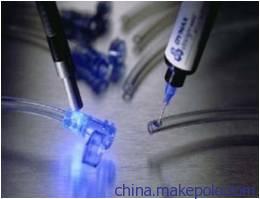

TU3306:是一种单组份,紫外光固化,丙烯酸树脂类胶粘剂,波长在200-400nm时能够快速固化,该产品使用方便,能极大的提高效率和产品稳定性。本产品主要应用于电子元器件、IC四脚定位、连接器和电路板排线的粘接,密封、防潮,绝缘,保护与固定。

TU1500:是一种单组份,紫外光固化,丙烯酸树脂类可达到光学级胶粘剂,波长在200-400nm时能够快速固化,该产品透光率折射率高耐黄变好,能极大的提高效率和产品稳定性。本产品主要应用于光学显示屏、镜头的粘接,密封、防潮,绝缘,保护与固定。

一、PRODUCT DESCRIPTION

| Technology | l Acrylic |

| Chemical Type | l Acrylated urethane |

| Appearance | l Transparent to slightly hazy liquid |

| Components | l One component - requires no mixing |

| Cure | l Ultraviolet (UV)/ visible light |

| Application | l Bonding |

Specific Gravity @ 25 °C 1.13

Refractive Index 1.48

Viscosity, Brookfield - RVT, 25 °C, mPa•s (cP):

Spindle 5, speed 20 rpm 8,000 to 14,500

三.TYPICAL CURING PERFORMANCE

Themis TV8000 can be cured by exposure to UV and/or visible light of sufficient intensity. To obtain full cure on surfaces exposed to air, radiation @ 220 to 260 nm is also required. The speed of cure will depend upon the UV intensity and spectral distribution of the light source, the exposure time and the light transmittance of the substrates.

Stress Cracking: Liquid adhesive is applied to a polycarbonate bar 6.4 cm by 13 mm by 3 mm which is then flexed to induce a known stress level. Stress Cracking, ASTM D 3929, minutes:

17 N/mm² stress on bar: >15

Fixture Time:

Fixture time is defined as the time to develop a shear strength of 0.1N/mm² .

UV Fixture Time, Glass microscope slides, seconds:

Black light, Zeta® 7500 light source; 6 mW/cm² , measured @ 365 nm: ≤18

Metal halide bulb (doped), Zeta®7400;30 mW/cm² , measured @ 365 nm: 5 to 10

Electrodeless, H & V bulbs; 50 mW/cm² , measured @ 365 nm: <5

Electrodeless, D bulb:50 mW/cm² , measured @ 365 nm: <5

四.TYPICAL PROPERTIES OF CURED MATERIAL

Cured @ 30 mW/cm², measured @ 365 nm, for 80 seconds using a glass filtered metal halide light source

Physical Properties:Shore Hardness, ISO 868, Durometer D 51 Refractive Index 1.5 Water Absorption, ISO 62, %:2 hours in boiling water 2.72 Elongation, at break, ISO 527-3, % 260 Tensile Modulus, ISO 527-3 N/mm² 207 Tensile Strength, at break, ISO 527-3 N/mm² 17 Surface Resistivity, IEC 60093, Ω∙cm 8.7×1014 Volume Resistivity, IEC 60093, Ω•cm 8.9×1014

五.TYPICAL PERFORMANCE OF CURED MATERIAL:

Adhesive Properties

Cured @ 30 mW/cm² , measured @ 365 nm,for 80 seconds using a metal halide light source, (samples with 0.5 mm gap).

Lap Shear Strength, ISO 4587; Polycarbonate: N/mm² 207 (psi) (1,600)

六.Directions for use:

1、This product is light sensitive; exposure to daylight, UV light and artificial lighting should be kept to a minimum during storage and handling.

2、The product should be dispensed from applicators with black feedlines.

3、For best performance bond surfaces should be clean and free from grease.

4、Cure rate is dependent on lamp intensity, distance from light source, depth of cure needed or bondline gap and light transmittance of the substrate through which the radiation must pass.

5、Recommended intensity for cure in bondline situation is 5mW/cm² minimum (measured at the bondline) with an exposure time of 4-5 times the fixture time at the same intensity.

6、For dry curing of exposed surfaces, higher intensity UV is required (100 mW/cm² ).

七、Storage:

Store product in the unopened container in a dry location.Storage information may be indicated on the product container labeling. Optimal Storage:8 °C to 21 °C. Storage below 8 °C or greater than 28 °C can adversely affect product properties. Material removed from containers may be contaminated during use. Do not return product to the original container. Themis Corporation cannot assume responsibility for product which has been contaminated or stored under conditions other than those previously indicated. If additional information is required, please contact your local Technical Service Center or Customer Service Representative.