°0.4CP□□0602CSTB-2.5ST-8F1.2A10K-SCLPR/L06-D120●●12106125209-+5.-5°0.4CP□□0602CSTB-2.5ST-8F1.2A10K-SCLPR/L08-D120●●12106125209-+5.-5.0.4CP□□0802CSTB-3L042T-9F1.4A12M-SCLPR/L06-D140●●141271502411-+5.-4.0.4CP□□0602CSTB-2.5ST-8F1.2A12M-SCLPR/L08-D140●●141271502411-+5.-4.0.4CP□□0802CSTB-3L050T-9F1.4A12M-SCLPR/L08-D160●●161291502411-+5.-3°0.4A16Q-SCLPR/L09-D180●●181691803215-+5.-3.5.0.8CP□□0903CSTB-4L060T-15F3.0A16Q-SCLPR/L09-D200●●2016111803215-+5.-3°0.8A20R-SCLPR/L09-D220●●2220112003618-+5.-2.0.8A25S-SCLPR/L09-D270●●272513.52504523-+5.-1.0.8配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径使用刀片标准刀尖圆弧扭矩NewNewNew■硬质合金刀杆.Dmrε(N·m)RL.DsfL1L2hf2θαE08K-SCLPR/L06-D100●●1085.5125227.5-+5.-8.0.4CP□□0602CSTB-2.5ST-8F1.2E10M-SCLPR/L06-D120●●12106150259-+5.-5.0.4CP□□0602CSTB-2.5ST-8F1.2E10H-SCLPR/L08-D120●12106100259-+5.-5.0.4CP□□0802CSTB-3L042T-9F1.4E10M-SCLPR/L08-D120●●12106150259-+5.-5.0.4E12Q-SCLPR/L06-D140●●141271802711-+5.-4.0.4CP□□0602CSTB-2.5ST-8F1.2E12G-SCLPR/L08-D140●14127902711-+5.-4.0.4CP□□0802CSTB-3L050T-9F1.4E12J-SCLPR/L08-D140●141271102711-+5.-4.0.4E12Q-SCLPR/L08-D140●●141271802711-+5.-4.0.4E12G-SCLPR/L08-D160●16129902711-+5.-3.0.4E12J-SCLPR/L08-D160●161291102711-+5.-3.0.4E12Q-SCLPR/L08-D160●●161291802711-+5.-3.0.4E16H-SCLPR/L09-D180●181691003215-+5.-3.5.0.8CP□□0903CSTB-4L060T-15F3.0E16L-SCLPR/L09-D180●181691303215-+5.-3.5.0.8E16R-SCLPR/L09-D180●●181692003215-+5.-3.5.0.8E16H-SCLPR/L09-D200●2016111003215-+5.-3.0.8E16L-SCLPR/L09-D200●2016111303215-+5.-3.0.8E16R-SCLPR/L09-D200●●2016112003215-+5.-3.0.8配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径使用刀片标准刀尖圆弧扭矩NewNewNew(注)当刀片有方向时,右(SCLPR□□-)刀体用左(L)刀片,左(SCLPR□□-)刀体用右(R)刀片。NewNew:2010年2月推出●:库存型号9L2107.5°ff2L1.DsL2107.5°ff2L1.DsSJB流线型内径车刀SDQCR/L车内孔&仿形切削S-型(正前角,压孔式)15.5°.Dmh θ切削刃形状代号Q图示为右手刀杆(R)■钢刀杆刀杆型号库存.Dm最小加工直径尺寸(mm)rε标准刀尖圆弧使用刀片配件(N·m)扭矩RL.DsfL1L2hf2θα紧固螺钉扳手A10K-SDQCR/L07-D130●●13107.61252092.60.-8.0.4DC□□0702CSTB-2.5ST-8F1.2A12M-SDQCR/L07-D160●●16128.615024112.60.-6.0.4A16Q-SDQCR/L07-D200●●201610.618032152.60.-5.0.4A20R-SDQCR/L11-D250●●252013.720036183.70.-7.0.8DC□□11T3CSTB-4ST-15F3.0A25S-SDQCR/L11-D300●●302516.225045233.70.-4.0.8■硬质合金刀杆刀杆型号库存.Dm最小加工直径尺寸(mm)rε标准刀尖圆角使用刀片配件(N·m)扭矩RL.DsfL1L2hf2θα紧固螺钉扳手E10H-SDQCR/L07-D130●13107.61002592.50.-8.0.4DC□□0702CSTB-2.5ST-8F1.2E10M-SDQCR/L07-D130●●13107.61502592.60.-8.0.4E12J-SDQCR/L07-D160●16128.611027112.50.-6.0.4E12Q-SDQCR/L07-D160●●16128.618027112.60.-6.0.4E16L-SDQCR/L07-D200●201610.613032152.50.-5.0.4E16R-SDQCR/L07-D200●●201610.620032152.60.-5.0.4E20S-SDQCR/L11-D250●●252013.725036183.70.-7.0.8DC□□11T3CSTB-4ST-15F3.0(注)当刀片有方向时,右(SDQCR□□-)刀体用左(L)刀片,左(SDQCR□□-)刀体用右(R)刀片。SDUCR/L车内孔&仿形切削S-型(正前角,压孔式)30°αh.Dmf2L2L193°f.Ds切削刃形状代号Uθ图示为右手刀杆(R)■钢刀杆刀杆型号库存.Dm最小加工直径尺寸(mm)rε标准刀尖圆弧使用刀片配件(N·m)扭矩RL.DsfL1L2hf2θα紧固螺钉扳手A10K-SDUCR/L07-D130●●131071252092.00.-10.0.4DC□□0702CSTB-2.5ST-8F1.2A12M-SDUCR/L07-D160●●16129.315024113.30.-6.0.4A16Q-SDUCR/L07-D200●●201611.318032153.30.-5.0.4CSTB-2.5A20R-SDUCR/L11-D270●●272016.120036186.10.-5.0.8DC□□11T3CSTB-4ST-15F3.0A25S-SDUCR/L11-D320●●322518.625045236.10.-4.0.8■硬质合金刀杆刀杆型号库存.Dm最小加工直径尺寸(mm)rε标准刀尖圆弧使用刀片配件(N·m)扭矩RL.DsfL1L2hf2θα紧固螺钉扳手E10H-SDUCR/L07-D130●131071002591.95.-3.5.0.4DC□□0702CSTB-2.5ST-8F1.2E10M-SDUCR/L07-D130●●131071502592.00.-10.0.4E12J-SDUCR/L07-D160●16129.311027113.20.-6.0.4E12Q-SDUCR/L07-D160●●16129.318027113.30.-6.0.4E16L-SDUCR/L07-D200●201611.313032153.20.-5.0.4E16R-SDUCR/L07-D200●●201611.320032153.30.-5.0.4CSTB-2.5E20S-SDUCR/L11-D270●272016.125036186.10.-5.0.8DC□□11T3CSTB-4ST-15F3.010(注)当刀片有方向时,右(SDUCR□□-)刀体用左(L)刀片,左(SDUCR□□-)刀体用右(R)刀片。●:库存型号SDZCR/L车内孔&仿形加工S-型(正前角,压孔式).DmhL230°αL1L3.Dsf93°f2θ切削刃形状代号ZL1L3.Dsf93°f2硬质合金刀杆形状■钢刀杆图示为右手刀杆(R)刀杆型号库存.Dm最小加工直径尺寸(mm)rε标准刀尖圆角使用刀片配件(N·m)扭矩RL.DsfL1L2L3hf2θα紧固螺钉扳手A12M-SDZCR/L07-D140●●141210.51503012.5114.50.-9.0.4DCoo0702CSTB-2.5T-8F1.2A16Q-SDZCR/L07-D160●●161612.51803512.5154.50.-8.0.4A20R-SDZCR/L11-D200●●202015.52004015185.50.-8.0.8DCoo11T3CSTB-4ST-15F3.0A25S-SDZCR/L11-D250●●2525182505015235.50.-6.0.8■硬质合金刀杆刀杆型号库存.Dm最小加工直径尺寸(mm)rε标准刀尖圆角使用刀片配件(N·m)扭矩RL.DsfL1L2L3hf2θα紧固螺钉扳手E12Q-SDZCR/L07-D180●●181210.5180-12.5114.50.-8.0.4DCoo0702CSTB-2.5T-8F1.2E16R-SDZCR/L07-D220●●221612.5200-12.5154.50.-6.0.4(注)当刀片有方向时,右(SDZCR□□-)刀体用左(L)刀片,左(SDZCR□□-)刀体用右(R)刀片。SSKPR/LS-型(正前角,压孔式)车内孔切削.Dmh75°fL2L1.Dsα切削刃形状代号Kθ图示为右手刀杆(R)■钢刀杆刀杆型号库存.Dm最小加工直径尺寸(mm)rε标准刀尖圆弧使用刀片配件(N·m)扭矩RL.DsfL1L2hf2θα紧固螺钉扳手A16Q-SSKPR/L09-D200●2016111803215-+5.-6.0.8SP□□0903CSTB-4L060T-15F3.0A20R-SSKPR/L09-D240●2420132003618-+5.-2.0.8A25S-SSKPR/L12-D310●3125172504523-+5.-2.0.8SP□□1204CSTB-5ST-20F6.0(注)当刀片有方向时,右(SSKPR□□-)刀体用左(L)刀片,左(SSKPR□□-)刀体用右(R)刀片。●:库存型号11SJB流线型内径车刀STFCR/L车内孔切削S-型(正前角,压孔式).Dmh .Dsf2L1L291°f切削刃形状代号Fθ图示为右手刀杆(R)■钢刀杆.Dmrε(N·m)RL.DsfL1L2hf2θαA08H-STFCR/L09-D1001085.5100167.50.60.-12.0.4TC□□0902CSTB-2.2ST-7F0.7A10K-STFCR/L09-D12012106.51252090.60.-10.0.4A10K-STFCR/L1102-D12012106.51252090.60.-10.0.4TC□□1102CSTB-2.5T-8F1.0A10K-STFCR/L1103-D120●●12106.51252090.60.-13.0.4TC□□1103CSTB-2.5T-8F1.2A12M-STFCR/L09-D1401412715024110.50.-8.0.4TC□□0902CSTB-2.2T-7F0.7A12M-STFCR/L1102-D1401412715024110.50.-8.0.4TC□□1102CSTB-2.5T-8F1.0A12M-STFCR/L1103-D140●●1412715024110.50.-10.0.4TC□□1103CSTB-2.5T-8F1.2A16Q-STFCR/L09-D1801816918032150.60.-6.0.4TC□□0902CSTB-2.2T-7F0.7A16Q-STFCR/L1102-D1801816918032150.60.-6.0.4TC□□1102CSTB-2.5T-8F1.0A16Q-STFCR/L1103-D180●●1816918032150.50.-7.0.4TC□□1103CSTB-2.5T-8F1.2A20R-STFCR/L1102-D22022201120036180.50.-4.0.4TC□□1102CSTB-2.5T-8F1.0A20R-STFCR/L16-D22022201120036180.40.-7.0.8TC□□16T3CSTB-4MT-15F3.5A25S-STFCR/L16-D270272513.525045230.40.-5.0.8配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径使用刀片标准刀尖圆弧扭矩NewNewNew■硬质合金刀杆.Dmrε(N·m)RL.DsfL1L2hf2θαE08K-STFCR/L09-D1001085.5125227.50.60.-12.0.4TC□□0902CSTB-2.2ST-7F0.7E10M-STFCR/L09-D12012106.51502590.60.-10.0.4E10M-STFCR/L1102-D12012106.51502590.60.-10.0.4TC□□1102CSTB-2.5T-8F1.0E10M-STFCR/L1103-D120●●12106.51502590.70.-13.0.4TC□□1103CSTB-2.5T-8F1.2E12Q-STFCR/L09-D1401412718027110.60.-8.0.4TC□□0902CSTB-2.2T-7F0.7E12Q-STFCR/L1102-D1401412718027110.60.-8.0.4TC□□1102CSTB-2.5T-8F1.0E12Q-STFCR/L1103-D140●●1412718027110.50.-10°0.4TC□□1103CSTB-2.5T-8F1.2E16R-STFCR/L09-D1801816920032150.60.-6.0.4TC□□0902CSTB-2.2T-7F0.7E16R-STFCR/L1102-D1801816920032150.60.-6.0.4TC□□1102CSTB-2.5T-8F1.0E16R-STFCR/L1103-D180●●1816920032150.50.-7°0.4TC□□1103CSTB-2.5T-8F1.2E20S-STFCR/L1102-D22022201125036180.60.-4.0.4TC□□1102CSTB-2.5T-8F1.0E20S-STFCR/L16-D22022201125036180.60.-7.0.8TC□□16T3CSTB-4MT-15F3.5E25T-STFCR/L16-D270272513.530045230.50.-5.0.8NewNew配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径使用刀片标准刀尖圆弧扭矩New(注)当刀片有方向时,右(STFCR□□-)刀体用左(L)刀片,左(STFCR□□-)刀体用右(R)刀片。NewNew:2010年2月推出12●:库存型号STFPR/L车内孔切削S-型(正前角,压孔式).Dmh .Dsf2L1L291°f切削刃形状代号Fθ图示为右手刀杆(R)■钢刀杆刀杆型号库存.Dm最小加工直径尺寸(mm)rε标准刀尖圆弧使用刀片配件(N·m)扭矩RL.DsfL1L2hf2θα紧固螺钉扳手A08H-STFPR/L09-D100●●1085.5100167.50.7+5.-8.0.4TP□□0902CSTB-2.2ST-7F0.9A10K-STFPR/L1102-D120●●12106.51252090.7+5.-6.0.4TP□□1102CSTB-2.5BT-8F1.2A10K-STFPR/L1103-D12012106.51252090.7+5.-7.0.4TP□□1103*CSTB-3L050T-9F1.4A12M-STFPR/L1102-D140●●1412715024110.6+5.-4.0.4TP□□1102CSTB-2.5T-8F1.2A12M-STFPR/L1103-D1401412715024110.6+5.-4.0.4TP□□1103*CSTB-3ST-9F1.4A16Q-STFPR/L1103-D1801816918032150.7+5.-2.0.4A16Q-STFPR/L13-D180●●1816918032150.7+5.-2.0.4TP□□1303CSTB-3ST-9F1.4A20R-STFPR/L13-D220●22201120036180.8+5.-2.0.4CSTB-3A25S-STFPR/L16-D270●272513.525045230.6+5.-1.0.4TP□□16T3CSTB-4MT-15F3.0■硬质合金刀杆刀杆型号库存.Dm最小加工直径尺寸(mm)rε标准刀尖圆弧使用刀片配件(N·m)扭矩RL.DsfL1L2hf2θα紧固螺钉扳手E08K-STFPR/L09-D100●●1085.5125227.50.7+5.-8.0.4TP□□0902CSTB-2.2ST-7F0.9E10M-STFPR/L1102-D120●●12106.51502590.7+5.-6.0.4TP□□1102CSTB-2.5BT-8F1.2E10M-STFPR/L1103-D12012106.51502590.7+5.-7.0.4TP□□1103*CSTB-3L050T-9F1.4E12Q-STFPR/L1102-D140●●1412718027110.6+5.-4.0.4TP□□1102CSTB-2.5T-8F1.2E12Q-STFPR/L1103-D1401412718027110.6+5.-4.0.4TP□□1103*CSTB-3ST-9F1.4E16R-STFPR/L1103-D1801816920032150.7+5.-2.0.4E16R-STFPR/L13-D180●1816920032150.7+5.-2.0.4TP□□1303CSTB-3ST-9F1.4E20S-STFPR/L13-D220●22201125036180.8+5.-2.0.4CSTB-3(注)当刀片有方向时,右(STFPR□□-)刀体用左(L)刀片,左(STFPR□□-)刀体用右(R)刀片。●:库存型号13SJB流线型内径车刀STUPR/L车内孔切削S-型(正前角,压孔式)95°fL2f2L1.Dmhα切削刃形状代号Uθ图示为右手刀杆(R) ■钢刀杆.Ds.Dmrε(N·m)RL.DsfL1L2hf2θαA07G-STUPR/L07-D080●●87490126.750.4+5.-10.0.4TP□□0701CSTB-2.2L038T-7F0.9A08H-STUPR/L07-D080●●88410019.57.50.5+5.-10.0.4TP□□0701CSTB-2.2L038T-7F0.9A08H-STUPR/L09-D100●●1085.5100167.50.6+5.-8.0.4TP□□0902CSTB-2.2L038T-7F0.9A10F-STUPR/L1102-D120●12106.5802091.4+5.-6.0.4TP□□1102CSTB-2.5ST-8F1.2A10K-STUPR/L1102-D120●●12106.51252090.7+5.-6.0.4A10K-STUPR/L1103-D120●●12106.51252090.6+5.-10.0.4TP□□1103*CSTB-3L050T-9F1.4A12H-STUPR/L1102-D140●1412710024110.9+5.-4.0.4TP□□1102CSTB-2.5BT-8F1.2A12M-STUPR/L1102-D140●●1412715024110.7+5.-4.0.4A12M-STUPR/L1103-D140●●1412715024110.6+5.-6.0.4TP□□1103*CSTB-3L050T-9F1.4A12H-STUPR/L1102-D160●1612910024110.6+5.-3.0.4TP□□1102CSTB-2.5BT-8F1.2A12M-STUPR/L1102-D160●●1612915024110.6+5.-3.0.4A16K-STUPR/L13-D180●1816912532150.9+5.-3.0.4TP□□1303CSTB-3ST-9F1.4A16Q-STUPR/L1103-D180●●1816918032150.8+5.-4.0.4TP□□1103*CSTB-3ST-9F1.4A16Q-STUPR/L13-D180●●1816918032150.6+5.-3.0.4TP□□1303CSTB-3ST-9F1.4A16K-STUPR/L13-D200●20161112532150.6+5.-3.0.4TP□□1303CSTB-3ST-9F1.4A16Q-STUPR/L13-D200●●20161118032150.6+5.-3.0.4A20R-STUPR/L1103-D220●●22201120036180.7+5.-2.0.4TP□□1103*A20R-STUPR/L13-D220●●22201120036180.7+5.-2.0.4TP□□1303CSTB-3T-9F1.4A25S-STUPR/L16-D270●●272513.525045230.5+5.-1.0.8TP□□16T3CSTB-4MT-15F3.0A32T-STUPR/L16-D340●●34321730050300.7+5.0.0.8配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径使用刀片标准刀尖圆弧扭矩NewMINI■硬质合金刀杆.Dmrε(N·m)RL.DsfL1L2hf2θαE07H-STUPR/L07-D080●●874100146.750.3+5.-10.0.4TP□□0701CSTB-2.2L038T-7F0.9E08G-STUPR/L07-D080●8849044.57.50.5+5.-10.0.4TP□□0701CSTB-2.2L038T-7F0.9E08K-STUPR/L07-D080●●88412544.57.50.5+5.-10.0.4E08G-STUPR/L09-D100●●1085.5902270.6+5.-8.0.4TP□□0902CSTB-2.2L038T-7F0.9E08K-STUPR/L09-D100●1085.51252270.6+5.-8.0.4E10F-STUPR/L1102-D120●12106.5802590.5+5.-6°0.4TP□□1102CSTB-2.5ST-8F1.2E10H-STUPR/L1102-D120●12106.51002590.6+5.-6.0.4E10M-STUPR/L1102-D120●●12106.51502590.6+5.-6.0.4E10M-STUPR/L1103-D120●●12106.51502590.7+5.-10.0.4TP□□1103*CSTB-3L050T-9F1.4E12G-STUPR/L1102-D140●141279027110.9+5.-4.0.4TP□□1102CSTB-2.5ST-8F1.2E12J-STUPR/L1102-D140●1412711027110.6+5.-4.0.4CSTB-2.5BT-8F1.2E12Q-STUPR/L1102-D140●●1412718027110.6+5.-4.0.4E12Q-STUPR/L1103-D140●●1412718027110.7+5.-6.0.4TP□□1103*CSTB-3L050T-9F1.4E12G-STUPR/L1102-D160●161299027110.6+5.-3.0.4TP□□1102CSTB-2.5BT-8F1.2E12J-STUPR/L1102-D160●1612911027110.6+5.-3.0.4E12Q-STUPR/L1102-D160●●1612918027110.6+5.-3.0.4E16H-STUPR/L13-D180●1816910032150.9+5.-3.0.4TP□□1303CSTB-3ST-9F1.4E16R-STUPR/L1103-D180●●1816920032150.8+5.-4.0.4TP□□1103*CSTB-3ST-9F1.4E16L-STUPR/L13-D180●1816913032150.6+5.-3.0.4TP□□1303CSTB-3ST-9F1.4E16R-STUPR/L13-D180●●1816920032150.6+5.-3.0.4E16H-STUPR/L13-D200●20161110032150.6+5.-3.0.4E16L-STUPR/L13-D200●20161113032150.6+5.-3.0.4E16R-STUPR/L13-D200●●20161120032150.6+5.-3.0.4E20S-STUPR/L1103-D220●22201125036180.7+5.-2.0.4TP□□1103*CSTB-3ST-9F1.4E20S-STUPR/L13-D220●22201125036180.6+5.-2.0.4TP□□1303CSTB-3T-9F1.4E25T-STUPR/L16-D270●272513.530045230.5+5.-1.0.8TP□□16T3CSTB-4MT-15F3.0配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径使用刀片标准刀尖圆弧扭矩NewMINI14(注)当刀片有方向时,右(STUPR□□-)刀体用左(L)刀片,左(STUPR□□-)刀体用右(R)刀片。●:库存型号SVQBR/L车内孔&仿形切削S-型(正前角,压孔式).Dmh25.5° 117.5°ff2L1L2.Dsα切削刃形状代号Q图示为右手刀杆(R)■钢刀杆刀杆型号库存.Dm最小加工直径尺寸(mm)rε标准刀尖圆弧使用刀片配件(N·m)扭矩RL.DsfL1L2hf2θα紧固螺钉扳手A12M-SVQBR/L11-D170●●171210.515024114.5-5.-10.0.4VB□□1103CSTB-2.5T-8F1.2A16Q-SVQBR/L11-D215●●21.5161318030155-5.-8.0.4A20R-SVQBR/L11-D255●●25.5201520036185-5.-6.0.4A25S-SVQBR/L16-D305●●30.52517.525045235-5.-8.0.8VB□□1604CSTB-3.5T-15F3.0■硬质合金刀杆刀杆型号库存.Dm最小加工直径尺寸(mm)rε标准刀尖圆弧使用刀片配件(N·m)扭矩RL.DsfL1L2hf2θα紧固螺钉扳手E12Q-SVQBR/L11-D170●●171210.518027114.5-5.-10.0.4VB□□1103CSTB-2.5T-8F1.2E16R-SVQBR/L11-D215●●21.5161320032155-5.-8.0.4E20S-SVQBR/L11-D255●●25.5201525036185-5.-6.0.4E25T-SVQBR/L16-D305●●30.52517.530045235-5.-8.0.8VB□□1604CSTB-3.5T-15F3.0(注)当刀片有方向时,右(SVQBR□□-)刀体用左(L)刀片,左(SVQBR□□-)刀体用右(R)刀片。SVQCR/LS-型(正前角,压孔式)车内孔&仿形切削.Dmh25.5° 117.5°ff2L1L2.Dsα切削刃形状代号Q图示为右手刀杆(R)■钢刀杆.Dmrε(N·m)RL.DsfL1L2hf2θαA10K-SVQCR/L08-D135●●13.51081252093-5.-8.0.4VC□□0802CSTB-2LT-6F0.6A16Q-SVQCR/L11-D215●●21.5161318030154.9-5.-8.0.4VC□□1103CSTB-2.5T-8F1.2A25S-SVQCR/L16-D32032251725045234.50.-5.0.8VC□□1604CSTB-3.5T-15F3.0A32T-SVQCR/L16-D400403222300502360.-3.0.8A40U-SVQCR/L16-D500504027350602370.-1.0.8配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径使用刀片标准刀尖圆弧扭矩New■硬质合金刀杆.Dmrε(N·m)RL.DsfL1L2hf2θαE10M-SVQCR/L08-D135●●13.51081502593-5.-8.0.4VC□□0802CSTB-2LT-6F0.6E16R-SVQCR/L11-D215●●21.5161320032154.9-5.-8.0.4VC□□1103CSTB-2.5T-8F1.2配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径使用刀片标准刀尖圆弧扭矩New(注)当刀片有方向时,右(SVQCR□□-)刀体用左(L)刀片,左(SVQCR□□-)刀体用右(R)刀片。:2010年2月推出New●:库存型号15SJB流线型内径车刀16SVZBR/LSVUCR/LSVUBR/L .Dmh.Dsf2L1L293°fL350° .Dm 93°93°ffL2f2f2L1L1.Ds.Dsh50° .Dm 93°93°ffL2f2f2L1L1.Ds.Dsh50°RL.Dm.DsfL1L2hf2θαrε(N·m)A16Q-SVUBR/L11-D200●●201615.5180351580.-8.0.4VB□□1103CSTB-2.5T-8F1.2A20R-SVUBR/L11-D250●●252017.5200401980.-7.0.4A25S-SVUBR/L16-D320●●322520.525050238.50.-6.0.8VB□□1604CSTB-3.5T-15F3.0RL.Dm.DsfL1L2hf2θαrε(N·m)E16R-SVUBR/L11-D245●●24.51616200-1580.-8.0.4VB□□1103CSTB-2.5T-8F1.2E20S-SVUBR/L11-D285●●28.52018250-1980.-7.0.4E25T-SVUBR/L16-D340●●342521300-238.50.-6.0.8VB□□1604CSTB-3.5T-15F3.0RL.Dm.DsfL1L2hf2θαrε(N·m)A12M-SVUCR/L08-D160●●16121115030115.50.-8.0.4VC□□0802CSTB-2LT-6F0.6A25S-SVUCR/L16-D320●●32251925045236.50.-5.0.8VC□□1604CSTB-3.5A32T-SVUCR/L16-D400403222300503060.-3.0.8T-15F3.0CSTB-3.5LA40U-SVUCR/L16-D500504027350603770.-1.0.8RL.Dm.DsfL1L2hf2θαrε(N·m)E12Q-SVUCR/L08-D180●●181211.5180-115.50.-8.0.4VC□□0802CSTB-2LT-6F0.6E25T-SVUCR/L16-D320●●322519300-236.50.-5.0.8VC□□1604CSTB-3.5T-15F3.0RL.Dm.DsfL1L2L3hf2θαrε(N·m)A16Q-SVZBR/L11-D200●●201615.51803512.51580.-8.0.4VB□□1103CSTB-2.5T-8F1.2A20R-SVZBR/L11-D250●●252017.52004012.51880.-7.0.4A25S-SVZBR/L16-D320●●3225242505017.523120.-6.0.8VB□□1604CSTB-3.5T-15F3.0A32T-SVZBR/L16-D400●●403227.53007217.530120.-5.0.8CSTB-3.5L车内孔&仿形切削切削刃形状代号US-型(正前角,压孔式)车内孔&仿形切削切削刃形状代号US-型(正前角,压孔式)图示为右手刀杆(R)■钢刀杆■硬质合金刀杆(注)当刀片有方向时,右(SVUBR□□-)刀体用左(L)刀片,左(SVUBR□□-)刀体用右(R)刀片。(注)当刀片有方向时,右(SVZBR□□-)刀体用左(L)刀片,左(SVZBR□□-)刀体用右(R)刀片。硬质合金刀杆形状切削刃形状代号Z图示为右手刀杆(R)图示为右手刀杆(R)S-型(正前角,压孔式)■钢刀杆■硬质合金刀杆■钢刀杆(注)当刀片有方向时,右(SVUCR□□-)刀体用左(L)刀片,左(SVUCR□□-)刀体用右(R)刀片。●:库存型号车内孔&仿形加工硬质合金刀杆形状配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径使用刀片标准刀尖圆弧扭矩配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径使用刀片标准刀尖圆弧扭矩配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径使用刀片标准刀尖圆弧扭矩配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径使用刀片标准刀尖圆弧扭矩配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径使用刀片标准刀尖圆弧扭矩SVZCR/L车内孔&仿形加工S-型(正前角,压孔式).Dmh L2.Dsf2L193°fL350°切削刃形状代号Zθ图示为右手刀杆(R)■钢刀杆刀杆型号库存.Dm最小加工直径尺寸(mm)rε标准刀尖圆弧使用刀片配件(N·m)扭矩RL.DsfL1L2L3hf2θα紧固螺钉扳手A12M-SVZCR/L08-D160●●1612111503010115.50.-8.0.4VC□□0802CSTB-2LT-6F0.6(注)当刀片有方向时,右(SVZCR□□-)刀体用左(L)刀片,左(SVZCR□□-)刀体用右(R)刀片。SWUBR/L车内孔切削S-型(正前角,压孔式)θ*直柄刀杆形式h 93°fL.Ds1切削刃形状代号U■钢刀杆图示为右手刀杆(R).Dm93°.DsfL2L1.Dmrε(N·m)RL.DsfL1L2hf2θα*A05F-SWUBR/L03-D060●●6538094.8-0.-13.0.4WB□□0301CSTB-2T-6F0.6*A06G-SWUBR/L03-D070●●763.590115.75-12.*A07G-SWUBR/L03-D080●●87490126.75-11.A08H-SWUBR03-D060●683.1100187.5-0.-12.0.4WB□□0301CSTB-2T-6F0.6A08H-SWUBR03-D070●783.6100207.5-0.-12.0.4配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径使用刀片标准刀尖圆弧扭矩NewMININewMININewMINI■硬质合金刀杆.Dmrε(N·m)RL.DsfL1L2hf2θα*E05G-SWUBR/L03-D060●●65390104.8-0.-13.0.4WB□□0301CSTB-2T-6F0.6*E06H-SWUBR/L03-D070●●763.5100125.75-12.*E07H-SWUBR/L03-D080●●874100146.75-11.E08K-SWUBR03-D060●683.1125307.5-0.-12.0.4WB□□0301CSTB-2T-6F0.6E08K-SWUBR03-D070●783.6125407.5-0.-12.0.4配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径使用刀片标准刀尖圆弧扭矩NewMININewMININewMINI(注)当刀片有方向时,右(SWUBR□□-)刀体用左(L)刀片,左(SWUBR□□-)刀体用右(R)刀片。SEZPR/L车内孔&仿形加工S-型(正前角,压孔式)95°fL2f2L1.Ds.Dmh 切削刃形状代号Zθ■钢刀杆图示为右手刀杆(R).Dmrε(N·m)RL.DsfL1L2hf2θαA04F-SEZPR/L03-D055●●5.543.28043.81.20.-8.0.2EP□□03X1CSTA-1.6T-6F0.6A05F-SEZPR/L03-D065●●6.553.78054.8-6.配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径使用刀片标准刀尖圆弧扭矩NewMININewMINI■硬质合金刀杆.Dmrε(N·m)RL.DsfL1L2hf2θαE04G-SEZPR/L03-D055●●5.543.29053.81.20.-8.0.2EP□□03X1CSTA-1.6T-6F0.6E05G-SEZPR/L03-D065●●6.553.79064.8-6.配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径使用刀片标准刀尖圆弧扭矩NewMININewMINI(注)当刀片有方向时,右(SEZPR□□-)刀体用左(L)刀片,左(SEZPR□□-)刀体用右(R)刀片。●:库存型号17SJB流线型内径车刀SVJBR/L车内孔球面加工S-型(正前角,压孔式).Dm142°hfL2L1.Dsαθ切削刃形状代号J图示为右手刀杆(R)■钢刀杆刀杆型号库存.Dm最小加工直径尺寸(mm)rε标准刀尖圆弧适用刀片配件(N·m)扭矩RL.DsfL1L2hf2θα紧固螺钉扳手A20R-SVJBR/L11-D250●●252022004018--5.-5.0.4VB□□1103CSTB-2.5T-8F1.2A25S-SVJBR/L11-D300●●30253.52505023--5.-5.0.4(注)当刀片有方向时,右(SVJBR□□-)刀体用左(L)刀片,左(SVJBR□□-)刀体用右(R)刀片。SVJCR/L车内孔球面加工S-型(正前角,压孔式).Dm142°h图示为右手刀杆(R)αθ切削刃形状代号JfL1L2.Ds■钢刀杆刀杆型号库存.Dm最小加工直径尺寸(mm)rε标准刀尖圆弧适用刀片配件(N·m)扭矩RL.DsfL1L2hf2θα紧固螺钉扳手A12M-SVJCR/L08-D160●●161221502811--5.-5.0.4VC□□0802CSTB-2LT-6F0.6A16Q-SVJCR/L08-D200●●201621803515--5.-5.0.4(注)当刀片有方向时,右(SVJLCR□□-)刀体用左(L)刀片,左(SVJCR□□-)刀体用右(R)刀片。SEXPR/L车内孔&端面切削S-型(正前角,压孔式).Dmh 100°fL1.DsL2100°fL1.Ds*直柄刀杆形式α切削刃形状代号X■钢刀杆图示为右手刀杆(R).Dmrε(N·m)RL.DsfL1L2hf2θα*A04F-SEXPR/L03-D045●●4.542.38083.8-0.-15.0.2EP□□03X1CSTA-1.6T-6F0.6*A04F-SEXPR/L03-D050●●542.58083.8-0.-13.0.2*A05F-SEXPR/L04-D055●●5.552.758094.8-0.-12.0.4EP□□0401CSTB-2T-6F0.6*A06G-SEXPR/L04-D070●●763.690115.75-0.-12.0.4EP□□0401CSTB-2T-6F0.6A08H-SEXPR/L04-D055●●5.582.75100167.5-0.-12.0.4EP□□0401CSTB-2T-6F0.6A08H-SEXPR/L04-D070●●783.6100207.5-0.-12.0.40.6配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径适用刀片标准刀尖圆弧扭矩NewMININewMININewMININewMINI■硬质合金刀杆.Dmrε(N·m)RL.DsfL1L2hf2θα*E04G-SEXPR/L03-D045●●4.542.39093.8-0.-15.0.2EP□□03X1CSTA-1.6T-6F0.6*E04G-SEXPR/L03-D050●●542.59093.8-0.-13.0.2*E05G-SEXPR/L04-D055●●5.552.7590104.8-0.-12.0.4EP□□0401CSTB-2T-6F0.6*E06H-SEXPR/L04-D070●●763.6100125.75-0.-12.0.4EP□□0401CSTB-2T-6F0.6E08K-SEXPR/L04-D055●●5.582.75125287.5-0.-12.0.4EP□□0401CSTB-2T-6F0.6E08K-SEXPR/L04-D070●●783.6125407.5-0.-12.0.40.6配件紧固螺钉扳手库存最小尺寸(mm)刀杆型号加工直径适用刀片标准刀尖圆弧扭矩NewMININewMININewMININewMINI18(注)当刀片有方向时,右(SEXPR□□-)刀体用左(L)刀片,左(SEXPR□□-)刀体用右(R)刀片。●:库存型号SVJC(B)R/L型刀具的使用方法加工范围能够加工的内孔球面最小半径(R)如右图所示,为最小镗孔直径(.Dm)的1/2。最大加工深度可达到L2。L2L2R(D/2).Dm注意事项加工时刀尖不能超过中心,否则会导致刀片崩刃。加工实例内球面加工被加工材料:S45C刀杆:A12M-SVJCR08-D160刀片:VCMT080204-PF(NS730)切削速度:Vc=~100m/min转速:n=3000min-1(连续稳定的)进给:f=0.1mm/rev切深:ap=0.5mm请将切深设在刀尖半径R以下,否则会产生毛刺。ap刀尖半径R以下内端面加工被加工材料刀杆刀片切削速度转速进给切深:S45C:A12M-SVJCR08-D160:VCMT080204-PF(T9015):Vc=~100m/min:n=3000min-1(连续稳定的):f=0.1mm/rev:f=0.05mm/rev(仅在切断时):ap=0.5mm16mmR820mm.16apap从实心工件表面开始加工从有预钻孔底面开始加工从实心工件表面开始加工从有预钻孔底面开始加工19SJB流线型内径车刀30°.Dm■钢刀杆切削刃形状代号Q图示为右手刀杆(R)122.5°L2L1h.Dsf f2SYQBR/LS-型(正前角,压孔式)车内孔&仿形切削刀杆型号库存.Dm最小加工直径尺寸(mm)rε标准刀尖圆弧适用刀片配件(N·m)扭矩RL.DsfL1L2hf2θα紧固螺钉扳手A12M-SYQBR/L11-D170●●171210.515024114.5-5.-10.0.4YW□□11T2CSTB-2LT-6F0.6A16Q-SYQBR/L11-D215●●21.5161318030155-5.-8.0.4■硬质合金刀杆刀杆型号库存.Dm最小加工直径尺寸(mm)rε标准刀尖圆弧适用刀片配件(N·m)扭矩RL.DsfL1L2hf2θα紧固螺钉扳手E12Q-SYQBR/L11-D170●●171210.518027114.5-5.-10.0.4YW□□11T2CSTB-2LT-6F0.6E16R-SYQBR/L11-D215●●21.5161320032155-5.-8.0.4SYUBR/LS-型(正前角,压孔式)车内孔&仿形切削.DmL2h ff2L1.Ds93°60°切削刃形状代号U■钢刀杆图示为右手刀杆(R)刀杆型号库存.Dm最小加工直径尺寸(mm)rε标准刀尖圆弧适用刀片配件(N·m)扭矩RL.DsfL1L2hf2θα紧固螺钉扳手A16Q-SYUBR/L11-D200●●201615.5180351580.-8.0.4YW□□11T2CSTB-2LT-6F0.6■硬质合金刀杆刀杆型号库存.Dm最小加工直径尺寸(mm)rε标准刀尖圆弧适用刀片配件(N·m)扭矩RL.DsfL1L2hf2θα紧固螺钉扳手E12Q-SYUBR/L11-D200●●201213.518027117.50.-8.0.4YW□□11T2CSTB-2LT-6F0.6E16R-SYUBR/L11-D245●●24.51616200321580.-8.0.420●:库存型号PCLNR/L车内孔&端面切削P-型(负前角,侧推式)PCLNR/L车内孔&端面切削P-型(负前角,侧推式).Dmh95°fL2f2L1.Dsr αθ切削刃形状代号L图示为右手刀杆(R)■钢刀杆刀杆型号库存.Dm最小加工直径.DsfL1尺L2寸h(mm)f2θαrε标准刀尖圆弧适用刀片刀垫侧推坚固螺钉配件弹簧扳手油冷附件油孔螺钉(N·m)扭矩RLA16M-PCLNR/L09-D200●●20161115032153-6.-14.0.8-SSHM3-41.7A20Q-PCLNR/L09-D250●●25201318036183-6.-12.0.8CN□□0903-LCL32NLCS22A-P-2FEA-20A25R-PCLNR/L09-D320●●32251720045234.5-6.-11.0.8EA-25SSHM5-6A25R-PCLNR/L12-D320●●32251720045234.5-6.-13.0.8-LCL43NLCS43-P-2.5EA-25SSHM5-62.7A32S-PCLNR/L12-D400●●40322225050306-6.-11.0.8CN□□1204EA-324.8A40T-PCLNR/L12-D500●●50402730060377-6.-10.0.8LSC42BR/LLCL4LCS4LSP4P-3-SSHM6-6A50U-PCLNR/L12-D630●●635035350654710-6.-8.0.8(注)当刀片有方向时,右(PCLNR□□-)刀体用左(L)刀片,左(PCLNR□□-)刀体用右(R)刀片。PDUNR/L车内孔&仿形切削P-型(负前角,侧推式).Dmh93°L2f2fL1.Dsr αθ切削刃形状代号U图示为右手刀杆(R)■钢刀杆刀杆型号库存.Dm最小加工直径.DsfL1尺L2寸h(mm)f2θαrε标准刀尖圆弧适用刀片刀垫侧推坚固螺钉配件弹簧扳手油冷附件油孔螺钉(N·m)扭矩RLA20Q-PDUNR/L11-D250●●25201318036183-6.-14.0.8DN□□1104-LCL33NLLCS22A-P-2FEA-20SSHM2.5-31.7A25R-PDUNR/L11-D320●●32251720045234.5-6.-12.0.8ELSD317BR/LLCL33LLCS3LSP3P-2.5EA-25SSHM3-42.7A32S-PDUNR/L15-D400●●40322225050306-6.-13.0.8EA-32SSHM5-64.8A40T-PDUNR/L15-D500●●50402730060377-6.-10.0.8DN□□1504LSD42BR/LLCL4LCS4LSP4P-3-SSHM6-6A50U-PDUNR/L15-D630●●635035350654710-6.-8.0.8A32S-PDUNR/L1506-D400●●40322225050306-6.-13.0.8EA-32SSHM5-64.8A40T-PDUNR/L1506-D500●●50402730060377-6.-11.0.8DN□□1506ELSD42LCL44ELCS4LSP4SP-3-SSHM6-6A50U-PDUNR/L1506-D630●●635035350654710-6.-10.0.8(注)当刀片有方向时,右(PDUNR□□-)刀体用左(L)刀片,左(PDUNR□□-)刀体用右(R)刀片。PDZNR/L反车内孔切削P-型(负前角,侧推式)α 图示为右手刀杆(R)■钢刀杆.Dmh93°fL2f2L1.Dsr 切削刃形状代号Z刀杆型号库存.Dm最小加工直径.DsfL1L2尺寸h(mmf2)θαrε标准刀尖圆弧适用刀片刀垫侧推坚固螺钉配件弹簧扳手油冷附件油孔螺钉(N·m)扭矩RLA32S-PDZNR/L15-D400●●403222250503011.5-6.-13.0.8EA-32SSHM4-54.8A40T-PDZNR/L15-D500●●504027300603714.5-6.-10.0.8DN□□1504LSZ42BR/LLCL4LCS4LSP4P-3-SSHM5-6A50U-PDZNR/L15-D630●●635035350654714.5-6.-8.0.8SSHM6-6(注)当刀片有方向时,右(PDZNR□□-)刀体用左(L)刀片,左(PDZNR□□-)刀体用右(R)刀片。●:库存型号21SJB流线型内径车刀PSKNR/L车内孔切削P-型(负前角,侧推式).Dmhα75°fL2f2L1.Dsr θ图示为右手刀杆(R)■钢刀杆切削刃形状代号K刀杆型号库存.Dm最小加工直径.DsfL1尺L2寸h(mm)f2θαrε标准刀尖圆弧适用刀片刀垫侧推坚固螺钉配件弹簧扳手油冷附件油孔螺钉(N·m)扭矩RLA32S-PSKNR/L12-D400●●40322225050306-6.-10.0.8EA-32SSHM4-54.8A40T-PSKNR/L12-D500●●50402730060377-6.-10.0.8SN□□1204LSS42BR/LLCL4LCS4LSP4P-3-SSHM6-6A50U-PSKNR/L12-D630●●635035350654710-6.-8.0.8(注)当刀片有方向时,右(PSKNR□□-)刀体用左(L)刀片,左(PSKNR□□-)刀体用右(R)刀片。PTFNR/L车内孔&切削P-型(负前角,侧推式).Dmr f2L1L291°fhθ图示为右手刀杆(R)■钢刀杆.Ds切削刃形状代号F刀杆型号库存.Dm最小加工直径.DsfL1尺L2寸h(mm)f2θαrε标准刀尖圆弧适用刀片刀垫侧推坚固螺钉配件弹簧扳手油冷附件油孔螺钉(N·m)扭矩RLA25R-PTFNR/L16-D320●●32251720045231.2-6.-12.0.8ELST317BR/LLCL33EA-25SSHM4-52.7A32S-PTFNR/L16-D400●●40322225050301.1-6.-10.0.8TN□□1604LCS3LSP3P-2.5EA-32A40T-PTFNR/L16-D500●●50402730060371.1-6.-10.0.8LST317BR/LLCL3-SSHM6-6A50U-PTFNR/L16-D630●●63503535065471.1-6.-8.0.8(注)当刀片有方向时,右(PTFNR□□-)刀体用左(L)刀片,左(PTFNR□□-)刀体用右(R)刀片。PTUNR/L车内孔&切削P-型(负前角,侧推式)切削刃形状代号Ur .Dsf2L1L295°f.Dmh图示为右手刀杆(R)■钢刀杆刀杆型号库存.Dm最小加工直径.DsfL1尺L2寸h(mm)f2θαrε标准刀尖圆弧适用刀片刀垫侧推坚固螺钉配件弹簧扳手油冷附件油孔螺钉(N·m)扭矩RLA16M-PTUNR/L11-D200●●20161115032151-6.-14.0.4TN□□1103-LCL22NLCS22A-P-2F-SSHM3-41.7A20Q-PTUNR/L11-D250●●25201318036181-6.-12.0.4EA-20A25R-PTUNR/L16-D320●●32251720045231.4-6.-12.0.8TN□□1604ELST317BR/LLCL33LCS3LSP3P-2.5EA-25SSHM4-52.7A32S-PTUNR/L16-D400●●40322225050301.3-6.-10.0.8LST317BR/LLCL3EA-3222*刀片压紧要它遵循国际标准。*刀杆长度可能和国际标准不同。(注)当刀片有方向时,右(PTUNR□□-)刀体用左(L)刀片,左(PTUNR□□-)刀体用右(R)刀片。●:库存型号PVUNR/L车内孔&仿形切削P-型(负前角,侧推式)PVUNR/L车内孔&仿形切削P-型(负前角,侧推式).Dmh93°fL2f2L1.Dsr α 图示为右手刀杆(R)■钢刀杆50°切削刃形状代号U刀杆型号库存.Dm最小加工直径.DsfL1尺L2寸h(mm)f2θαrε标准刀尖圆弧适用刀片刀垫侧推坚固螺钉配件弹簧扳手油冷附件油孔螺钉(N·m)扭矩RLA25R-PVUNR/L16-D370●●37252220045239.5-5.-14.0.8EA-25SSHM3-42.7A32S-PVUNR/L16-D400●●40322225050306-5.-12.0.8VN□□1604LSV317BR/LLCL3VLCS3VLSP3P-2.5EA-32A40T-PVUNR/L16-D500●●50402730060377-5.-10.0.8-SSHM5-6PWLNR/L车内孔&端面切削P-型(负前角,侧推式).Dmhα切削刃形状代号Lθ95°fL2f2L1.Dsr 图示为右手刀杆(R)■钢刀杆刀杆型号库存.Dm最小加工直径.DsfL1尺L2寸h(mm)f2θαrε标准刀尖圆弧适用刀片刀垫侧推坚固螺钉配件弹簧扳手油冷附件油孔螺钉(N·m)扭矩RLA16M-PWLNR/L06-D200●●20161115032153-8.-17.0.8-LCL33NLCS33-P-2F-SSHM3-41.7A20Q-PWLNR/L06-D250●●25201318036183-6.-14.0.8WN□□0604--EA-20A25R-PWLNR/L06-D320●●32251720045234.5-6.-12.0.8LCL3LCS3BLSP3P-2.5EA-25SSHM5-62.7A32S-PWLNR/L06-D400●●40322225050306-6.-11.0.8LSW312BR/LLCS3P-2.5EA-32A25R-PWLNR/L08-D320●●32251720045234.5-6.-13.0.8-LCL43NLCS43-P-2.5EA-25SSHM5-62.7A32S-PWLNR/L08-D400●●40322225050306-6.-11.0.8WN□□0804LCL4LCS4LSP4P-3EA-324.8A40T-PWLNR/L08-D500●●50402730060377-6.-10.0.8LSW42BR/L-SSHM6-6●:库存型号23SJB流线型内径车刀小直径加工用刀片80°菱形,7°后角有孔.ds.d1rεSH730TH10W08CCGT03X100R-W083.571.391.90.03●●CCGT03X100L-W08●●CCGT03X101R-W080.10●●CCGT03X101L-W08●●CCGT03X102R-W080.20●●CCGT03X102L-W08●●CCGT03X104R-W080.40●●CCGT03X104L-W08●●CCGT04T100R-W084.371.792.30.03●●CCGT04T100L-W08●●CCGT04T101R-W080.10●●CCGT04T101L-W08●●CCGT04T102R-W080.20●●CCGT04T102L-W08●●CCGT04T104R-W080.40●●CCGT04T104L-W08●●15oNew适用范围精加工断屑槽刀片型号形状(剖面)刀片型号(公制)内切圆直径厚度孔径(.)刀尖圆弧尺寸(mm)材质涂层硬质合金75°菱形,11°后角有孔.ds.d1rεW08EPGT03X100R-W083.571.391.90.03●●EPGT03X100L-W08●●EPGT03X101R-W080.10●●EPGT03X101L-W08●●EPGT03X102R-W080.20●●EPGT03X102L-W08●●EPGT03X104R-W080.40●●EPGT03X104L-W08●●EPGT040100R-W083.971.592.30.03●●EPGT040100L-W08●●●●EPGT040101R-W080.10●●EPGT040101L-W08●●EPGT040102R-W080.20●●●●EPGT040102L-W08●●●●●●EPGT040104R-W080.40●●●●EPGT040104L-W08●●●●●●J08EPGT040100L-J083.971.592.30.03●●EPGT040102L-J080.20●●EPGT040104L-J080.40●●15o15oNewSH730J740GH110NS530GT530TH10UX30适用范围精加工小型车库专用材质涂层硬质合金金属陶瓷断屑槽刀片型号形状(剖面)刀片型号(公制)内切圆直径厚度孔径(.)刀尖圆弧尺寸(mm)24●:库存型号80°六边形,5°后角有孔.ds.d1rεSH730TH10W08TPGT070100R-W084.371.592.580.03●●TPGT070100L-W08●●TPGT070101R-W080.10●●TPGT070101L-W08●●TPGT070102R-W080.20●●TPGT070102L-W08●●TPGT070104R-W080.40●●TPGT070104L-W08●●.ds.d1rεW08WBGT030100R-W083.971.592.30.03●WBGT030100L-W08●●●●WBGT030101R-W080.01●WBGT030101L-W08●●WBGT030102R-W080.02●WBGT030102L-W08●●●●●WBGT030104R-W080.04●WBGT030104L-W08●●●●●15o15oNewNewSH730GH110NS530TH10UX30断屑槽刀片型号形状(剖面)刀片型号(公制)内切圆直径厚度孔径(.)刀尖圆弧尺寸(mm)材质涂层硬质合金适用范围精加工适用范围精加工材质涂层硬质合金金属陶瓷断屑槽刀片型号形状(剖面)刀片型号(公制)内切圆直径厚度孔径(.)刀尖圆弧尺寸(mm)60°正三角形,11°后角有孔标准切削参数被加工材质断屑槽材质Vc(m/min)切削速度ap(mm)切深进给率f(mm/rev)R0.03R0.1R0.2R0.4钢S45C,SCM435等W08J08SH73050-100-1500.05-0.5-1.00.005~0.01~0.020.01~0.03~0.050.02~0.06~0.100.05~0.10~0.15不锈钢SUS303,SUS304等30-100-150灰铁球铁FC250,FCD450等W08TH1030-70-100铝合金铜合金Si<13%100-300-500Ti合金Ti-6Al-4V等SH73030-60-100●:库存型号25SJB流线型内径车刀导套BLM型(圆柄,迷你流线型镗刀杆专用)hNew10L1b.Dn.Di.DOS1ABCS2S3型号库存尺寸(mm)安装配件.Do.Di.DnL1bS1S2S3紧固螺钉扳手密封帽*(螺纹规格)hABCBLM159-04●4151001551515SSHM4-4SSHM4-4SSHM4-4P-2CA-16(M6)BLM159-05●15.8755BLM159-06●615.8752020BLM159-07●7BLM16-04●415100151651515SSHM4-4SSHM4-4SSHM4-4P-2CA-16(M6)BLM16-05●165BLM16-06●62020BLM16-07●7BLM19-04●41515SSHM4-6SSHM4-6P-2CA-16(M6)BLM19-05●19.055181001819.055SSHM4-4SSHM4-4SSHM4-4BLM19-06●62020BLM19-07●7BLM20-04●4131515SSHM4-6SSHM4-6P-2CA-16(M6)BLM20-05●20514BLM20-06●615100192052020SSHM4-4SSHM4-4SSHM4-4BLM20-07●716BLM22-04●413125212251515SSHM4-4SSHM4-6SSHM4-6P-2CA-16(M6)BLM22-05●22514BLM22-06●6152020BLM22-07●716BLM25-04●413125242551515SSHM4-4SSHM4-8SSHM4-8P-2CA-16(M6)BLM25-05●25514BLM25-06●6152020BLM25-07●716SSHM4-6SSHM4-6BLM254-04●4131252425.451515SSHM4-4SSHM4-8SSHM4-8P-2CA-16(M6)BLM254-05●25.4514BLM254-06●6152020BLM254-07●716SSHM4-6SSHM4-6*密封帽(可选):2010年2月推出26●:库存型号..1..2.D.d..bh2516.D.14(10)4-M6(3-M6)4525h.D..40503010R3/8b163-M6..b.d.D3-M5X0.8h..1..2.d.DBLC型(短型)BLS型(方刀杆)BLS-C型(方刀杆)BLM型(圆刀杆)BLC型(标准型)上图所示为BLM25-**C型.()适用于BLS16-08削平型号库存.D适用刀杆直径尺寸(mm)RhbBLS16-08●81252812.5BLS16-10●10BLS16-12●12型号库存.D适用刀杆直径尺寸(mm)RhbBLS16-08C●81002812.5BLS16-10C●10BLS16-12C●12型号库存.D适用刀杆直径尺寸(mm).dRhbBLM19-08●19.051001818BLM20-08●2019BLM22-08●8221252121BLM254-08●25.424BLM25-08C●25552423BLM25-10C●10BLM25-12C●12型号库存.D适用刀杆直径尺寸(mm)R1R2.dBLC40-8●8731340BLC40-10●10BLC40-12●12BLC40-16●16型号库存.D适用刀杆直径尺寸(mm)R1R2.dBLC32-8C●8452032BLC32-10C●10BLC32-12C●12BLC40-8C●8551340BLC40-10C●10BLC40-12C●12BLC40-16C●16●:库存型号27SJB流线型内径车刀加工实例刀杆:A16Q-STUPR1103-D180刀片:TPMT110308-PS(T6030)40mm被加工材质:SUS304切削速度:Vc=120m/min切深:ap=0.1~3.0mm进给:f=0.15mm/rev切削液:水溶性(外冷)结果提高了刀具寿命和加工稳定性流线型刀杆150pcs.竞争对手加工零件数50~100pcs.竞争对手的刀具经常由于排屑不良引起刀片破损和刀片寿命不稳定,而流线型刀杆由于良好的容屑槽设计,所以在切屑控制上表现优异。消除了由于排屑不良引起的不可预期的刀片破损,提供了稳定的刀具寿命。流线型刀杆加工锥孔时,消除了铁屑缠绕并且提供了优异的断屑表现。.22.38刀杆:A12M-SDUCR07-D16040mm刀片:DCMT070204-PS(GT730)被加工材质:S45C.28.17.608mm提高50%的寿命流线型刀杆300pcs.竞争对手加工零件数200pcs.切削速度:Vc=170m/min切深:ap=0.25mm进给:f=0.15mm/rev切削液:水溶性(内冷)结果和原来使用的竞争对手相比,提高了50%的寿命,表面粗糙度也得了到改善,并且在加工小直径(Φ17)部分时,断屑效果得到了改善。刀杆:A16Q-SDUCR07-D200刀片:DCMT070208-PS(GH730)30mm被加工材质:SCr420H提高了刀具寿命和加工稳定性流线型刀杆40pcs.竞争对手加工零件数断裂稳定20~40pcs.切削速度:Vc=70m/min切深:ap=0.2mm进给:f=0.18mm/rev切削液:水溶性(内冷)结果.60.30.36.50.40.21竞争对手经常出现不良的断屑效果,并且刀具寿命不稳定,流线型刀杆能阻止不良断屑的发生并且能提供稳定的刀具长寿命。20mm刀杆:A16Q-SCLPR09-D180刀片:CPMT090308-PS(NS730)被加工材质:SCM42HV流线型刀杆600pcs./H竞争对手生产效率500pcs./H提高20%的生产效率切削速度:Vc=185m/min切深:ap=0.4mm进给:f=0.15mm/rev切削液:水溶性(内冷)结果竞争对手的刀具常常使切屑缠绕到刀杆上,导致加工时不得不停机以清理切屑,这大大降低了生产效率。流线型刀杆加式时不缠屑所以不用停机,生产效率大大提高了20%(从每小时加工500件提高到600件)。28刀杆:A12M-STUPR1103-D140刀片:TPMT110304-PM(GH730)38mm被加工材质:S20C切削速度:Vc=220m/min切深:ap=0.5mm进给:f=0.2mm/rev切削液:水溶性(外冷)结果Vc=220m/minVc=180m/min流线型刀杆提高了切削速度(生产效率增加了20%)竞争对手切削速度为了防止振刀,以前加工速度不能高于180m/min,使用流线型刀杆后,即使速度提高到220m/min也不会振刀,在加工同样数量工件后的表面粗糙度更好,尺寸精度也得到了改善。.60.32.35.32.4230°.25.25.17刀杆:E20S-SDUCR11-D27085mm刀片:DCMT11T304-PS(T9015)被加工材质:S35C流线型刀杆提高36%的刀具寿命100pcs.竞争对手60pcs.加工零件数切削速度:Vc=70~160m/min切深:ap=1.0mm进给:f=0.12~0.2mm/rev切削液:水溶性(内冷)结果和竞争对手的一款中切削槽型相比,PS槽型改善了断屑效果。在稳定的加工条件下,流线型刀杆改善了断屑效果,