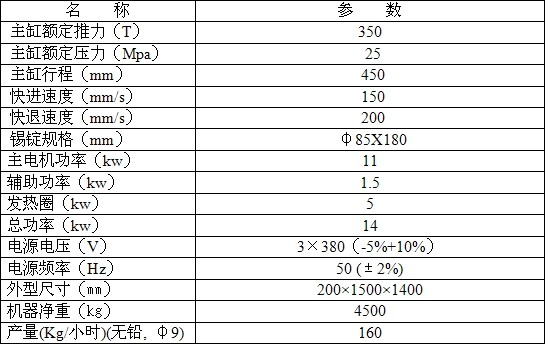

微电脑VT-350T焊锡丝挤压机

微电脑VT-350T焊锡丝挤压机是我司顺应世界焊锡制造业的发展趋势,采用微电脑PLC控制的新机型.

ording to the world’s solder manufacturing business developing trend, we designed our new type micro- computer control VT-350T solder extruder.

一.特点:

在原有配置的基础上,采用微电脑PLC控制,操作时可通过触摸屏(人机界面)对产品工艺参数的要求进行设置及修改.大大提高了机械性能的精确度及自动化.

1) Trait: Based on the original configuration, we adopt puter PLC control. Operator can set & modify the technical parameters of the manufacturing products through the touch-screen. It largely enhanced the precision & automatization of the machine mechanical performance.

二.配置:

2) Configuration

- PLC:采用日本松下可编程控制器,主模块为EC10-2416BTA(晶体管输出),温度模块为: EC10-4TC(四点热电偶).

- 触摸屏:采用台湾台达DOP-A80THTDI (8寸大屏幕PHT LCD)

2. Touch-screen: Adopt Taiwan Delta DOP-A80THTDI (8 inch screen PHT LCD)

三.较常规挤压机的优势: Merits compared with standard extruder:

1.操作简便,自动化程度高. Easy operation, high automatization.

操作技术员可通过触摸屏将不同产品的工艺参数储存至PLC里.作业时,只需选取设定好的生产工艺类别即可自动操作,为企业解决了培训熟手工的烦恼.

Technician can input different technical parameter data into PLC per different products. During operation, simply chose the fixed products data and then it can work automatically. Solved the problem for manufacturer of cultivating skilled workers.

2.采用日本松下可编程控制器,使机械运行更为稳定,使用寿命长.

2. Adopt US Emerson EC10 programmable controllers to ensure better stability & life span of the machine.

3.控制回路为DC24V,对人身和设备更为安全.

3.Control loop designed to DC24V to ensure safety of the people and machine itself.

4.采用精密的EC10-4TC模块温控系统,更精确地控制生产所需的加热温度,温控误差仅为±0.5℃.从而提高了产品质量的稳定性.同时,可设置四组定时开关,具备提前预热功能,使员工上班时即可随时投入工作.

4.Adopt precision EC10-4TC temperature module control system which can have better control of the temperature with tolerance±0.5℃.Only. Thus enhance the stability of the product quality while at the same time it can setting 4 groups timing for pre-heating purpose so as to enable workers to start work immediately once reach factory.

5.微电脑设置故障自动报警配置.当机械出现故障时,可通过PLC快速查出故障根源,大大缩短了维修时间,提高了生产效率.

5. Micro computer control system equip with automatic alarm function. You can check PLC to get the failure root shortly once failure urs in the machine, which will shorten the servicing time and enhance productivity ordingly.