|

无铅环保威乐烙铁头 LTI无铅烙铁头 烙铁咀 weller烙铁头 产品描述 |

我们承诺:采购任何一款我司产品,如果出现质量问题,经确认,包退货以免除客户的后顾之忧!同时我厂还制作白光、快克、威乐、高千穗、爱莎等烙铁头,质量可靠。

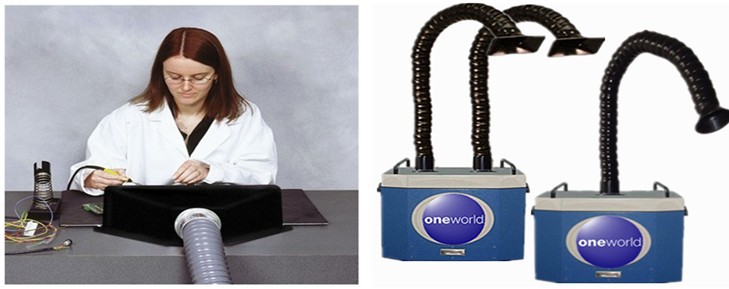

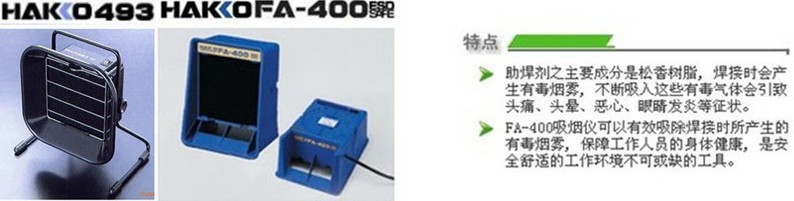

威樂烙鐵頭介紹: 威乐WSD-81专用,型号主要有: 一、烙铁头不上锡的原因 2、 使用不正确或是有缺陷的清洁方法。 3、 使用不纯的焊锡或焊丝中助焊剂中断。 4、 当工作温度超过350℃,而且停止焊接超过1小时,烙铁头上锡量过少。 5、 “干”烙铁头 ,如:焊台开着没有使用,而烙铁头表面没有上锡,会引起烙铁头快速氧化。 6、 使用的助焊剂是高腐蚀性的,从而引起烙铁头快速氧化; 7、 使用中性活性的助焊剂,没有经常清洁烙铁头上的氧化物《解决方法可以用助焊剂泡烙铁头》 Yiworld™系列环保烟雾过滤净化系统专门针对焊锡浸锡沾锡、波峰焊回流炉、激光加工、实验室等各种烟雾、粉尘、微粒、气味的过滤净化。本机特点有吸力大、耗电低、过滤效率高、操作简单、移动灵活等特点,产品已被国内外众多企业所采用。 产品特点: ※欢迎来电咨询:186-0769-5075(谢生)※ different types of materials in the manufacturing process. These fumes are known collectively as Laser Generated Air Contaminants (LGACs). LGACs fall into two categories: particles and gases

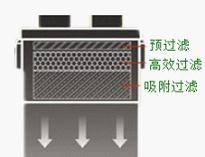

、异味、有毒气体和杀灭部分细菌的作用。滤网又分:集尘滤芯、玻纤滤芯、 HEPA滤芯、活性炭滤芯等。其中最关键就是活性炭滤芯,它能起到分解有毒气体 和杀菌作用,特别是抑制二次污染。产品的特点是风机功能以及滤芯的质量决定 净化效果,机器的放置以及室内布局影响净化是否完全,室内净化效果是否均衡 。滤芯需定期更换。

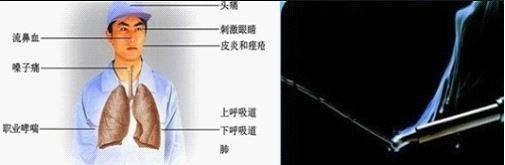

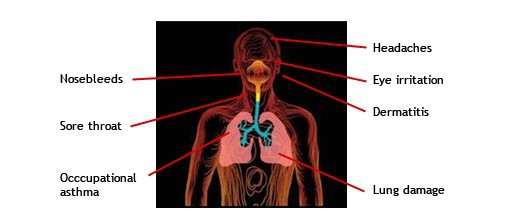

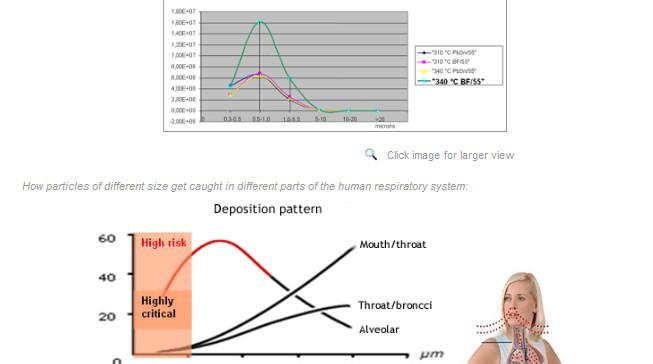

飘浮在空气中在一定的光线照射下人眼可以观察到,即我们能够看到的烟雾。而 另外有5%是以气体方式散发在空气中,我们的肉眼是看不到的,而这些气体中 含有大量的一氧化碳、二氧化碳、甲醇、乙醇、甲烷、甲醛等有害性成分。 喘、慢性支气管炎等症状,严重影响身体健康,同时也影响正常生产。 present in many workplace environments. Operations using lead-free solder, lasers, solvents, and glues are especially at risk. Overexposure can lead to serious – and possibly long term – medical problems.Health difficulties such as nosebleed, eye irritation, and sore throat are occurring with increasing frequency in the workplace, as are incidences of dermatitis, occupational asthma, and, in some cases, permanent lung damage. 购买烟雾净化器与安装大型管道优劣比较: 亿沃电子--专注环保,关注健康. TEL:+86(0)186-0769-5075 Email:world208@163.comQQ:19223 61016 FAX:0769-85024569 更多亿沃Yiworld产品: 买烟雾净化机的理由 界时尚之都尚且如此污染,其他城市可想而知。 污染导致的医疗开支比其他疾病加起来还多2倍。 70%-90%的时间是在室内) 气,比喝水多11倍——宁肯不喝纯净水,也要呼吸纯净气! 过100倍——宁肯不买好房子,也要买净化机! 节食省衣,也要用上净化机! 买亿沃Yiworld烟雾净化机的理由 类第一次有机会轻松地消除烟尘污染。 微粒尤其是铅、镉等重金属穿透细胞进入血液。 ,吸附率率高达99.9%,防止感冒、咳嗽、呼吸道感染、肺炎等疾病及“空调病 ”。 83%活性碳能过滤装修、家具释放的甲醛。开机2个小时就能过滤掉房间里83% 的甲醛,防止白血病、肝癌等致命疾病,并能消除异味。 OCCUPATIONAL ASTHMA limitation and/or airway hyper-responsiveness due to causes and conditions attributable to a particular occupational environment and not to stimuli encountered outside the workplace.” (Bernstein et al 1993) working in those areas. Some of these substances are readily visible or have a distinct odor; others are invisible and odorless. Many are toxic and can lead to allergic reactions, sometimes progressing to occupational asthma. because when a worker develops occupational asthma, they must be removed from the working area, sometimes permanently. In some countries, cases of occupational asthma due to flux fumes and/or isocyanates have already lead to legal claims against employers. Occupational asthma is often indicated by symptoms common to hay fever – an itchy, blocked, or runny nose, often accompanied by sneezing and glazed, itchy, or watering eyes. The transition to lead-free soldering has reduced strain on the environment, but for the operator, the hand soldering process has become more dangerous. The lead in the solder is gone, but to get the solder wire to flow properly, substantially more flux must be used. The temperature needed to create a good solder joint using lead-free solder is also higher, causing a stronger reaction within the flux and creating more solder smoke with a greater number of particles. Lead- free soldering produces up to 250 % more particles between 0.5 and 1.0 microns in diameter, the size that is the most dangerous to inhale. In addition to particles, solder smoke can contain isocyanates, aldehydes, and other unhealthy substances. zone … roughly 20 million particles between 0.3 and 1.0 microns in diameter per cubic foot, or about 700 million particles per cubic meter. How particles of different size get caught in different parts of the human respiratory system: lems that are related to particles and gases in the electronics industry: The following shows exactly what an operator could possibly breathe in during 90 minutes of lead-free soldering. Standard lead-free 3% type ROL1 no-clean flux solder wire was melted continuously with a standard iron. The suction nozzle of a high efficiency fume extraction system was positioned near the tip of the iron. Just 90 minutes later, a nozzle-mounted net had captured a substantial amount of particulates.BEFORE AFTER 90 MINUTES OF PARTICLES Respirable particles – Many particulate LGACs are very small (generally less than 1 micron in diameter), so they can be easily inhaled. Toxic particles – Some particulate LGACs may cause allergic, carcinogenic or toxic effects, such as the chrome and nickel particles produced when working with lasers on stainless steel. Volatile Organic Compounds (VOCs) are often produced when working with lasers on plastics. Many VOCs already have Workplace Exposure Limits in place according to COSHH (control of substances hazardous to health). increased risk of the following health issues: Chronic damage to the nervous system, which can result in concentration and memory impairment, personality changes, and permanent tiredness. Reduced sensitivity to touch Restless arm/leg syndrome Skin dryness and irritation; non-allergic eczema SOLVENT OVERVIEW, TYPES, AND FAQs exposed to them on a daily basis. Everyone working in an industrial environment comes into contact with chemicals that contain solvents. How dangerous the chemicals containing the solvents are depends on the properties of the substances and the precautions taken when handling them. Organic solvents are absorbed primarily through the mucous membranes (total area: 80-200 m²), but some can also be absorbed through the skin (total area approximately 2 m²) or digestive system (total area approximately 10 m²). There is a noticeable trend of people becoming more sensitive to allergic materials, such as airborne particles and solvents, in industrialized societies. This indicates a need for improved extraction equipment and precautions. such as TDI (toluene-2,4-diisocyanate), MDI (diphenyl-methane diisocyanate), and HDI (hexa-methylene diisocyanate) used extensively in industrial workplaces. There are a large number of different isocyanates with different characteristics, but common to all of them is that they cause health problems, especially when inhaled. One of the largest areas of use for isocyanates is in the manufacture of polyurethane plastics (PUR). PUR appears as a soft compact foam and is found in coatings and other chemical products. Approximately 5 % of all plastics used are currently PUR and its usage is increasing. However, during the polymerizing and heating of PUR, a number of isocyanate combinations are formed. When heating phenyl formaldehyde resin, methyl isocyanates are formed. mucous membranes. In contact with water they form amines that will stay in the blood for a long time. Isocyanates are also found in polyurethane materials (coatings), glues, and varnishes. Isocyanates cause health hazards – especially when inhaled in the form of gas, steam, dust, or aerosol droplets. Inhalation can cause irritation in eyes, mucous membranes, and respiratory system with symptoms resembling asthma or bronchitis and decreased lung function. The risk of hypersensitivity is high. Isocyanates can also cause skin irritation. Repeated contact can cause eczema, and in some cases, skin allergy. Isocyanates have a very low limit value … so low that you may be exposed to dangerous concentrations without noticing, as isocyanates are invisible and odorless at low levels. An allergic person can develop problems even when exposed to concentrations below the hygienic limit value. Recently, new health hazards have been discovered with certain PUR coatings and some PUR glues used in the manufacture and repair of printed circuit boards. The same risks occur when working with coated optical cables that contain small amounts of PUR and coated wire. When these materials are heated, isocyanates are formed in such high concentrates that it can cause asthma. It is believed that the thermal segregation starts at 150-200°C. There are also strong reasons to suspect that isocyanates can be formed when heating resin products like fluxing materials. Alcohols Inhalation or skin contact with alcohols such as methanol, ethanol, or isopropanol can cause dizziness, headache, disturbed vision, or fainting. Absorption over a longer period can permanently damage the eyesight of the victim. transformed when heat is applied to them, resulting in fumes that have an irritating effect on the eyes and respiratory organs. Inhalation can induce headache, dizziness, and fainting in severe cases. Esters (acetates) Esters such as ethyl acetate and dioctyl phthalate are often used as solvents and dissolvents in the manufacture of paints, plastics, and synthetic fibers. Like most solvents, they cause irritation of the respiratory passages, but long term exposure causes kidney and liver damage. There are many other solvents in common use, including ketones, mercaptans, organic acids, and ethers, all of which have an effect on the human body, primarily on the respiratory system. Skin contact (splashes) resulting in eczema is a secondary, but fairly common occurrence. FAQs Why are solvents dangerous? Q:Why are solvents dangerous? A: Solvents dissolve fat. The easier they dissolve fat, the easier they are absorbed by the body and the greater their capacity for doing damage. The ability to dissolve fat is partly the reason why solvents are used, and is one of the main reasons why they are so dangerous if they get into your body. works like a sponge in absorbing solvents, this puts the nervous system at great risk. Q:Can the body break down solvents? A:Yes, the liver can break down many of the solvents. But unfortunately, the chemicals formed when these substances are broken down can be even more dangerous than the original solvents. long, in fact, that the body cannot get rid of everything during the night or even over the weekend. This is very serious because it means that solvents can accumulate in your body, sometimes causing irreversible damage. Q:Are all solvents equally dangerous? A: No, some are safer than others. Also, the body absorbs some more slowly than others. If you have a choice of solvents, use one that causes as little harm as possible and is absorbed very slowly. Q:What parts of the body do solvents harm? A:That depends on the solvent in question. The brain, bone marrow, liver, and kidneys are susceptible to damage, but the most common effect is damage to the nervous system. Just as with alcohol (which is a solvent) as the body absorbs more and more of a solvent, reactions become slower and judgment is impaired. In many jobs, those events can open the victim to other, even more extreme dangers. Q: Is the damage done by solvents permanent? A: Unfortunately, in many cases the damage is irreversible. It has been proven that occupational symptoms appear slowly over a long period. By the time a condition is diagnosed, lasting damage may have been caused to the nervous system, respiratory system, eyes, brain, liver, and kidneys. GLUES The main health risks of long-term exposure to glues are: - Skin irritation The level of health risk varies depending on the type of glue being used, with non-hardening glues (“hot glues” that gain strength by cooling) being least dangerous. Glues that strengthen by drying are somewhat more harmful, with water?based glues being less dangerous than solvent?based types. Glues that pose the highest risk of health concerns are “hardening” glues that cure independent of surrounding conditions. HARDENING GLUES – HEALTH CONCERNS released during application. Isocyanates can cause: Asthma vehicle exhaust, tobacco smoke, etc.) acrylate, methacrylate or cyanoacrylate esters that can cause contact allergies. Skin irritation alcohols (alcoxy “methanol”, methoxy), and acetone. These volatile by-products can cause: Cancer Eye irritation exposure. They can cause poisoning through contact, ingestion, or fume inhalation. |