VD TMF 系统用作除固体,降低SDI

VD Tubular Membrane Filter Modules for Solids / SDI Reduction

为什么选择VD TMF来去除固体/SDI?

Choosing Tubular Membrane Filter Modules (TMF) for Silt Density / Solids Reduction Removal

用于降低悬浮固体的主要两种工艺是澄清池和介质过滤。澄清池由于要求的监控以阻止因为温度和化学改变而导致的大量固体流出。在澄清池中用的有机絮凝剂(用于促进絮凝)也能导致麻烦。过剩的絮凝剂将污堵如,RO膜的过滤设备。由于这些絮凝剂是有机的,它们将是一种潜在的微生物营养源,会使下游管路和设备产生微生物生长和污堵。

反渗透膜要求阻止颗粒物,在大多数情况下,小分子或亚颗粒尺寸的分散颗粒不能充分被多介质过滤器、筒式过滤器和袋式过滤器去除。如果用筒式过滤器和袋式过滤器,需要经常更换,所以所需的费用和人工太多。过高的SDI会降低RO系统性能,堵塞和污堵RO膜,使清洗频率增加,从而缩短RO组件的寿命。很多情况下,这些预过滤是困难的,而用TMF却很适用。

The two (2) main technologies used to reduce suspended solids are clarification or media filtration. Clarifiers require continual supervision because they require a high level of monitoring and to prevent the passing large slugs of solids based upon temperature and chemistry changes. The organic polymers used in clarifiers (used to promote flocculation) can also cause problems. An excess of these polymers will foul downstream filtration equipment such as RO membranes or Nanofilters. Since these polymers are organic,they present a potential food source of bacteria which resulting biological growth and biofouling of piping and downstream equipment.

Reverse osmosis and Nanofiltration systems require protection from particulates and in many cases there are particle dispersions in the low or submicron size range that are not adequately handled by multimedia, cartridge or bag filtration. In the case of cartridge or bag filtration, change outs need to occur so frequently that it is cost prohibitive and labor intensive when trying to reduce the SDI (Silt Density Index) to an adequate level. Failure to reduce the level of the SDI will result in poor system performance, plugging and fouling of the RO membrane, increased cleaning frequency and therefore a reduced lifespan of the RO modules. These situations translate into higher operating costs. In most cases where these difficult prefiltration conditions occur, the problem would best be addressed with a microfiltration system using VD Tubular Membrane Filter Modules (TMF).

怎样设计去除固体的VD TMF系统

Designing a TMF System for Solids/SDI

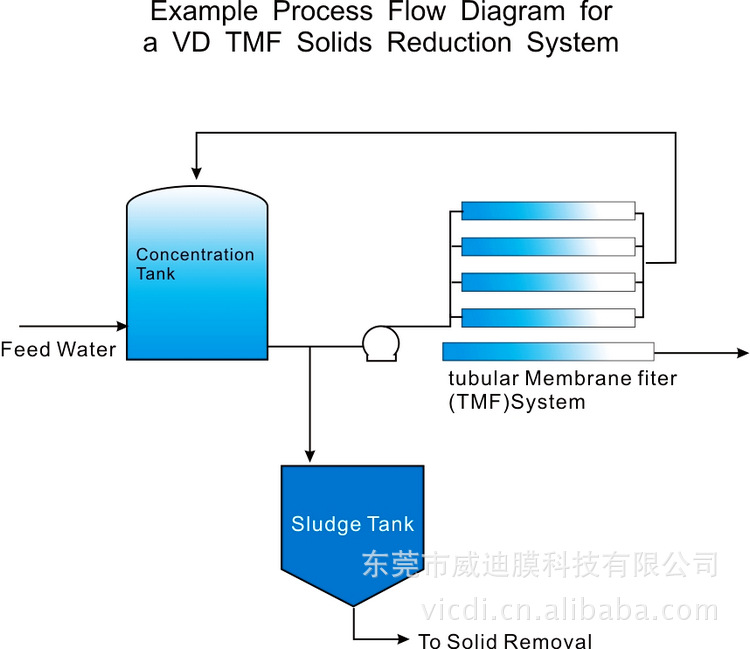

TMF系统和RO系统相似,有提升泵、管道、阀门,TMF组件固定在钢架上。

The TMF systems are very similar to Reverse Osmosis systems, where a booster pump, piping, valves and TMF elements are mounted to a steel frame. See Figure 3 and 4 to see how the process is typically designed and what a typical TMF system looks like.

典型的工艺设计和系统见图1

典型工程图2

一般,75-95%的水通过后进入RO系统,浓水循环回TMF前面再次稀释。固体浓度保持在3-5%,剩余固体经压滤机进一步处理或处置。要求的TMF组件数量取决于系统要求的总产水量和最多只能串联12个组件的限制。TMF的排列组数要满足最少一组要求清洗时的要求。用一个小型中试系统测试是确定通过膜组件的理想通量和确定导致组件需清洗的因素(如胶体)的好方法。

Typically, between 75 and 95% of the water passes through as permeate and is sent to the RO or Nanofilter system. The concentrate is recycled up stream of the Tubular Membrane Filter Modules at the Concentration Tank for re-dilution. Solids concentration is kept at 3-5% with the excess solids sent to a filter press for de-wetting or to disposal. The number of Tubular Membrane Filter Modules required is dependent upon the total flow rate of the system needed and the modules are typically placed in series of up to 12 modules. Systems are designed to allow at least one train or series of modules to be available for further cleaning if required. It is always best to run a small pilot test system as a means of determining the ideal flux rates through the modules and identify any issues, such as colloids, that might require further module cleaning.

VD TMF组件的寿命有多长?

How long will TMF modules last?

TMF典型的寿命是3-5年或更久,整个TMF系统可以用20年设计。TMF组件所应用的PVDF膜和PVDF/HDPE支撑是非常坚固的,耐磨擦、耐高温、pH在0-14间不会降低其截留固体的能力。

The typical lifespan of a Tubular Membrane Filter Module is 3 to 5 years or longer with the total TMF system designed for approximately 20 years of operation. The PVDF membranes and the PE or PVDF substrates used in the Tubular Membrane Filter Modules are extremely robust. They are designed to withstand harsh environments and will resist abrasion, high temperature, and pH environments from 0-14 without a decrease in retention efficiency.

总结:

Summary

VD TMF应用快速增长的原因主要有:

Tubular Microfiltration or Ultrafiltration systems using VD Tubular Membrane Filter Modules offer:

1.易于运行维护和控制;

Easy operation, maintenance and control;

2.耐磨擦和抗温度波动;

Continuous operation and performance;

3.可以连续运行,良好的性能;

Resistance to abrasion and temperature fluctuations;

4.高的膜通量.

High flux rates.

当用来降低进RO的SDI时,TMF系统将对RO系统的性能有重要的改善---一般会延长RO组件的寿命,减少其污堵/清洗的频率,同时它比经常更换袋式过滤或筒式过滤经济。对于固体的去除,TMF与澄清池相比,具有占地小、受温度变化的影响小、要求的楼层间的空间小等优点。TMF是一种能处理含高固体浓度的工艺水的过滤工艺,相比其它的膜工艺有巨大的优势。

When used to reduce SDI to an RO or Nanofilter, operating a Tubular Membrane Filter Module system will yield a significant process improvement, typically resulting in much longer RO or Nanofilter module life and reduced cleaning frequency. Tubular Membrane Filter Modules provide a cost effective alternative to changing filter bags or cartridge filters on a daily basis. For solids removals, TMF systems offer a compact alternative to bulky clarifiers which are greatly affected by temperature changes, require significant floor space. TMF is a filtration technology that can handle process streams with a high solids concentration that presents a challenge to other membrane based technologies.

图3典型的TMF系统

联系方式

东莞市威迪膜科技有限公司

公司网址:www.vicdi.com 公司邮箱:vicdi@vicdi.com 公司热线:4000-222-515 公司地址:广东省东莞市虎门镇村头管理区团结大道