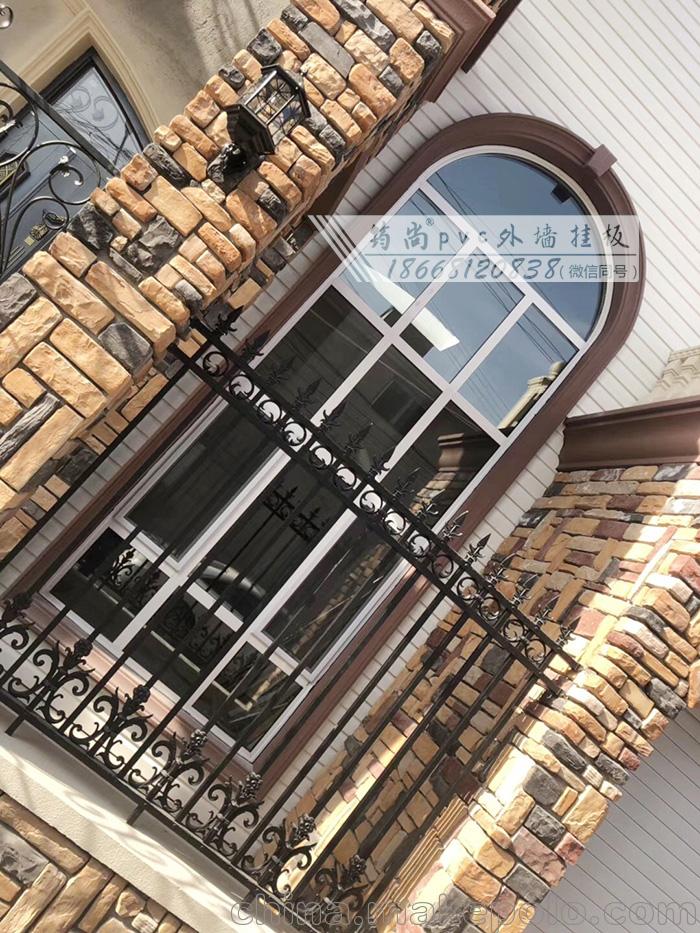

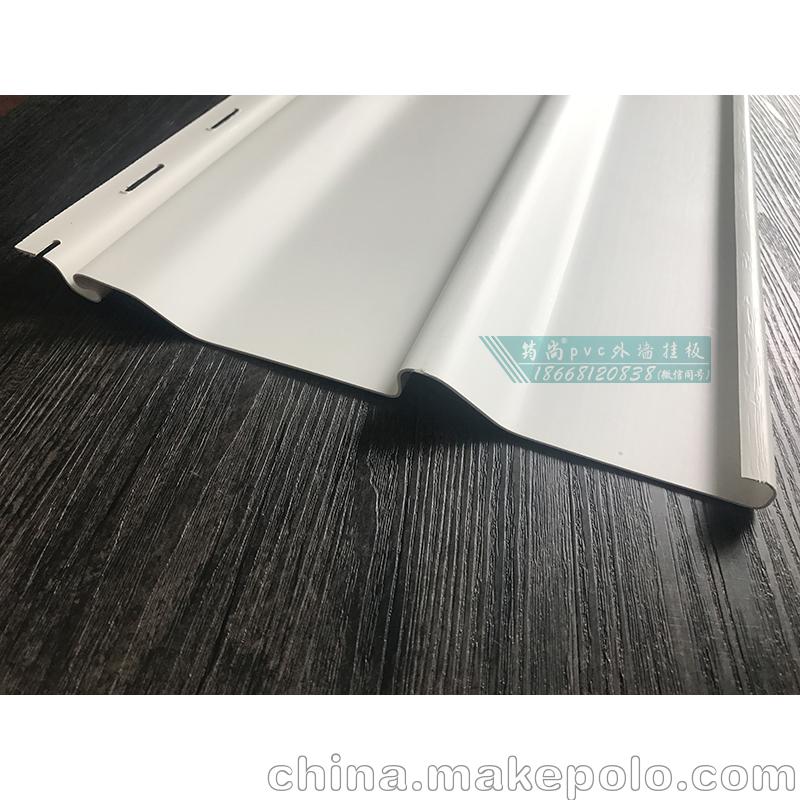

杭州筠尚新材料有限公司氯乙烯树脂是氯乙烯单体经聚合制得的一类热塑性高分子聚合物,分子式为[C2H3CI]a,其中n表示聚合度,一般n590~1500。工业上制备氯乙烯的方法主要有乙块法、联合法、乙烯氧氯化法、乙烯平衡氧氯化法等。乙炔法『乙炔与氯化氢反应生成氯乙烯是最早实现工业化的方法,乙炔可由电石(碳化钙)与水作用制得。此法能耗大,目前用此法生产氯乙烯制造聚氯乙烯树脂厂家主要集中在我国,占我国聚氯乙烯树脂总量的70%こ国量当其,固(2)联合法由石油裂解制得的乙烯经氯化后生成二氯乙烷然后在加压条件下将其加热裂解,脱去氯化氢后得到氯乙烯,副产品氯化氢再与乙炔反应,又制得氯乙烯。mっa08.0一0.0(3)乙烯氧氯化法使用乙烯、氯化氢和氧气反应得到二氯乙烷和水,二氯乙烷再经裂解,生成氯乙烯。副产品氯化氢再回收到氧氯化工段,继续反应。品式0,沿,(4)乙烯平衡氧氯化法是将直接氯化和氧氯化工艺相结合。乙烯与氯反应生成二氯乙烷,二氯乙烷裂解产生氯乙烯和氯化氢。氯化氢与乙烯和氧气反应又生成二氯乙烷,二氯乙烷裂解再产生氯乙烯和氯化氢。氯化氢回收后,继续参与氧氯化反应。本相018-08』事景一,筠尚欧式别墅pvc外墙挂板asa共挤弧形材料防水扣板价格生产厂家,高在工业化生产氯乙烯均聚物时,根据树脂应用領域,一般采用5种方法生产,即本体聚合、悬浮聚合、乳液聚合、微悬浮聚合和溶液聚合,(1)本体聚合法一般采用“两段本体聚合法”,第一段称为预聚合,采用高效引发剂,在62~75℃温度下,强烈搅拌,使氯乙烯聚合的转化率为8%时,输送到另一台聚合釜中,再加入含有低效引发剂的等量新单体,在约60℃温度下,慢速搅拌,继续聚合至转化率达80%时,停止反应本体聚合氯乙烯单体中不加任何介质,只有引发剂。因此,此法生产的聚氯乙烯树脂纯度较高,质量较优,其构型规整,孔鯨率高而均匀,粒度均一。但聚合时操作控制难度大,聚氯乙烯树脂的分子量分布一般较宽。(2)悬浮聚合法液态氯乙烯单体以水为分散介质,并加入适当的分散剂和不溶于水而溶于单体的引发剂,在一定温度下,借助搅拌作用,使其呈珠粒状悬浮于水相中进行聚合。聚合完成后,经磁洗、汽提、离心、干燥得到白色粉末状聚氯乙烯树脂选取不同的悬浮分散剂,可得到颗粒结构和形态不同的两类树脂。国产牌号分为SG-疏松型(“棉花球”型)树脂和XJ-紧密型(“乒乓球”型)树脂。疏松型树脂吸油性好,干流动性佳,易塑化,成型时间短,加工操作方便,适用于粉料直接成型,因而一选用悬浮法聚合的疏松型树脂作为聚氯乙烯制品成型的基础原料目前各树脂厂所生产的悬浮法聚氯乙烯树脂,基本上都是硫松型的。进入20世纪90年代以后,国外先后开发了一些生产氯

杭州筠尚新材料有限公司氯乙烯树脂是氯乙烯单体经聚合制得的一类热塑性高分子聚合物,分子式为[C2H3CI]a,其中n表示聚合度,一般n590~1500。工业上制备氯乙烯的方法主要有乙块法、联合法、乙烯氧氯化法、乙烯平衡氧氯化法等。乙炔法『乙炔与氯化氢反应生成氯乙烯是最早实现工业化的方法,乙炔可由电石(碳化钙)与水作用制得。此法能耗大,目前用此法生产氯乙烯制造聚氯乙烯树脂厂家主要集中在我国,占我国聚氯乙烯树脂总量的70%こ国量当其,固(2)联合法由石油裂解制得的乙烯经氯化后生成二氯乙烷然后在加压条件下将其加热裂解,脱去氯化氢后得到氯乙烯,副产品氯化氢再与乙炔反应,又制得氯乙烯。mっa08.0一0.0(3)乙烯氧氯化法使用乙烯、氯化氢和氧气反应得到二氯乙烷和水,二氯乙烷再经裂解,生成氯乙烯。副产品氯化氢再回收到氧氯化工段,继续反应。品式0,沿,(4)乙烯平衡氧氯化法是将直接氯化和氧氯化工艺相结合。乙烯与氯反应生成二氯乙烷,二氯乙烷裂解产生氯乙烯和氯化氢。氯化氢与乙烯和氧气反应又生成二氯乙烷,二氯乙烷裂解再产生氯乙烯和氯化氢。氯化氢回收后,继续参与氧氯化反应。本相018-08』事景一,筠尚欧式别墅pvc外墙挂板asa共挤弧形材料防水扣板价格生产厂家,高在工业化生产氯乙烯均聚物时,根据树脂应用領域,一般采用5种方法生产,即本体聚合、悬浮聚合、乳液聚合、微悬浮聚合和溶液聚合,(1)本体聚合法一般采用“两段本体聚合法”,第一段称为预聚合,采用高效引发剂,在62~75℃温度下,强烈搅拌,使氯乙烯聚合的转化率为8%时,输送到另一台聚合釜中,再加入含有低效引发剂的等量新单体,在约60℃温度下,慢速搅拌,继续聚合至转化率达80%时,停止反应本体聚合氯乙烯单体中不加任何介质,只有引发剂。因此,此法生产的聚氯乙烯树脂纯度较高,质量较优,其构型规整,孔鯨率高而均匀,粒度均一。但聚合时操作控制难度大,聚氯乙烯树脂的分子量分布一般较宽。(2)悬浮聚合法液态氯乙烯单体以水为分散介质,并加入适当的分散剂和不溶于水而溶于单体的引发剂,在一定温度下,借助搅拌作用,使其呈珠粒状悬浮于水相中进行聚合。聚合完成后,经磁洗、汽提、离心、干燥得到白色粉末状聚氯乙烯树脂选取不同的悬浮分散剂,可得到颗粒结构和形态不同的两类树脂。国产牌号分为SG-疏松型(“棉花球”型)树脂和XJ-紧密型(“乒乓球”型)树脂。疏松型树脂吸油性好,干流动性佳,易塑化,成型时间短,加工操作方便,适用于粉料直接成型,因而一选用悬浮法聚合的疏松型树脂作为聚氯乙烯制品成型的基础原料目前各树脂厂所生产的悬浮法聚氯乙烯树脂,基本上都是硫松型的。进入20世纪90年代以后,国外先后开发了一些生产氯乙烯单体的新工艺。例如,开发出不产生水的直接氯化氯化氢氧化工艺;使用最便宜的乙烷作原料,直接氧氯化生产氯

乙烯单体的技术;二氯乙烷/纯碱工艺生产氯乙烯单体的新技术等。

Vinyl chloride resin is a kind of thermoplastic polymer prepared by polymerization of vinyl chloride monomers. The molecular formula is [C2H3CI]a, where n represents degree of polymerization and general n

From 590 to 1500.The main methods of preparing vinyl chloride in industry are: block method, combined method, ethylene oxychloride method, ethylene balanced oxychloride method, etc.Acetylene method "acetylene react with hydrochloric acid to produce vinyl chloride was among the first to realize industrialization, the method of acetylene by calcium carbide, calcium carbide and water. This method, large energy consumption of the current production of vinyl chloride manufacture PVC resin manufacturer mainly concentrated in this way in our country, accounting for 70% of the total PVC resin in our country amount when its こ countries, (2) joint fixation method of ethylene by petroleum cracking after chloride generated dichloroethane and under pressurized conditions its heat cracking, vinyl chloride, after take off hydrogen chloride by-product hydrogen chloride reacts with acetylene, and system of vinyl chloride. M っ a08.0 a 0.0 (3) the chlorination process using ethylene vinyl oxygen, hydrochloric acid and oxygen reaction dichloroethane and water, dichloroethane and cracking, produce vinyl chloride. The by-product hydrogen chloride recycle to oxychlorination section, continue to respond. Product type 0, along, (4) vinyl chloride chlorination process is the direct chlorination equilibrium oxygen and oxygen process. The combination of ethylene and chlorine reacts dichloroethane, dichloroethane pyrolysis produce vinyl chloride and hydrochloric acid. Hydrochloric acid with ethylene and oxygen reaction and generating dichloroethane, dichloroethane pyrolysis to produce vinyl chloride and hydrochloric acid. After hydrochloric acid recovery, continue to participate in oxychlorination reaction. Japan's 018-08 "scene a delta

High in the industrialized production of vinyl chloride homopolymer, according to the resin application field, generally by adopting the method of five kinds of production, namely, bulk polymerization, suspension polymerization, emulsion polymerization, suspension polymerization and solution polymerization, (1) body polymerization generally adopt "two period of polymerization of ontology", the first paragraph is called pre-aggregated, adopt efficient initiator, at 62 ~ 75 ℃ temperature, strong stirring, made of vinyl chloride polymerization conversion rate was 8%, transfer to another in the polymerizer, add amount of monomers containing efficient initiator, at about 60 ℃ temperature, slow stirring, continue to aggregate to the conversion rate of 80%, bulk polymerization of vinyl chloride single stop reactionIn the body without any medium, only initiator.Therefore, the polyvinyl chloride resin produced by this method has higher purity, better quality, regular configuration, high pore-whale ratio and uniform particle size.However, it is difficult to control the polymerization, and the molecular weight distribution of polyvinyl chloride resin is generally wide.(2) suspension polymerization of liquid vinyl chloride monomer with water as the dispersion medium, and adding appropriate dispersant and insoluble in water but soluble in monomer initiator, at a certain temperature, with the help of stirring, make it suspended in the water phase as beads for polymerization.After the polymerization was completed, the white powder polyvinyl chloride resin was obtained by magnetic washing, stripping, centrifugation and drying. Two kinds of resin with different particle structure and morphology could be obtained by selecting different suspension dispersants.Domestic brands are pided into SG- loose (" cotton ball ") resin and XJ- tight (" table tennis ") resin.Loose type oil absorption resin is good, do good liquidity, easy plasticization and molding time is short, processing and easy to operate, suitable for direct molding powder, thus a selection of loose aggregation suspension method resin as raw materials for the PVC products forming the basis of different resin factory is the production of PVC resin suspension method, are basically of the sulfur loose type.After entering 20 centuries 90 time, abroad developed a few production chlorine successively

New process for vinyl monomer.For example, the direct chlorination and hydrochlorination oxidation process without producing water was developed.Chlorine is produced by direct oxychlorination using the cheapest ethane as raw material

Technology for vinyl monomers;New technology of producing vinyl chloride monomer by dichloroethane/soda.