| Article Nr.:

编号: Description: 名称: |

22T256

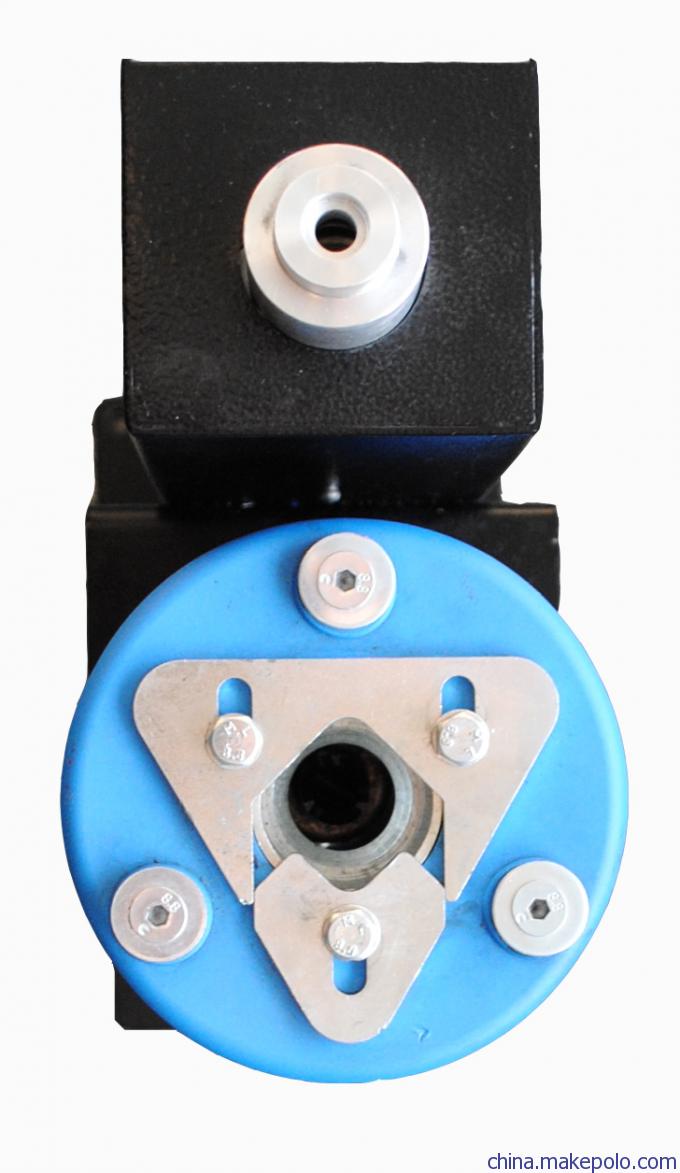

22T256 WHC-H2 Manual torch cleaner WHC-H2机械式焊枪清理单元 |

WHC-H2 mechanized torch cleaning unit is applied to the manual welder, with the functions of cleaning, anti adhesive spray and deposit of one bottle of spray liquid, WHC-H2 makes nozzle cleaning fast, low costs and efficient.

WHC-H2机械式焊枪清理单元用于手工焊机,功能包括喷嘴清理、防飞溅剂喷射与另外一瓶防飞溅剂罐存储,WHC-H2令焊枪清理快速、低成本且有效。

技术描述

WHC-H2 comprises three parts of the mechanized torch cleaner, anti-adhesive-spray, one more spray bottle storage and stand.

WHC-H2 comprises three parts of the mechanized torch cleaner, anti-adhesive-spray, one more spray bottle storage and stand.

WHC-H2 由机械式清枪单元WHC-H2-SP1、防飞溅剂喷射单元WHC-H2-SP2、备用一瓶防飞溅剂罐存储及台架WHC-H2-SP3三部分组成

No electrical connection and no air connection needed.

No electrical connection and no air connection needed.

电力与压缩空气均不需要

Fast, low cost and efficient cleaning of the gasnozzle, manually and easily take the spatter inside the nozzle off within 5 seconds, and fit to any nozzles.

快速、低成本且有效地清理喷嘴,5秒钟内轻松地手动清除掉喷嘴内壁上的飞溅物,适用于任何喷嘴。

Improve the consumable life time and welding quality, particularly keep the welding quality high repeatability due to reliable torch cleaning result.

Improve the consumable life time and welding quality, particularly keep the welding quality high repeatability due to reliable torch cleaning result.

提高易损件的使用寿命和焊接质量,特别是由于可靠的焊枪清理效果,保持焊接质量的高重复性。

Cutter and guiding tube are adjusted to suit the respective gasnozzle.

Cutter and guiding tube are adjusted to suit the respective gasnozzle.

铰刀与导向管均可调节,以适应相应喷嘴

When the torch is applying pressure into the opening, a rotation movement is effected onto the cutter. The rotating cutter scrapes off spatter droplets from gasnozzle and contact tip clearly.

When the torch is applying pressure into the opening, a rotation movement is effected onto the cutter. The rotating cutter scrapes off spatter droplets from gasnozzle and contact tip clearly.

焊枪喷嘴进入导向管,反复下压焊枪,致使铰刀旋转,将喷嘴内部的飞溅物清除掉,电极同时得到清洁。

To ensure maximum cleaning effect, regular spraying of the gasnozzle whit anti-adhesive-spray is important.

To ensure maximum cleaning effect, regular spraying of the gasnozzle whit anti-adhesive-spray is important.

机械清理喷嘴之后,喷射防飞溅剂,确保最佳清枪效果

Only the spraying unit WHC-H2-SP2 can be also applied independently.

Only the spraying unit WHC-H2-SP2 can be also applied independently.

防飞溅单元WHC-H2-SP2 也可以单独使用

The torch cleaning unit WHC-H2-SP1 can be also used independently, furthermore with only 2 bolts mounted easily almost anywhere.

The torch cleaning unit WHC-H2-SP1 can be also used independently, furthermore with only 2 bolts mounted easily almost anywhere.

清枪单元WHC-H2-SP1 也可以单独使用,通过两个螺栓可以非常容易地固定在任何位置。

可以备用一瓶防飞溅剂