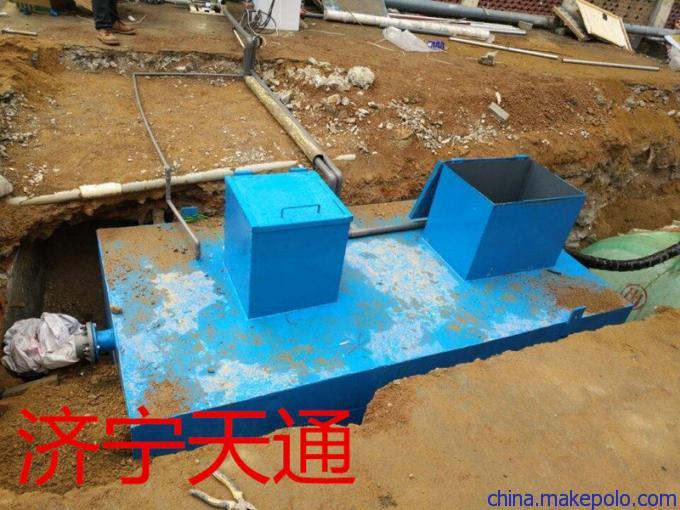

公司简介: 济宁天通水处理设备有限公司业务范围涵盖废水处理、环保设备制作与销售。主要经营:纺织印染废水处理、化工废水处理、制药废水处理、食品加工废水处理、造纸废水处理、养殖废水处理等设备。目前济宁天通的污水处理设备在饮用水、市政污水、医院污水、生活污水、机场污水、高速公路污水、景区污水、食品厂、工业循环冷却水、中水回用等不同领域得到广泛应用。

污水处理设施使用说明

1、臭氧发生器安装人员必须要经过技术培训才能开机维修;

2、使用臭氧机杀菌时,严禁工作人员在浓度较高的臭氧环境中上班和工作;

3、切记设备保养或维修时 处理电源断掉和把臭氧泄气的状态下进行,能够很好的确保人员安全维修;

4、如有异常,请立即断电或者通知专业的人员进行检修。

5、合格的专用接地线,安全可靠的接地,禁止安装在氨气易泄露或有发生爆炸危险的危险区

6、对工艺流程臭氧发生器的应用方法操作人员应知晓,并且能熟练的操作此消毒设备。

7、如发生臭氧泄漏的情况需要第一时间关闭臭氧发生器,并开启通风设备进行通风处理后,即时退出臭氧发生器使用空间,等空间残余臭氧降至安全范围再进入

注意问题

臭氧发生器应用于水处理工程等场合时,有很多因素可能影响发生器的效率及其可靠性,因此在设计臭氧发生器应用系统时必须注意下列问题:

⑴发生器原料气体绝对不得含烃类、腐蚀性气体和任何其他能在氧/臭氧/电晕环境内发生反应,从而对设备安全造成危害或损坏的物质。

众所周知,爆炸的三要素是燃料、氧化剂和火种,而臭氧发生器的电晕环境中已存在两项,即氧化剂和火种。因此必须防止在原料气体中含有烃类燃料物质;如果有可能存在烃类物质,必须安装烃类分析仪,以便当烃类浓度接近爆炸下限(LEl)的25%时切断电源。

碳氟化合物,如特氟隆或冷却剂都可在电晕中分解形成氟,后者能侵蚀玻璃介电材料,可加速介电体损坏。围绕在电晕室外面的循环冷却流体有可能通过密封泄漏并进入电晕空间,结果在介电体表面形成一层漆类,涂层。当发生这种情况时,由于这种涂层降低臭氧生产的效率,介电体必须定期予以清洗。

另外,原料气还应滤除5μm左右的颗粒,以防止小的干燥剂粉末或其他微粒进入发生器电晕区。以免影响电晕效率。

⑵供气压力不能无控制地改变,由于气压影响电晕功率诱导和跨越介电体所加电压,大范围压力变化会使发生器运行不可靠。超出电晕功率范围可造成熔断器或自动断电器断开。超出外加电压峰值还能造成介电体过早失效。

⑶臭氧发生器系统设计时,必须能防止大量水进入到发生器内。

水封供气压缩机用的浮阀或空气干燥器上的凝结水阀阻塞卡住,都会造成发生器电晕室内灌水。电晕室内大量进水可导致电晕集中、高电流密度和局部电介体发热,造成介电体过早失效。即使检测装置在水进入电晕室之前切断电晕电源,水中所含杂质也会沉积在元件表面上,这些杂质必须在继续运行之前予以清除。运行故障或操作错误都能迫使处理出水从臭氧接触池到流至发生器内,至少会造成电晕元件污染或者介电体损坏。此外,系统设计和操作规程必须阻止易燃的腐蚀性气体及从臭氧接触池回流的水蒸气进入发生器内。

⑷冷却水的水质要好,防止结垢,以免影响发生器的散热效果。

二对水冷发生器采说,为使传热表面的结垢最少,冷却水的水质十分重要。结垢会使传热效率降低,从而减少臭氧产量,增加维护费用。在技术上自来水是被优先选择的冷却剂,不过,对大型工业用发生器所需要的耗水量来说,使用自来水经济上毫无吸引力,也许只有发生系统用在水处理厂的情况除外。与自来水水质相反,一般处理后的污水作为冷却水,效果不是很好,因为它容易导致结垢。如果高质量的水或其他流体用在密封的十次冷却回路中,末级热交换器又是专门设计得最少结垢;且便于清洗,而且污水出水还可以作为末级散热使用。为了水费和设备维护费之间的最佳平衡,系统设计时多数采用冷却塔水或热交换器优质饮用水(无悬浮固体、氯化物<5mg/L)。

⑸对于气冷却发生器来说,冷却空气必须无潮气、杂质、腐蚀性、气溶胶、油质或导电物质以及可见粉尘。正常情况下,除非处在一个极度多尘的工业大气环境内,空气多半是不需要过滤处理的。

联系电话:18953768880

联系人:范经理

Company introduction: Jining Tian Tong Shui processing equipment Co., Ltd. covers the business scope of wastewater treatment, environmental protection equipment production and sales. Mainly engaged in: textile printing and dyeing wastewater treatment, chemical wastewater treatment, pharmaceutical wastewater treatment, food processing wastewater treatment, papermaking wastewater treatment, aquaculture wastewater treatment and other equipment. At present, Jining Tian Tong's sewage treatment equipment has been widely applied in drinking water, municipal sewage, hospital sewage, domestic sewage, airport sewage, highway sewage, scenic spot sewage, food factory, industrial circulating cooling water, reclaimed water reuse and other fields.

Instructions for the use of sewage treatment facilities

1, the installation personnel of the ozone generator must be trained by technical training to open the machine.

2. When the ozone machine is used to sterilize, it is strictly forbidden to work and work in the ozone environment with high concentration.

3, remember the equipment maintenance or maintenance treatment power break off and the state of ozone discharge, can be very good to ensure the safety of personnel maintenance;

4. If there is an abnormality, please cut off power immediately or notify professional personnel for maintenance.

5, qualified earthing line, safe and reliable grounding, and prohibited to be installed in dangerous areas where ammonia gas is easily leaked or in danger of explosion.

6. The operating staff of the process ozone generator should know and operate the disinfection equipment skillfully.

7, in case of ozone leakage, we need to shut down the ozone generator for the first time, and open the ventilation equipment to ventilate. After that, we will quit the ozone generator's space and wait for the residual ozone to fall into the safe range.

Pay attention to the problem

The ozone generator is used in water treatment engineering and so on, there are many factors that may affect the efficiency and reliability of the generator, so in the design of the ozone generator application system must pay attention to the following questions:

The raw gas generator is definitely not containing hydrocarbons, corrosive gases and any other in oxygen / ozone / corona environment reaction, thus causing harm or damage to the equipment safety material.

As we all know, the three elements of the explosion are fuel, oxidizer and fire, and there are two items in the corona environment of the ozone generator, that is, oxidizer and fire. Therefore, it is necessary to prevent hydrocarbon fuel materials from being contained in raw materials. If hydrocarbon substances are possible, a hydrocarbon analyzer must be installed, so that the power will be cut off when the hydrocarbon concentration is close to 25% of the lower explosive limit (LEl).

Fluorocarbon, such as Teflon or coolant can be formed from the decomposition of fluorine in the corona, which can erode the glass dielectric material, dielectric damage can be accelerated. The circulating cooling fluid around the corona chamber is likely to leak through the corona and enter the corona space, resulting in the formation of a paint coat on the dielectric surface. When this happens, the dielectric must be cleaned regularly because the coating reduces the efficiency of ozone production.

In addition, the raw gas should also be filtered out of 5 m particles to prevent small drier powder or other particles from entering the generator corona area. In order to avoid the effect of corona efficiency.

The gas pressure can not be changed without control, because the influence of atmospheric pressure on corona power induction and across the dielectric voltage, great changes of pressure will make the generator operation unreliable. Beyond the range of corona power, the fuse or automatic breaker can be disconnected. The prematurely failure of the dielectric can be caused by the excess of the applied voltage peak.

The design of ozone generator system, must be able to prevent a large amount of water into the generator.

The condensate valve on the floating valve or air dryer in the water sealing and air supply compressor is blocked by the condensate valve, which will cause the generator corona chamber irrigation. A large number of influent in the corona chamber can lead to the concentration of corona, high current density and the heating of the local dielectric, resulting in premature failure of the dielectric. Even if the detection device cuts off the corona power before the water enters the corona chamber, impurities in the water will also be deposited on the surface of the components. These impurities must be removed before continuing operation. Operation failures or operational errors can force the treated effluent from the ozone contact pool to flow into the generator, which will cause corona pollution or dielectric damage at least. In addition, the system design and operating procedures must prevent flammable corrosive gases and water vapor reflux from the ozone contact pool into the generator.

The water quality is better cooling water, prevent fouling, so as not to affect the cooling effect of the generator.

Two to the water cooling generator, to make the heat transfer surface fouling least, the water quality of the cooling water is very important. Scaling will reduce heat transfer efficiency, thereby reducing ozone production and increasing maintenance costs. Technically, tap water is the coolant that is selected first. However, for the consumption of water needed for large industrial generators, the use of tap water is economically unattractive, maybe only when the system is used in the water treatment plant. Contrary to water quality, the general treatment of sewage as a cooling water, the effect is not very good, because it easily lead to scaling. If the high quality water or other fluids are used in the ten cooling circuit of the seal, the last stage heat exchanger is specially designed for the least scaling, and it is easy to clean, and the effluent can also be used as the last stage heat dissipation. In order to achieve the best balance between water cost and equipment maintenance cost, most of the drinking water (cooling tower water or heat exchanger) is high quality drinking water (no suspended solids and chloride <5mg/L) in system design.

The gas generator for cooling, the cooling air must be free of impurities, moisture, corrosion, aerosol, oily or conductive material and visible dust. Normally, unless it is in an extremely dusty industrial atmosphere, most of the air does not need to be filtered.

Lian